Sure, here are some frequently asked questions (FAQ) along with their respective answers for manufacturing a 3-side seal packaging machine quality work from the SourcifyChina factory:

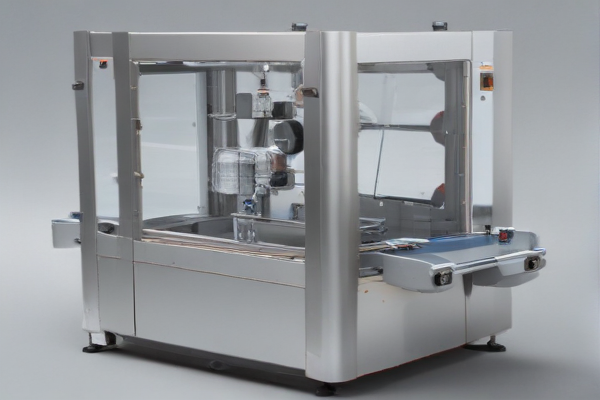

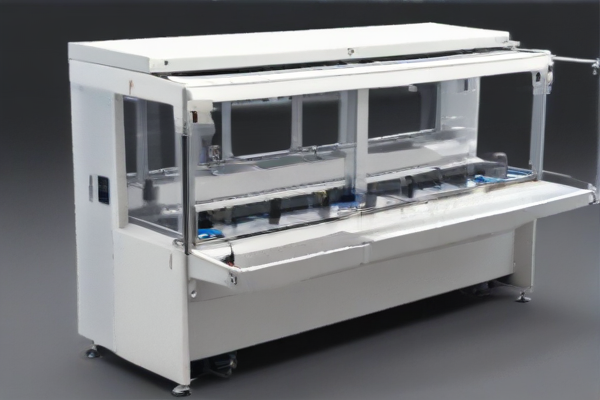

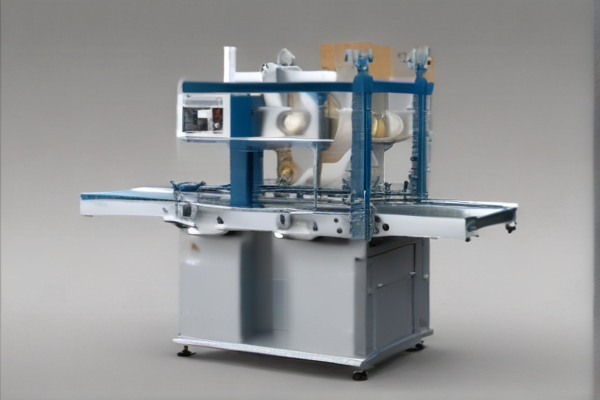

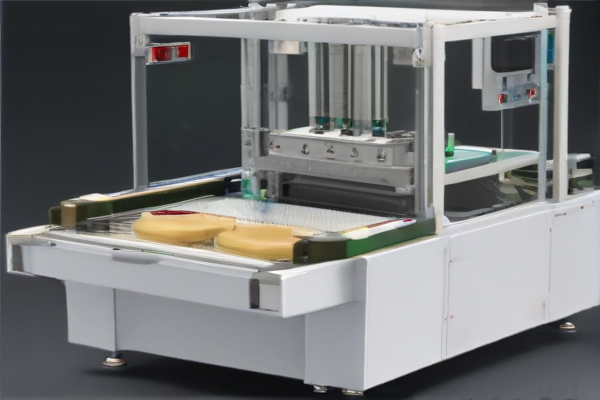

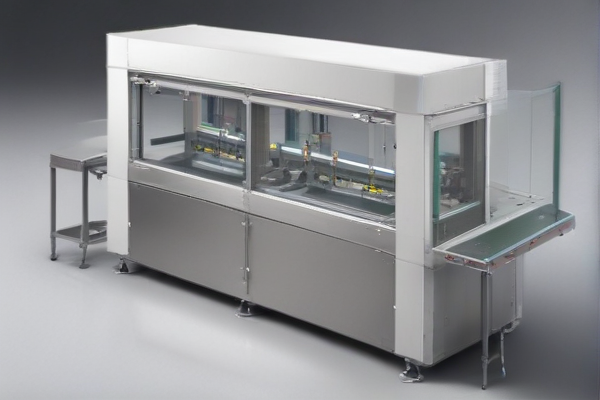

Q: What is a 3-side seal packaging machine?

A: A 3-side seal packaging machine is designed to create pouches that are sealed on three sides, leaving one side open for filling products. It is widely used for packaging snacks, pharmaceuticals, and various other products.

Q: Why should I choose SourcifyChina factory for manufacturing?

A: SourcifyChina has a proven track record of producing high-quality packaging machines with advanced technology, competitive pricing, and excellent customer support.

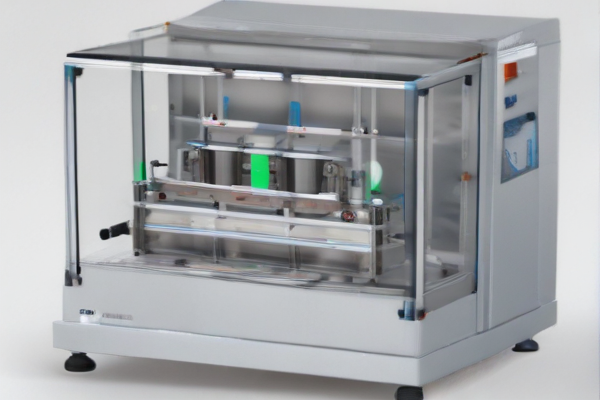

Q: What materials can the 3-side seal packaging machine handle?

A: These machines can handle a variety of packaging materials including plastic films, aluminum foil, and laminated films.

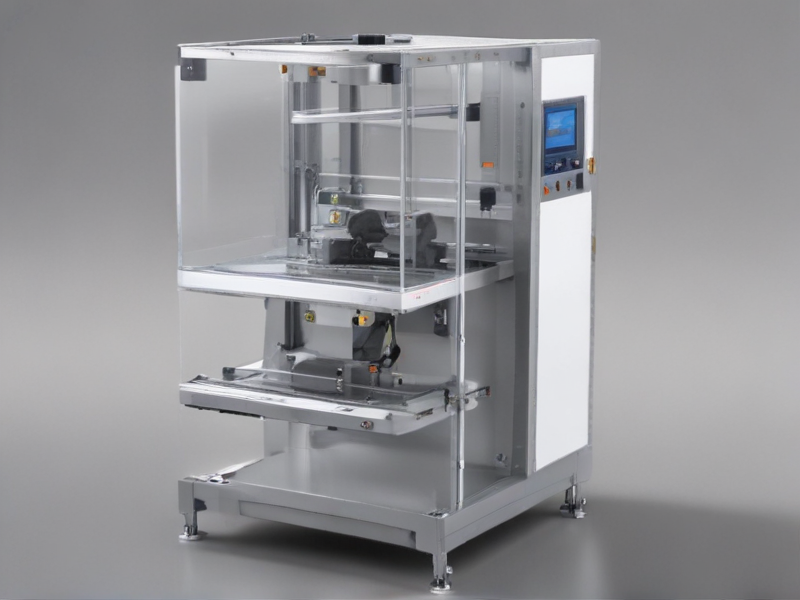

Q: Can the machine be customized to meet specific requirements?

A: Yes, SourcifyChina offers customization options to meet specific client requirements such as size, capacity, and additional features.

Q: How long does it take to manufacture and deliver the machine?

A: The lead time usually depends on the complexity of the customization. Generally, it takes around 6-8 weeks from order confirmation to delivery.

Q: What kind of quality control measures are in place at SourcifyChina?

A: SourcifyChina employs stringent quality control measures including raw material inspection, in-process quality checks, and final product testing to ensure superior machine quality.

Q: Are there training and support services available?

A: Yes, SourcifyChina provides comprehensive training for machine operation and maintenance along with prompt after-sales support services.

Q: What is the warranty period for the 3-side seal packaging machine?

A: Typically, the machine comes with a one-year warranty covering parts and labor.

Q: How energy-efficient are these machines?

A: The machines are designed to be energy-efficient, incorporating the latest technology to minimize energy consumption without compromising performance.

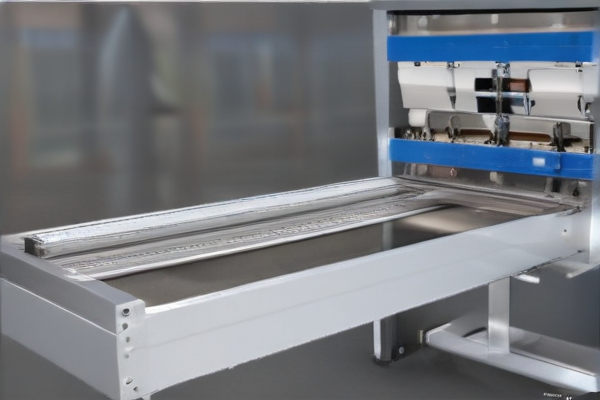

Q: What maintenance is required for the 3-side seal packaging machine?

A: Regular maintenance includes cleaning, lubrication, and periodic inspection of mechanical and electronic components to ensure optimal performance and longevity.