Here are some frequently asked questions (FAQ) along with their answers for manufacturing a “weight checking machine quality work from SourcifyChina factory”:

Q1: What types of weight checking machines does SourcifyChina manufacture?

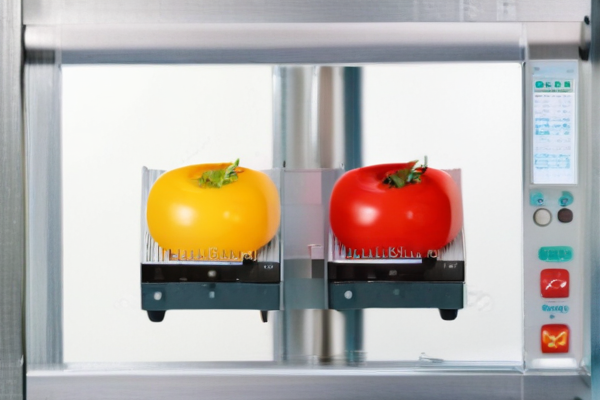

A1: SourcifyChina manufactures a variety of weight checking machines, including conveyor belt weighers, checkweighers, and static weighing scales designed for assorted industries like food processing, pharmaceuticals, and packaging.

Q2: What is the typical lead time for production and delivery?

A2: The typical lead time for manufacturing and delivery is approximately 6-8 weeks, depending on the complexity of the equipment and current production schedules.

Q3: How does SourcifyChina ensure the quality of its weight checking machines?

A3: SourcifyChina adheres to strict quality control measures including ISO certifications, rigorous testing procedures, and continuous quality monitoring throughout the manufacturing process.

Q4: Can the weight checking machines be customized according to specific requirements?

A4: Yes, SourcifyChina offers customization options to meet the particular needs of various clients, including specific dimensions, software integration, and additional features.

Q5: What after-sales support and services are available?

A5: SourcifyChina provides comprehensive after-sales support including installation assistance, training, maintenance services, and a warranty period for all weight checking machines.

Q6: Are there any software solutions included with the weight checking machines?

A6: Yes, the machines come with integrated software solutions for data collection, reporting, and analysis to ensure optimal performance and compliance with industry standards.

Q7: What are the main industries served by SourcifyChina’s weight checking machines?

A7: Key industries served include food and beverage, pharmaceuticals, logistics, and packaging.

Q8: How can I request a quote or place an order?

A8: To request a quote or place an order, you can visit SourcifyChina’s official website, contact their sales team via email, or call their customer service hotline for immediate assistance.

Q9: What payment terms are available?

A9: SourcifyChina offers various payment terms including T/T (Telegraphic Transfer), L/C (Letter of Credit), and other arrangements as per mutual agreement.

Q10: Are there any certifications or approvals for the weight checking machines?