FAQ for Sourcing Automatic Wrapping Machine from SourcifyChina Factory

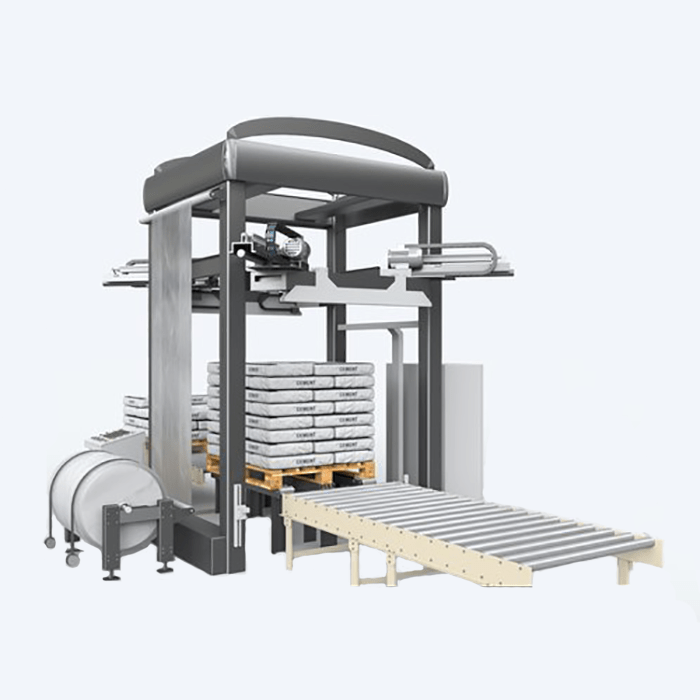

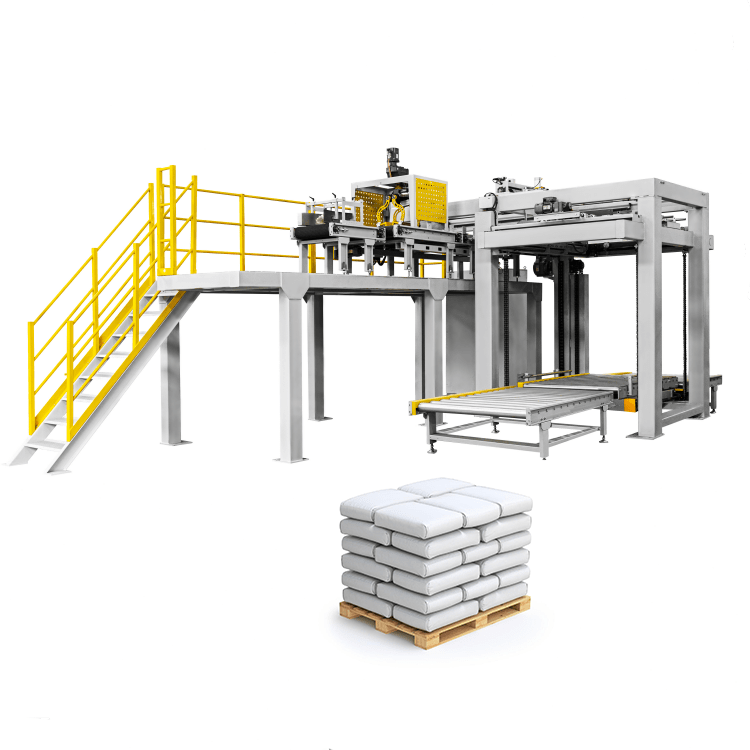

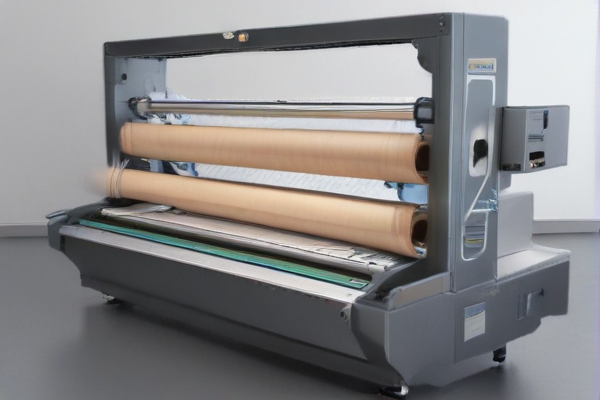

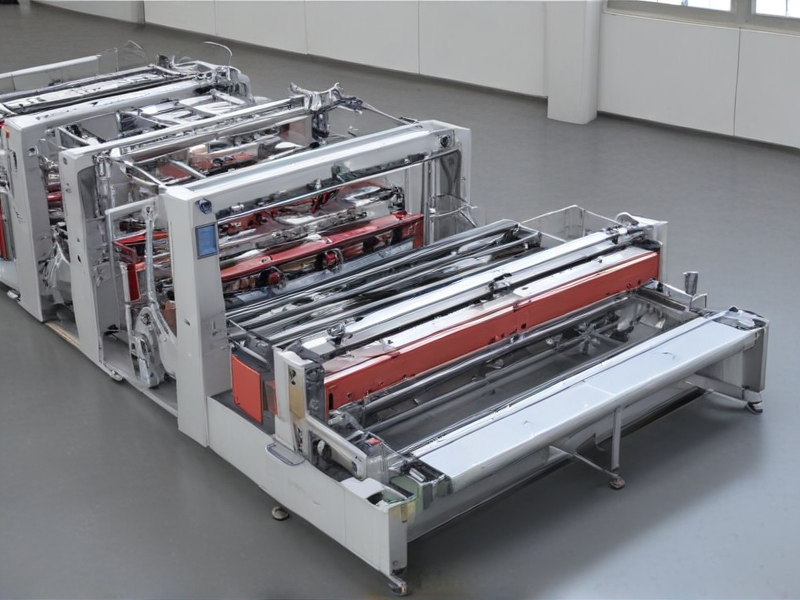

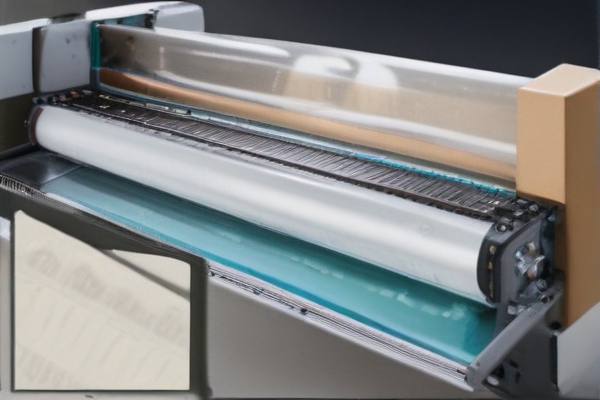

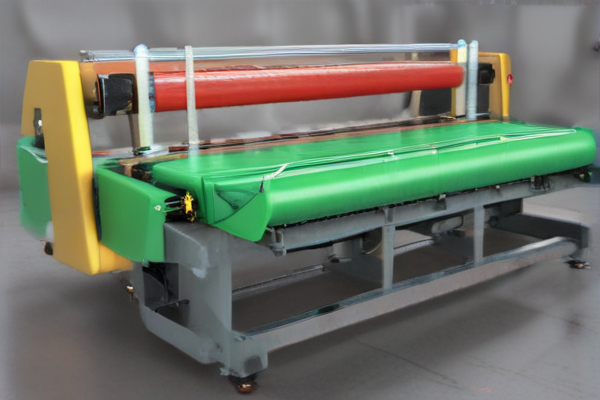

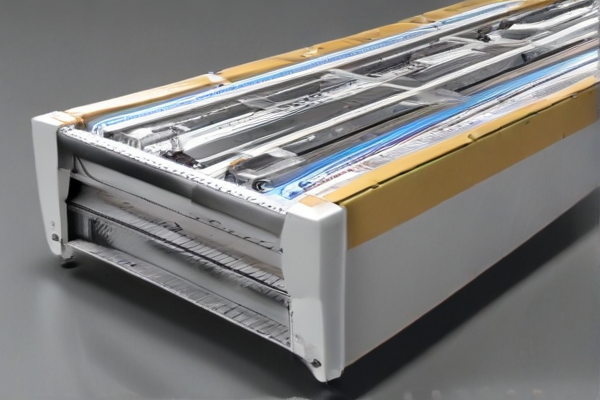

1. What is an automatic wrapping machine?

An automatic wrapping machine is a device designed to wrap products securely for packaging and shipping without the need for manual intervention. These machines boast efficiency and can handle various wrapping materials and configurations.

2. Why should I source an automatic wrapping machine from SourcifyChina factory?

SourcifyChina factory is known for its high-quality manufacturing standards, competitive pricing, and reliable customer support. They offer advanced technology and customization options to fit specific operational needs.

3. Can SourcifyChina factory customize the wrapping machine to our specifications?

Yes, SourcifyChina provides customizable solutions to meet unique specifications. You can discuss your requirements with their engineering team for tailored features and capabilities.

4. What are the payment terms when ordering from SourcifyChina factory?

Payment terms typically include a deposit before production and the balance before shipment. The exact terms can be discussed and agreed upon during the negotiation phase.

5. How long does it take to manufacture and deliver the machine?

The lead time for manufacturing and delivery depends on the complexity of the machine and current production schedules. Generally, it takes between 4-8 weeks, including shipping.

6. Are there warranties or after-sales services offered?

Yes, SourcifyChina provides warranties for their machines, along with comprehensive after-sales services such as installation guidance, technical support, and maintenance services.

7. What kind of technical support is available?

Technical support includes remote assistance via phone or email, and in some cases, on-site services. Training for your staff can also be arranged.

8. How do I get a quote for an automatic wrapping machine?

To get a quote, you can contact SourcifyChina directly through their website or via email, providing details about your requirements and any customization needs.

9. What shipping options are available?

SourcifyChina offers various shipping options, including air and sea freight. They can also handle logistics and delivery to your specified location.

10. How do I ensure the quality of the machine before purchasing?

You can request samples or visit the factory for a tour. Additionally, SourcifyChina adheres to stringent quality control measures and provides detailed product specifications and certifications.