Sure, here is a list of FAQs with their answers for sourcing a pre-roll machine from SourcifyChina Factory:

Q: What is the minimum order quantity (MOQ) for a pre-roll machine from SourcifyChina Factory?

A: The minimum order quantity (MOQ) generally starts at one unit, but discounts may be available for bulk orders. It’s best to contact SourcifyChina Factory directly for specific details.

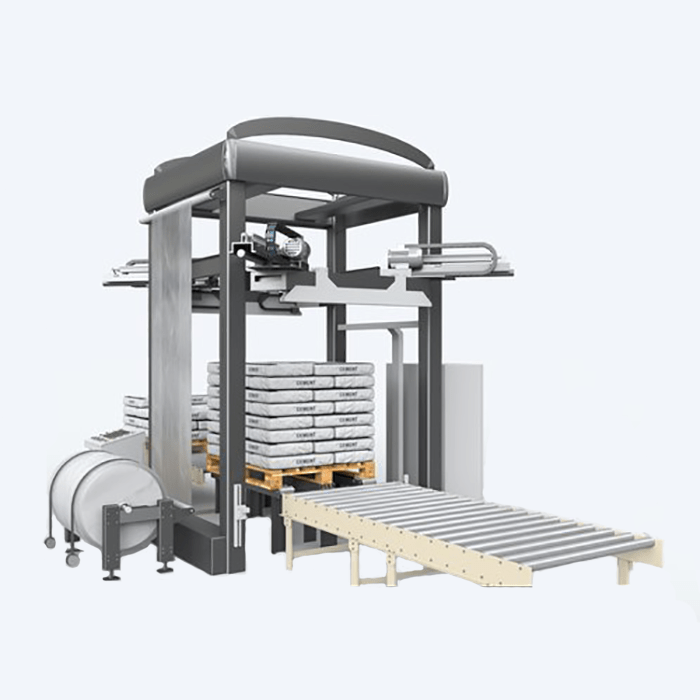

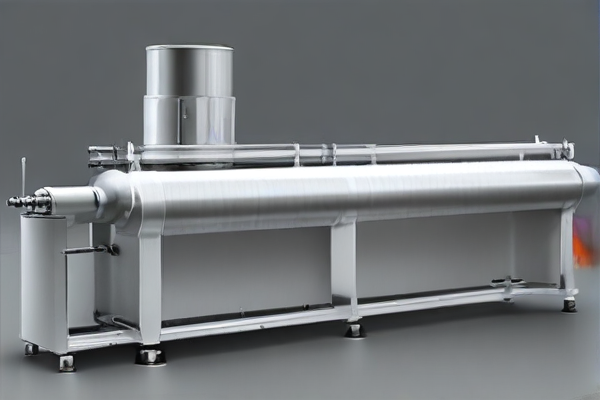

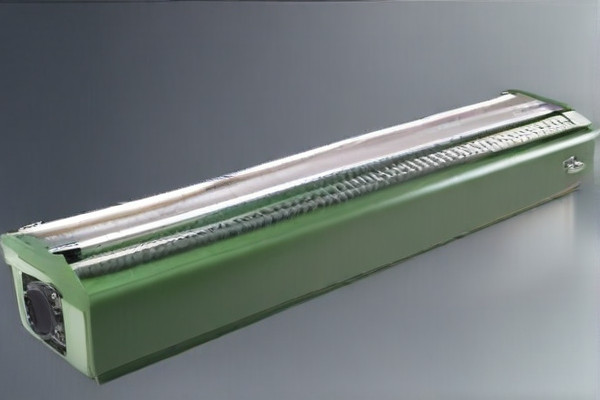

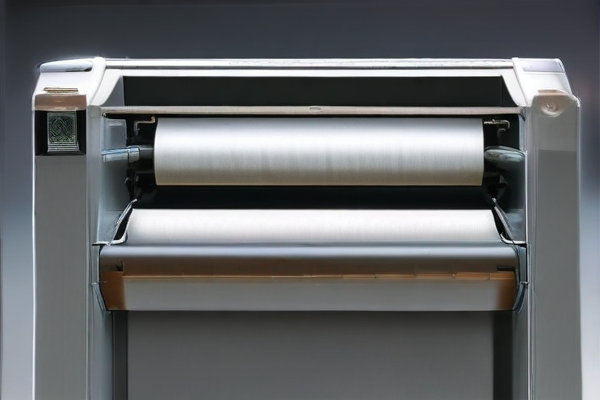

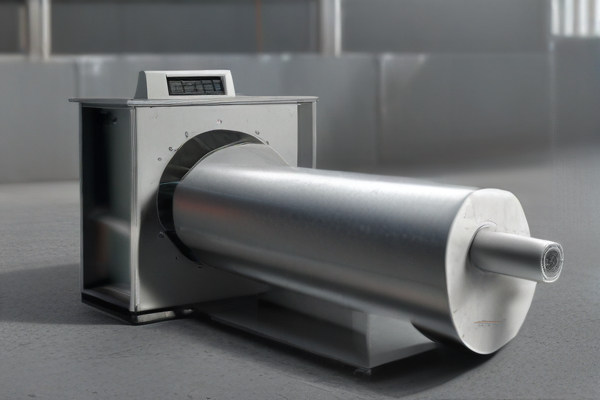

Q: What types of pre-roll machines does SourcifyChina Factory offer?

A: SourcifyChina Factory offers a variety of pre-roll machines, including small-scale tabletop models, mid-range semi-automatic machines, and fully automated industrial models designed for high-volume production.

Q: Can I customize the pre-roll machine to meet my specific requirements?

A: Yes, customization options are available. You can work with SourcifyChina Factory to tailor the machine to your specifications, such as adjusting the size or incorporating additional features.

Q: What is the lead time for manufacturing and delivery?

A: The lead time typically ranges from 4 to 6 weeks, depending on the complexity and customization of the order. Shipping time will vary based on your location.

Q: Do the machines come with a warranty?

A: Yes, SourcifyChina Factory usually provides a warranty period of 1 year, which includes parts and labor. Extended warranty options might also be available.

Q: What support is offered after purchase?

A: Post-purchase support includes installation guidance, training, and troubleshooting assistance. You can also access after-sales service for repairs and maintenance.

Q: How can I place an order?

A: Orders can be placed directly through SourcifyChina Factory’s official website or by contacting their sales team via email or phone.

Q: What payment methods are accepted?

A: Payment methods typically include bank transfers (T/T), credit cards, and sometimes PayPal. Specific terms and options should be verified with the sales team.

Q: Is it possible to visit the factory before making a purchase?

A: Yes, factory visits can be arranged. It’s a great opportunity to inspect the machines and meet the team. You’ll need to contact SourcifyChina Factory to schedule your visit.

Q: Are sample machines available for testing before purchase?

A: In some cases, sample machines can be provided for testing. You’ll need to discuss this option directly with SourcifyChina Factory.