Sure, here is a list of FAQs with answers about manufacturing liquid packing machines at SourcifyChina factory:

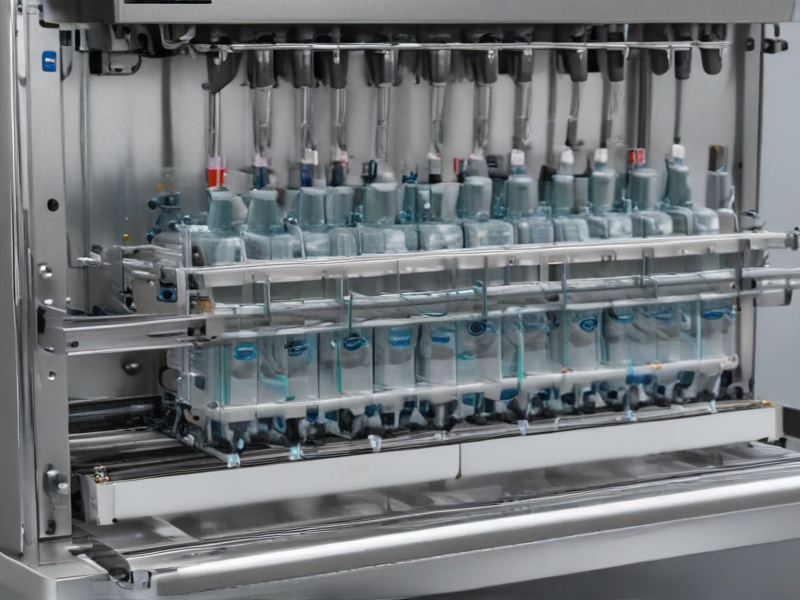

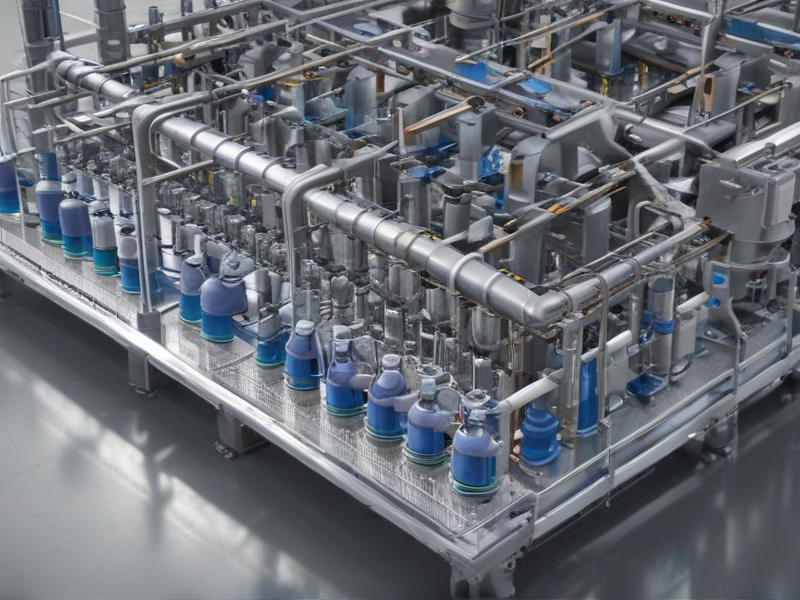

1. What types of liquid packing machines does SourcifyChina manufacture?

SourcifyChina manufactures various types of liquid packing machines including automatic, semi-automatic, and custom-designed machines suitable for different liquid viscosities and packaging requirements.

2. How can I ensure the quality of liquid packing machines from SourcifyChina?

SourcifyChina employs stringent quality control measures, including ISO certification, regular inspections, and testing each machine extensively before delivery to ensure it meets high-quality standards.

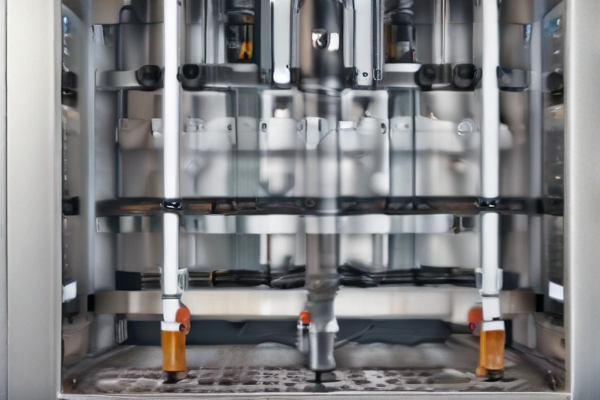

3. What materials are used in the construction of these machines?

Our liquid packing machines are built using high-grade stainless steel and other durable materials that comply with international standards for reliability and longevity.

4. Can SourcifyChina customize machines according to my requirements?

Yes, SourcifyChina offers customization services to meet specific requirements, including size, capacity, and additional functionalities, ensuring the machine perfectly fits your production needs.

5. What after-sales services does SourcifyChina provide?

We provide comprehensive after-sales services that include installation support, technical training, regular maintenance checks, and prompt resolution of any operational issues.

6. How long does it take to manufacture and deliver a liquid packing machine?

The manufacturing and delivery time can vary depending on the complexity and customization required, but typically ranges between 6 to 12 weeks.

7. What is the warranty period for SourcifyChina’s liquid packing machines?

SourcifyChina offers a standard warranty period of one year from the date of installation, covering any manufacturing defects or functional issues.

8. How energy-efficient are SourcifyChina’s liquid packing machines?

Our machines are designed to be energy-efficient, using the latest technology to minimize power consumption while maintaining high performance and efficiency.

9. Can these machines handle various types of liquids?

Yes, our machines are versatile and can handle a wide range of liquids, including water, oils, syrups, and other viscous substances.

10. How do I place an order with SourcifyChina?

You can place an order by contacting our sales team via email or phone, providing your specifications, and our team will guide you through the process from quotation to delivery.