Sure! Here are some frequently asked questions (FAQ) related to the manufacturing of auto labeling machines by SourcifyChina factory:

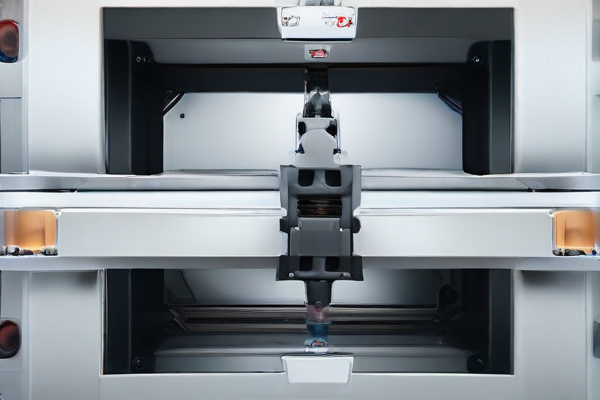

1. What types of auto labeling machines does SourcifyChina produce?

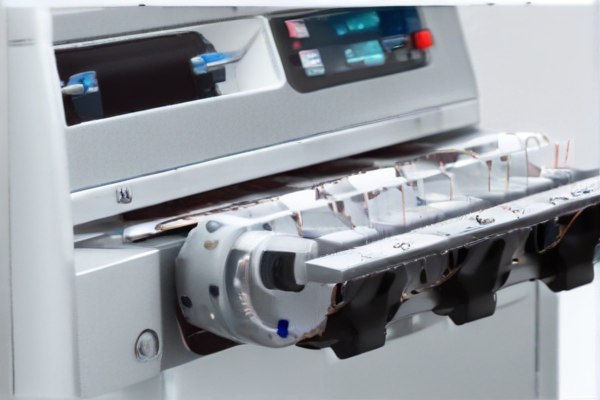

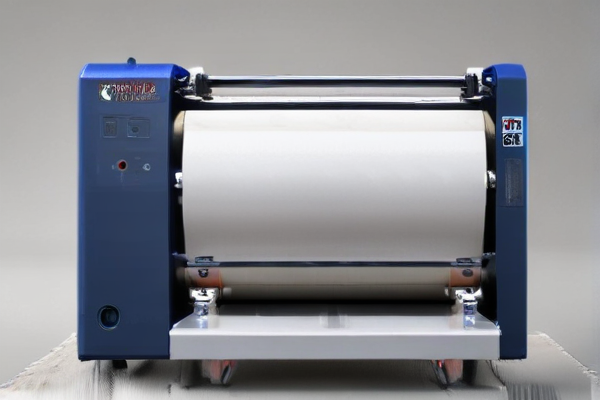

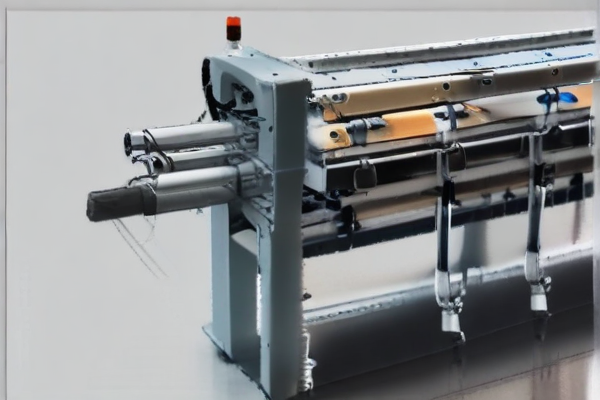

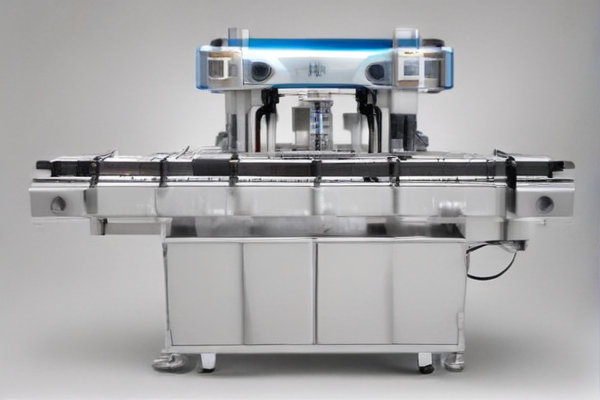

SourcifyChina manufactures a variety of auto labeling machines, including pressure-sensitive labelers, shrink sleeve labelers, and roll-fed labeling machines. Custom solutions are also available to meet specific industry requirements.

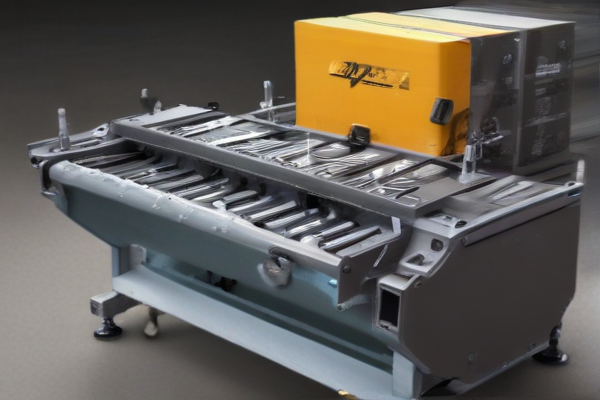

2. What materials are used in the construction of the labeling machines?

SourcifyChina utilizes high-quality stainless steel and aluminum alloy for the frame and key components of our labeling machines, ensuring durability, reliability, and resistance to corrosion.

3. Can SourcifyChina customize labeling machines based on specific requirements?

Yes, SourcifyChina offers customized labeling solutions. Our team works closely with clients to tailor the machine’s configuration to meet specific needs, whether it’s for unique label shapes, sizes, or material types.

4. How does SourcifyChina ensure the quality of its labeling machines?

Our factory follows strict quality control procedures, including ISO certification standards. Each machine undergoes rigorous testing and inspection before delivery to ensure it meets high-quality standards and performs reliably.

5. What is the lead time for manufacturing an auto labeling machine?

The lead time typically varies based on the complexity and customization of the machine. Generally, it ranges from 4 to 8 weeks. Specific timelines can be provided upon order confirmation.

6. Does SourcifyChina provide installation and training services?

Yes, we offer comprehensive installation and training services. Our skilled technicians can assist with onsite installation and provide detailed training to ensure proper operation and maintenance of the labeling machines.

7. What kind of after-sales support is available?

SourcifyChina offers robust after-sales support, including remote troubleshooting, spare parts supply, and routine maintenance services. Our technical support team is available to assist with any issues that may arise.

8. Are the labeling machines compatible with various container shapes and sizes?

Yes, our labeling machines are designed to be versatile and can handle a range of container shapes and sizes, providing flexible solutions for different production lines.

9. What are the power requirements for the auto labeling machines?

The power requirements typically depend on the specific model and customization options. Standard machines usually operate on 220V/50Hz power supply, but can be adjusted for different regions if needed.