Sourcing a packaging system from SourcifyChina factory necessitates a clear plan to ensure quality and efficiency. Here are a few tips:

1. Research and Verification:

– Verify SourcifyChina’s credentials, including business licenses and certifications.

– Check their reputation through client testimonials and reviews on platforms like Alibaba, Made-in-China, or TradeKey.

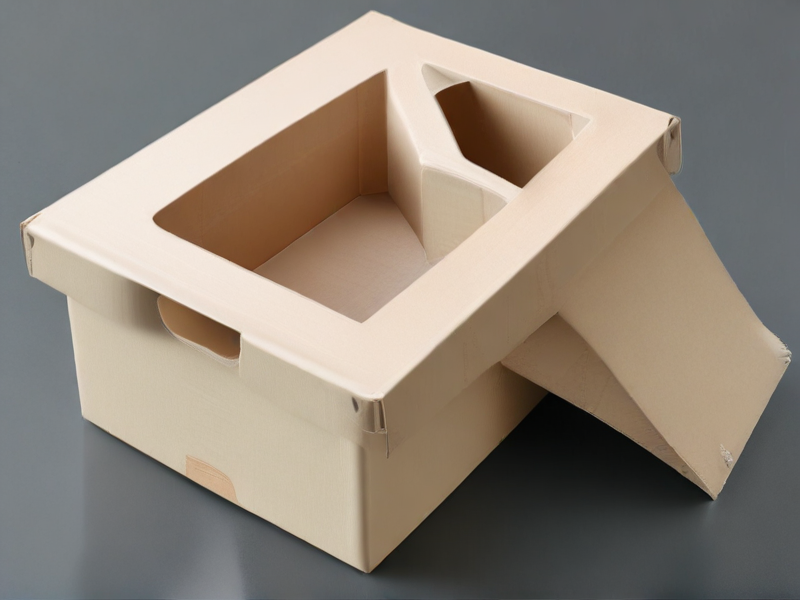

2. Detailed Requirements:

– Clearly outline your packaging requirements, including materials, designs, sizes, and quantities.

– Specify any industry standards or compliance needs, such as food safety or eco-friendly materials.

3. Request Samples:

– Ask for product samples to evaluate the quality firsthand.

– Compare samples from multiple suppliers if possible to gauge differences.

4. Communication:

– Establish clear, detailed communication channels. Use emails, video calls, and instant messaging apps to ensure continuous and transparent interaction.

– Ensure there is no language barrier; consider hiring a translator if necessary.

5. Quality Control:

– Implement a robust quality control process.

– Consider third-party inspection services in China to conduct on-site quality checks before shipment.

6. Negotiation:

– Negotiate terms of pricing, payment, and delivery.

– Aim for favorable Incoterms (e.g., FOB, CIF) to manage shipping costs effectively.

7. Contract and Agreement:

– Draft a detailed contract outlining all terms, ensuring it includes clauses on quality assurance, delivery timelines, and penalties for non-compliance.

– Get the contract reviewed by a legal professional, preferably with experience in international trade.

8. Logistics Planning:

– Plan your logistics meticulously, choosing reliable shipping partners.

– Consider framework agreements to lock in shipping rates and schedules.

By following these tips, you can streamline the process of sourcing a packaging system from SourcifyChina, ensuring quality, timeliness, and alignment with your business needs.