1. What is the lead time for sourcing a flow packing machine from SourcifyChina factory?

The lead time typically ranges from 4 to 8 weeks, depending on the machine specifications and current order backlog.

2. What certifications do the flow packing machines from SourcifyChina factory hold?

The machines are generally certified by CE, ISO9001, and may have additional certifications based on customer requirements.

3. What is the warranty period for the flow packing machines?

SourcifyChina offers a standard warranty period of 12 months from the date of installation.

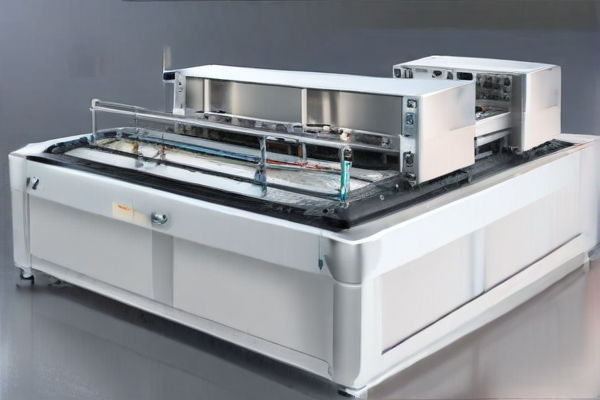

4. Are there any customization options available for the flow packing machines?

Yes, SourcifyChina provides customization options including different sizes, packing speeds, and additional features to suit specific needs.

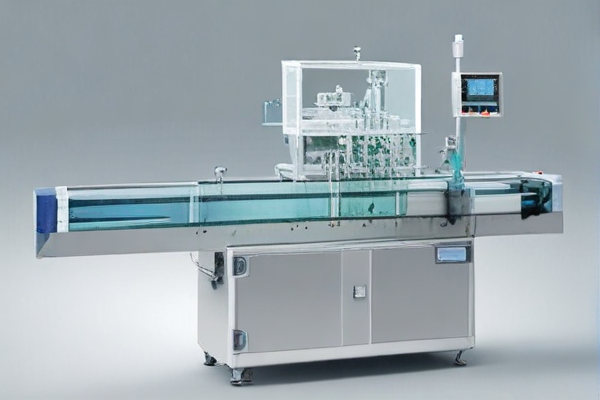

5. What after-sales services are provided?

After-sales services include remote technical support, on-site installation assistance, spare parts supply, and maintenance services.

6. Do the machines come with operation and maintenance manuals?

Yes, each machine comes with detailed operation and maintenance manuals to ensure proper usage and care.

7. Can SourcifyChina provide training for operating the flow packing machines?

Absolutely, SourcifyChina offers training sessions both onsite and online to ensure proper operation of the machines.

8. How can I get a quote for a flow packing machine?

You can get a quote by contacting the SourcifyChina sales team via their official website or email with your specific requirements.

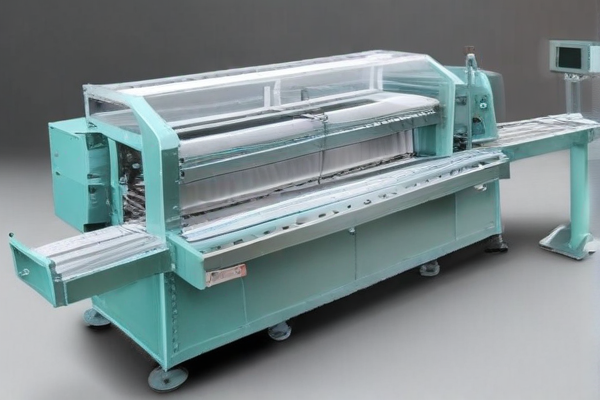

9. What types of products can be packed using these machines?

Flow packing machines from SourcifyChina can pack a wide range of products including food items, pharmaceuticals, cosmetics, and industrial goods.

10. What payment terms does SourcifyChina accept?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes PayPal for smaller orders.

11. Is shipping and handling included in the price?

Shipping and handling costs are generally not included in the base price and will be quoted separately.

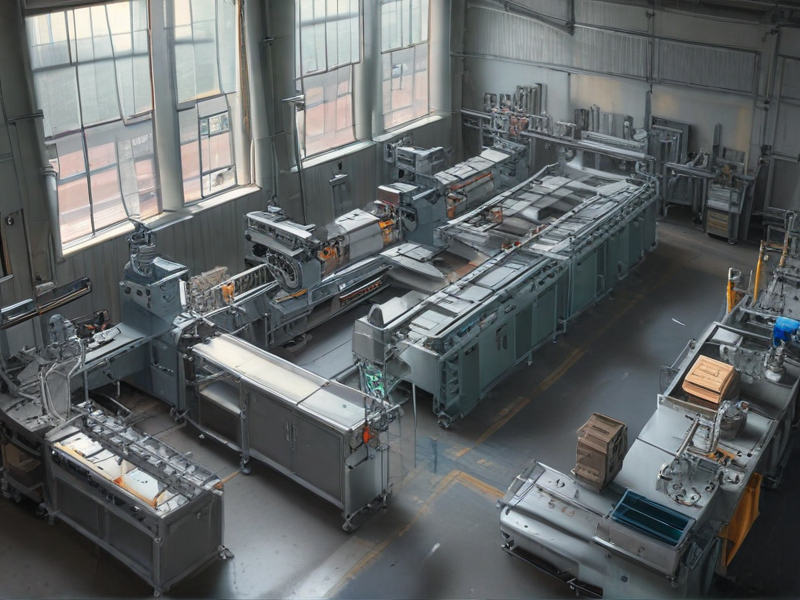

12. Can the machines be tested before shipping?

Yes, SourcifyChina welcomes customers to test the machines in their factory to ensure they meet the required specifications.