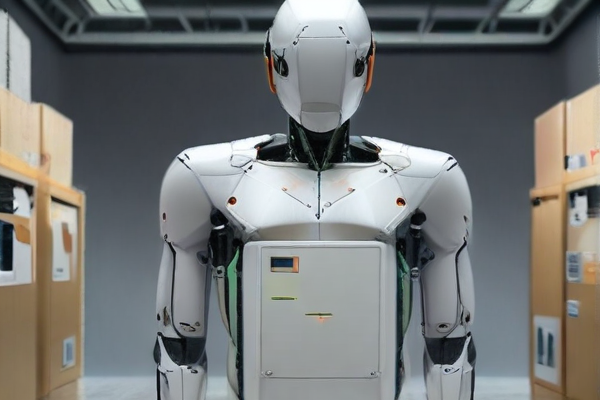

Automated systems streamline various tasks across industries by minimizing human intervention. They can range from simple programmable devices to sophisticated AI-driven solutions, each offering unique capabilities tailored for different operational needs.

– Home Automation: Smart thermostats, lighting, security systems using IoT.

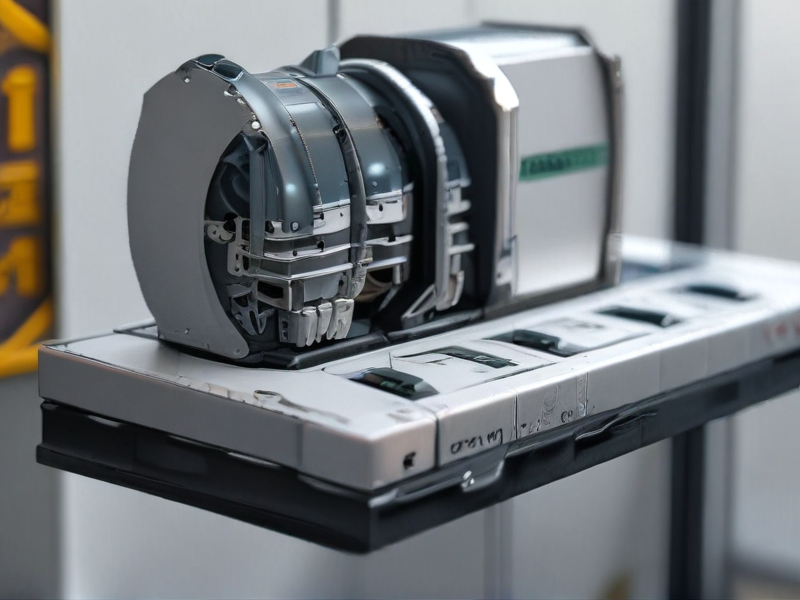

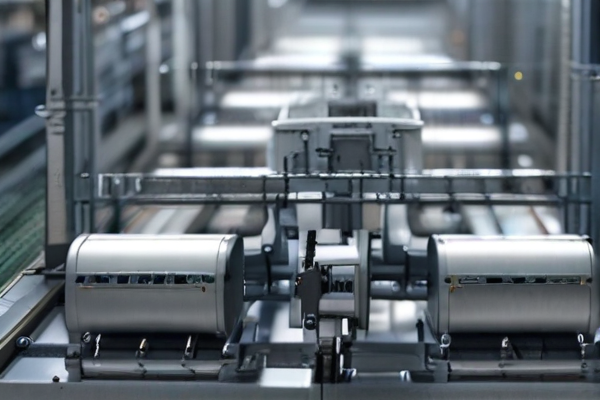

– Industrial Automation: Robotics, PLCs (Programmable Logic Controllers), distributed control systems.

– Business Process Automation: Accounting software, customer service chatbots, HR systems.

– Healthcare Automation: Automated diagnostic tools, robotic surgery systems, patient monitoring.

– Retail Automation: Self-checkout kiosks, inventory management systems, personalized marketing.

– Transportation Automation: Autonomous vehicles, smart traffic management, drone delivery systems.

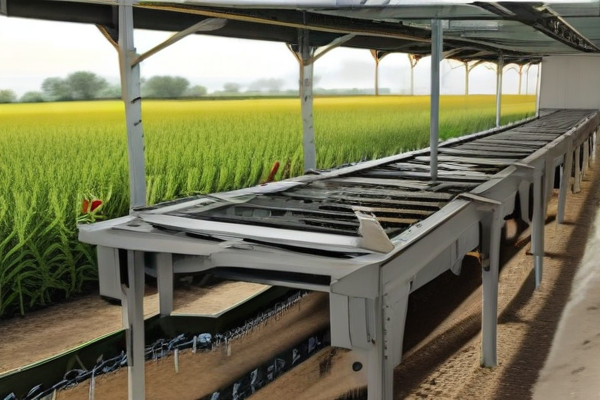

– Agricultural Automation: Automated irrigation systems, drone crop monitoring, robotic harvesters.

– Energy Management: Smart grid technology, automated energy distribution, predictive maintenance.

– Building Automation: HVAC systems, security, lighting based on occupancy.

– Telecommunications: Network monitoring, automated support systems, traffic management.

– Financial Services Automation: Robotic Process Automation (RPA) for transactions, fraud detection systems.

– Manufacturing: CNC machines, assembly line robots, quality control systems.

– Educational Technology Automation: Automated grading systems, online course management, personalized learning algorithms.

– Travel and Tourism: Online booking systems, virtual customer service agents, automated itinerary planning.

– Logistics and Supply Chain: Warehouse robots, automated sorting systems, real-time tracking.

Each type improves efficiency, reduces error rates, and enhances service delivery, propelling industries towards greater innovation and productivity.