Sure, here is a list of FAQs for the manufacturing quality of a pre-roll machine from SourcifyChina factory.

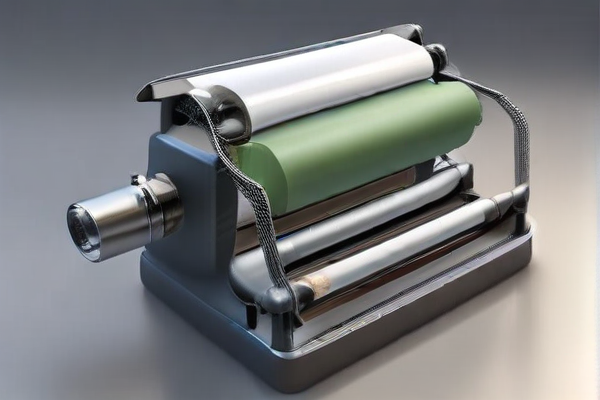

1. What is the production capacity of the pre-roll machine?

The pre-roll machine from SourcifyChina’s factory can produce up to 1,000 pre-rolls per hour, depending on the specific model and configuration.

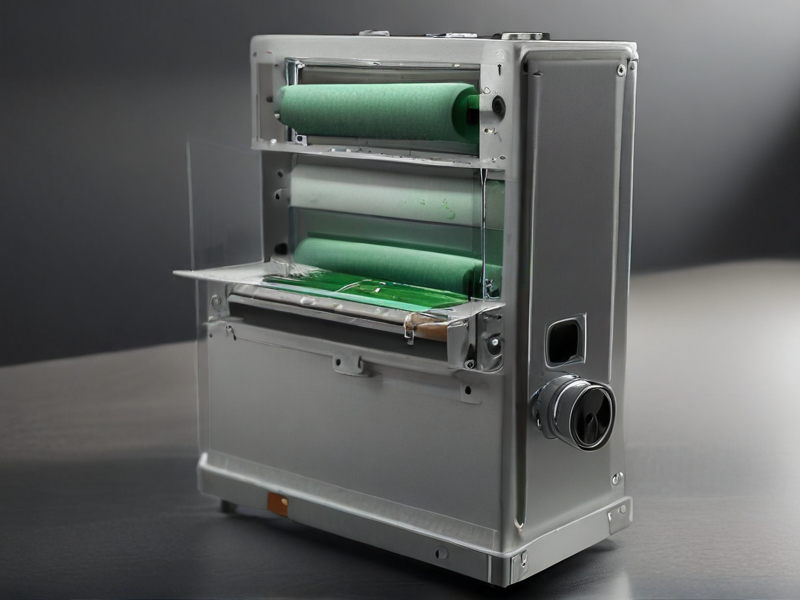

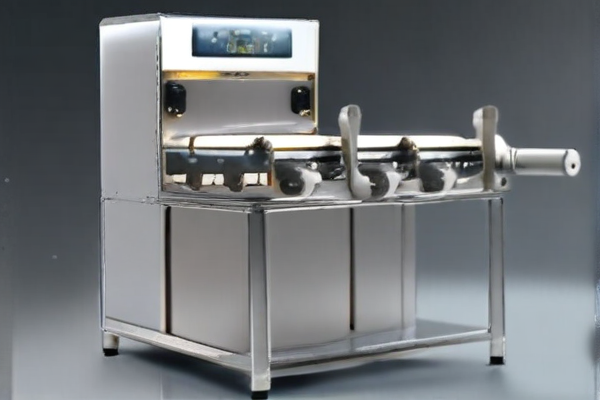

2. What materials are used in the construction of the pre-roll machine?

Our pre-roll machines are constructed using high-quality stainless steel and food-grade materials that meet international standards to ensure durability and safety.

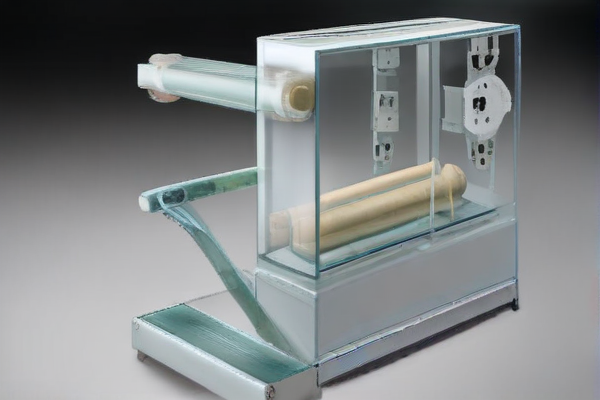

3. Is the machine easy to operate?

Yes, the pre-roll machine is designed for ease of use, featuring a straightforward interface and simple controls. Comprehensive training and user manuals are provided to ensure smooth operation.

4. What kind of maintenance is required?

Regular maintenance involves cleaning and occasional lubrication of moving parts. We provide detailed maintenance guidelines and offer ongoing support to minimize downtime and ensure long-term efficiency.

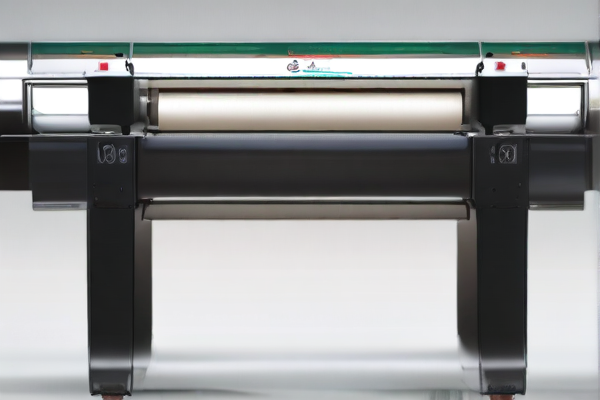

5. Can the machine handle different sizes of cones?

Yes, our pre-roll machines are versatile and can be adjusted to accommodate various cone sizes, making them suitable for different product specifications.

6. How does SourcifyChina ensure the quality of the machines?

Quality assurance is our top priority. Each machine undergoes rigorous testing and inspection throughout the manufacturing process to meet high standards. We are ISO certified and employ stringent quality control measures.

7. Is there a warranty on the pre-roll machine?

Yes, SourcifyChina provides a one-year warranty on all pre-roll machines, covering parts and labor. Extended warranty options are also available upon request.

8. Can the machine be customized?

Absolutely, we offer customization services to meet specific client needs, including modifications in size, capacity, and additional features.

9. What support is available after purchase?

We offer comprehensive after-sales support, including remote troubleshooting, on-site service, and access to spare parts. Our dedicated support team is available 24/7 to assist you.

10. How long does it take to receive the machine once an order is placed?

Delivery times vary based on order specifications and quantity, but typical lead times range from 4 to 8 weeks. Expedited services may be available for urgent orders.

These FAQs should cover most basic inquiries about the pre-roll machine quality and services provided by SourcifyChina factory.