Sure, here are some Frequently Asked Questions (FAQ) complete with answers about manufacturing pouch packaging machines with quality work from SourcifyChina factory:

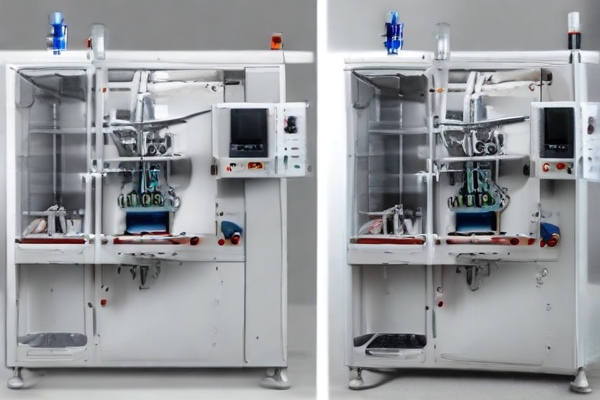

Q1: What types of pouch packaging machines do you manufacture?

A1: SourcifyChina manufactures a variety of pouch packaging machines, including stand-up pouch, zipper pouch, spout pouch, vacuum pouch, and sachet packing machines. We cater to different industries such as food, pharmaceuticals, and cosmetics.

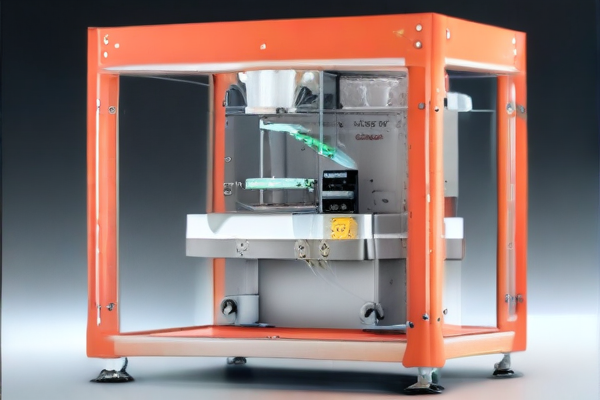

Q2: How can I ensure the quality of the pouch packaging machines from SourcifyChina?

A2: Our factory follows stringent quality control processes, from material selection to final testing. We are ISO 9001 certified and conduct multiple quality checks. We also provide certificates of compliance upon request.

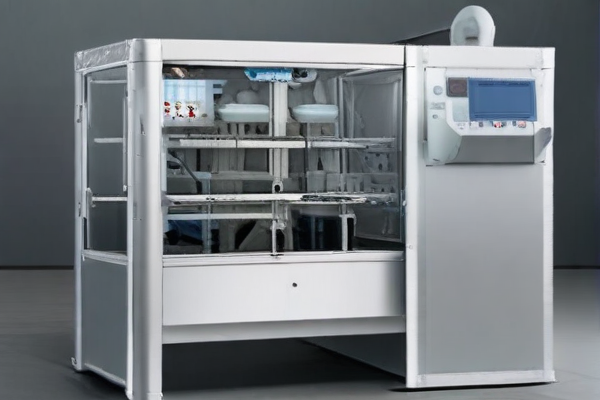

Q3: Can you customize a pouch packaging machine according to my specific needs?

A3: Yes, we offer customization services. Our engineers will work closely with you to tailor the machine to meet your specific requirements, including size, capacity, and functionality.

Q4: What is the typical lead time for manufacturing a pouch packaging machine?

A4: The standard lead time is typically 6-8 weeks, depending on the complexity of the machine and customization needs. Lead times are discussed and confirmed during the ordering process.

Q5: Do you offer after-sales support and maintenance services?

A5: Yes, we provide comprehensive after-sales support, including installation guidance, troubleshooting, and maintenance services. We also offer a warranty period and supply spare parts as needed.

Q6: How do I place an order with SourcifyChina?

A6: To place an order, contact our sales team with your requirements. After discussing details and confirming the specification, we will provide a formal quotation and an order confirmation.

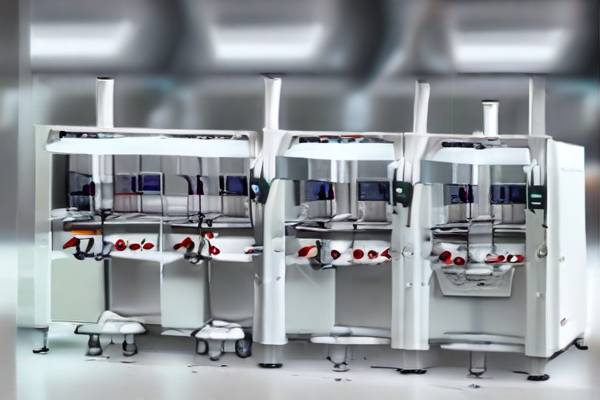

Q7: Are there minimum order quantities (MOQs) for your pouch packaging machines?

A7: We do not have strict MOQs for our machines, but pricing can be more favorable with higher quantities. Individual order discussions can clarify specific requirements.

Q8: Can I visit the SourcifyChina factory to inspect the machines before purchasing?

A8: Absolutely, we welcome you to visit our factory to inspect the machines and meet our team. Please schedule an appointment in advance to ensure a comprehensive tour.

Q9: Do you export globally?

A9: Yes, we export our packaging machines worldwide. We handle all the necessary documentation and logistics to ensure smooth delivery to your location.