Sure, here are some frequently asked questions (FAQ) with answers regarding sourcing auxiliary machines from SourcifyChina factory:

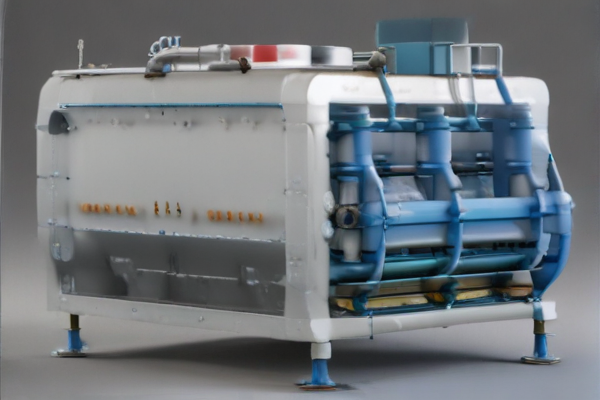

Q1: What types of auxiliary machines are available from SourcifyChina?

A1: SourcifyChina offers a wide range of auxiliary machines, including feeders, conveyors, mixers, blowers, and cooling systems, primarily geared towards manufacturing and industrial applications.

Q2: How can I request a quote for an auxiliary machine?

A2: You can request a quote by visiting the SourcifyChina website and filling out the inquiry form. Be sure to include detailed specifications and requirements to get an accurate quote.

Q3: What is the typical lead time for an order?

A3: The lead time varies depending on the machine type and quantity ordered. On average, it takes about 4-6 weeks for production and shipping. It’s best to confirm lead times during the quoting process.

Q4: Can I customize the auxiliary machines to meet my specific needs?

A4: Yes, SourcifyChina offers customization options. You can discuss your specific requirements with their engineering team to ensure the machine meets your operational needs.

Q5: What quality standards do SourcifyChina auxiliary machines adhere to?

A5: SourcifyChina adheres to international quality standards such as ISO, CE, and others relevant to the industry, ensuring high-quality and reliable products.

Q6: How does SourcifyChina handle shipping and logistics?

A6: SourcifyChina has partnerships with reputable shipping companies to manage logistics. They provide various shipping options including air, sea, and express services to meet customer preferences.

Q7: Are there any after-sales services available?

A7: Yes, SourcifyChina offers comprehensive after-sales support including installation assistance, maintenance services, and spare parts supply.

Q8: What payment methods are accepted?

A8: SourcifyChina accepts multiple payment methods including wire transfer (T/T), Letter of Credit (L/C), and other mutually agreed methods.

Q9: Can I visit the factory for an inspection?

A9: Yes, factory visits can be arranged. It’s recommended to schedule an appointment in advance to ensure availability and a guided tour.

Q10: What kind of warranty is provided?

A10: SourcifyChina typically offers a one-year warranty on their auxiliary machines, covering parts and labor for any manufacturing defects.