1. What types of label machines for bottles do you manufacture at SourcifyChina factory?

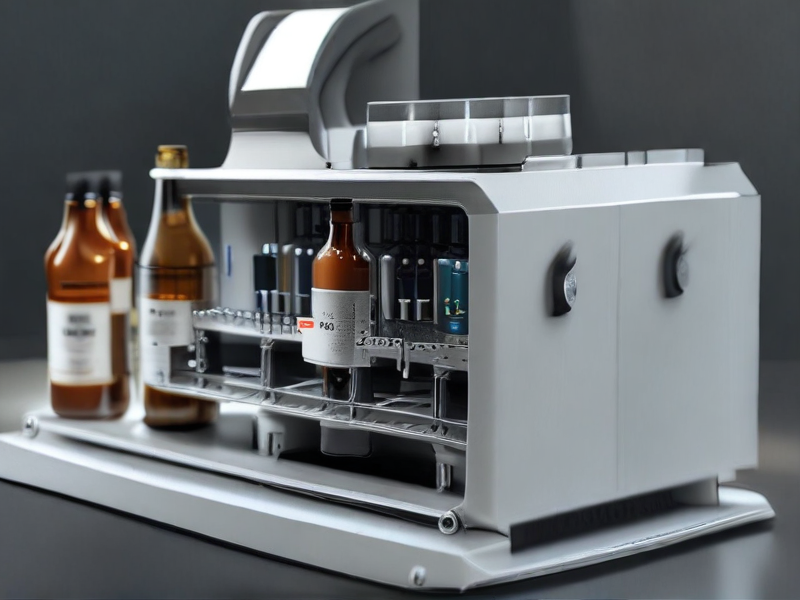

We manufacture a variety of label machines, including automatic, semi-automatic, rotary, and inline labeling machines. Our machines are designed to handle different types of bottles, such as round, square, and custom-shaped bottles.

2. What materials are used in constructing your label machines?

Our label machines are constructed using high-quality stainless steel and aluminum to ensure durability and reliability. The components are sourced from reputable suppliers to maintain high standards of quality.

3. Are your label machines compatible with different types of labels?

Yes, our machines can handle various types of labels including paper, plastic, foil, and thermal labels. They are also compatible with self-adhesive, shrink-sleeve, and wrap-around labels.

4. How do you ensure the quality of your label machines?

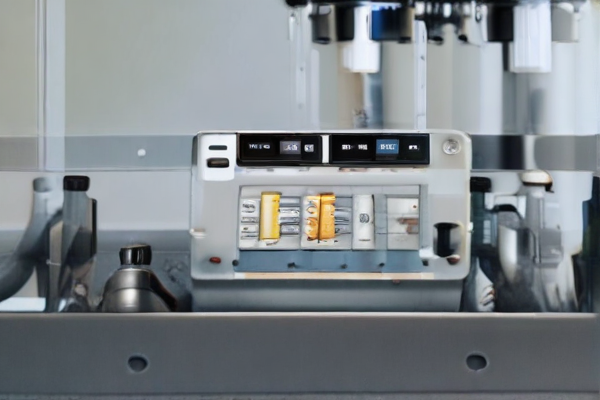

We follow strict quality control procedures, including multiple stages of inspection and testing. Each machine is tested for performance, precision, and durability before it leaves our factory.

5. What is the production capacity of your label machines?

Depending on the model, our label machines can label between 50 to 300 bottles per minute. We offer customized solutions to meet specific production requirements.

6. Do you offer after-sales support and training for your label machines?

Yes, we provide comprehensive after-sales support, including installation assistance, operator training, and ongoing technical support to ensure smooth operation of our machines.

7. Can your label machines be integrated into existing production lines?

Absolutely, our label machines are designed with flexibility in mind and can be easily integrated into existing production lines. We also offer customization services to meet specific integration needs.

8. What are your lead times for manufacturing and delivery?

Our standard lead time is typically 4 to 6 weeks, depending on the complexity and customization of the order. We strive to meet customer deadlines while maintaining high quality standards.

9. How do you handle warranty and maintenance services?

We offer a standard one-year warranty on all our machines. During this period, we provide free maintenance and replacement of defective parts. Extended warranty options are also available.

10. How can I place an order or request a quote?