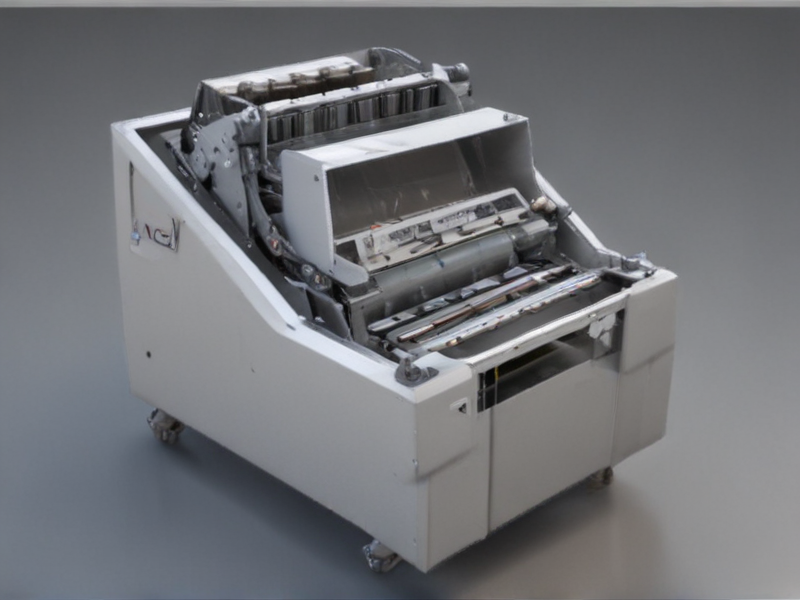

A cartoner machine packages products into cartons, ensuring safe transport and storage. Types include horizontal, vertical, and wrap-around cartoners. Options vary in speed, size, and automation levels to suit different production needs.

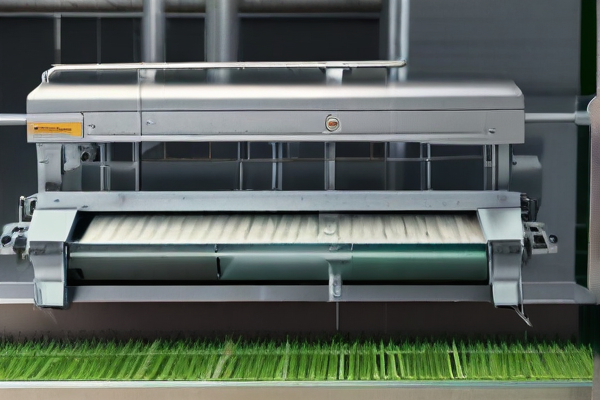

– Horizontal Cartoner: Ideal for products that can slide into cartons, such as tubes, bottles, or blister packs.

– Vertical Cartoner: Suitable for products that can be dropped into a carton from above, like bags of snacks or small components.

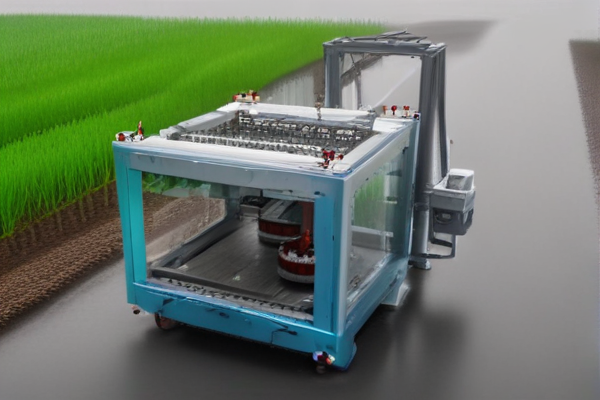

– Wrap-around Cartoner: Creates cartons around the product, ideal for irregularly shaped items.

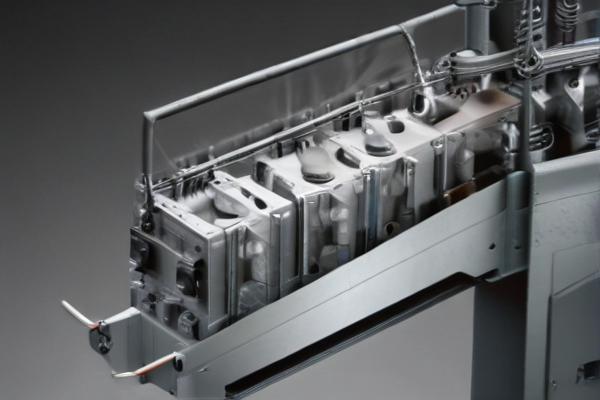

– Intermittent Motion Cartoner: Operates in a stop-start motion, suitable for low to medium-speed production lines.

– Continuous Motion Cartoner: Operates in a constant flow, designed for high-speed production requirements.

– Manual Load Cartoner: Requires human intervention to load products into the carton, suitable for small-scale operations.

– Automatic Load Cartoner: Fully automated product loading, ideal for large-scale and high-speed production.

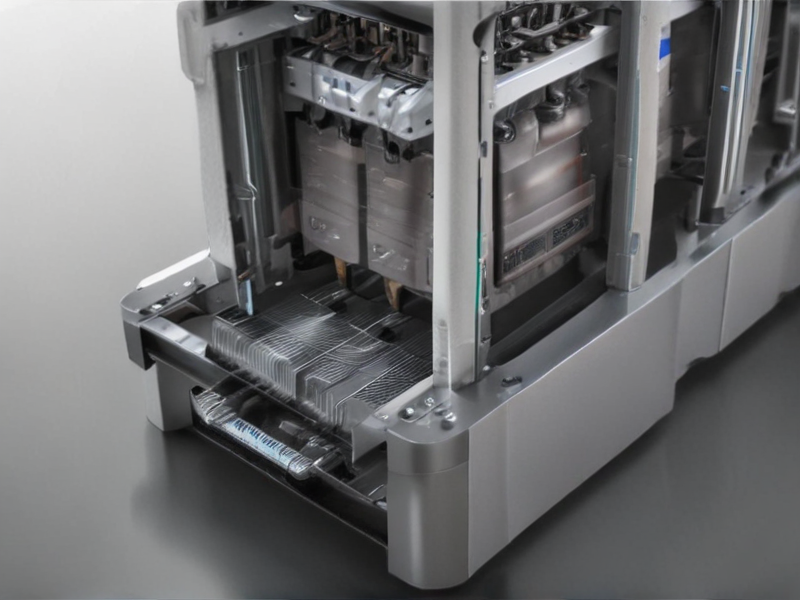

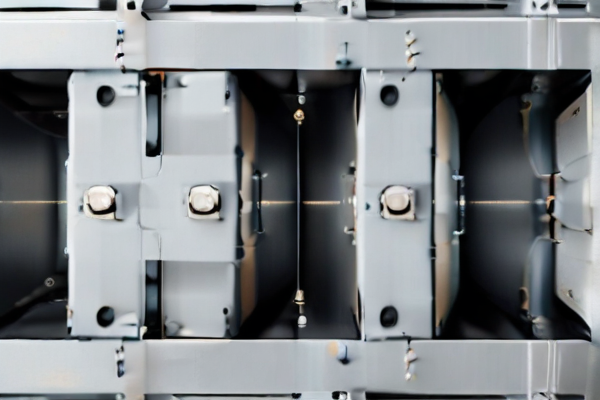

– Hot Melt Adhesive Systems: Uses hot glue for carton sealing, offering quick and strong bonds.

– Tuck-in Flap Systems: Uses mechanical tucks to close the carton flaps, eliminating the need for adhesive.

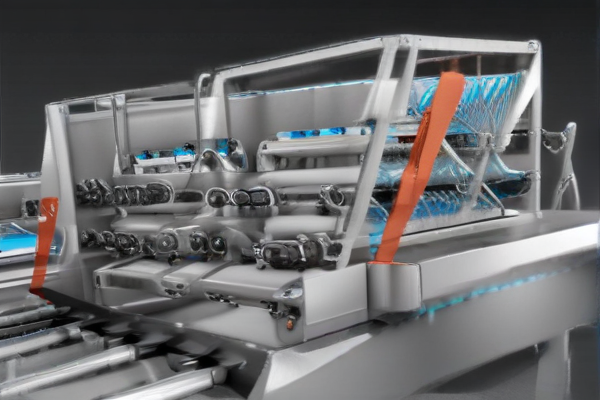

– Servo-driven Cartoner: Employs servo motors for precise and flexible control of the packaging process.

– Robotic Cartoner: Utilizes robotic arms to handle product loading, allowing for handling of delicate or diverse items.

– Variable Speed Control: Allows adjustment of cartoning speed to match production line requirements.

– User-friendly HMI (Human Machine Interface): Simplifies operator control and monitoring of the machine.

– Integration Capabilities: Easily integrates with other equipment like printers, labelers, and case packers.

– Tool-less Changeover: Facilitates easy switching between different carton sizes and products without the need for tools, reducing downtime.

Each cartoner type caters to specific packaging needs, ensuring efficiency and effectiveness in various industrial applications.