Sure, here are some frequently asked questions (FAQ) along with their answers regarding manufacturing inspection equipment quality work from SourcifyChina factory:

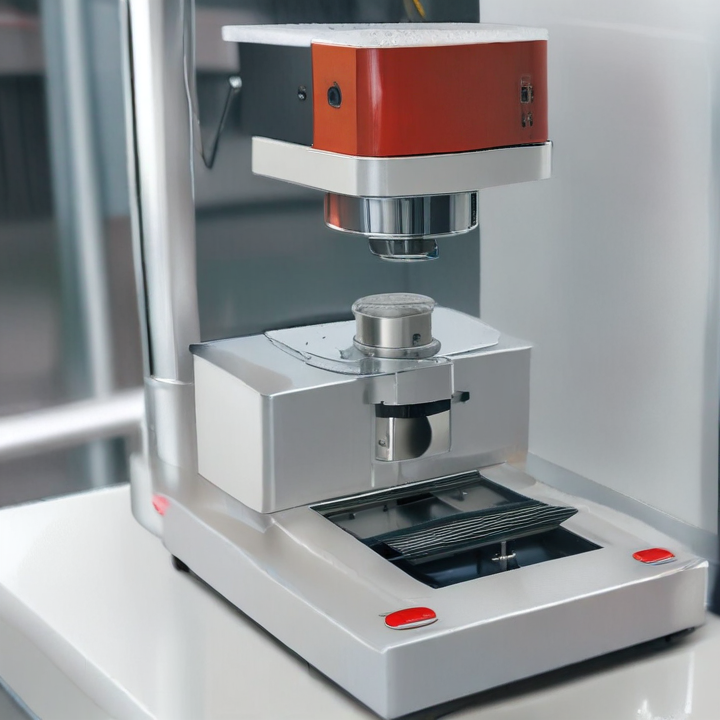

1. What types of inspection equipment does SourcifyChina manufacture?

SourcifyChina manufactures a wide range of inspection equipment including visual inspection systems, dimensional measurement tools, automated inspection machines, and non-destructive testing (NDT) equipment.

2. How does SourcifyChina ensure the quality of its inspection equipment?

SourcifyChina ensures quality by implementing rigorous quality control processes, ISO-certified production standards, and extensive testing procedures. Each piece of equipment undergoes multiple checks before shipment.

3. Can SourcifyChina customize inspection equipment to meet specific requirements?

Yes, SourcifyChina offers customization options to meet the specific needs of its clients. This includes adapting existing models and designing bespoke solutions to cater to unique industry requirements.

4. What kind of after-sales support does SourcifyChina provide?

SourcifyChina provides comprehensive after-sales support including installation services, training for operators, routine maintenance, and prompt repair services. They also offer a warranty on their equipment.

5. How long does it take to deliver the equipment once an order is placed?

Delivery times can vary depending on the complexity and customization of the equipment. Standard models typically take 4-6 weeks for delivery, while customized solutions may take longer.

6. Are there any certifications for SourcifyChina’s inspection equipment?

Yes, SourcifyChina’s inspection equipment complies with international standards and has certifications such as ISO 9001, CE, and RoHS.

7. Does SourcifyChina offer demonstrations or trials of their inspection equipment?

Yes, SourcifyChina offers product demonstrations and trial periods for clients to evaluate the performance and suitability of the equipment.

8. How can I get a quote for the inspection equipment?

You can get a quote by contacting SourcifyChina directly through their website or by reaching out to their sales team via email or phone. Provide details of your specific requirements for an accurate quote.

9. What industries does SourcifyChina serve with its inspection equipment?

SourcifyChina serves a variety of industries including automotive, aerospace, electronics, pharmaceuticals, and heavy machinery.

10. Is it possible to request a visit to SourcifyChina’s factory?