Sure, here is a list of FAQs with concise answers for manufacturing bottle labeling machines from SourcifyChina factory:

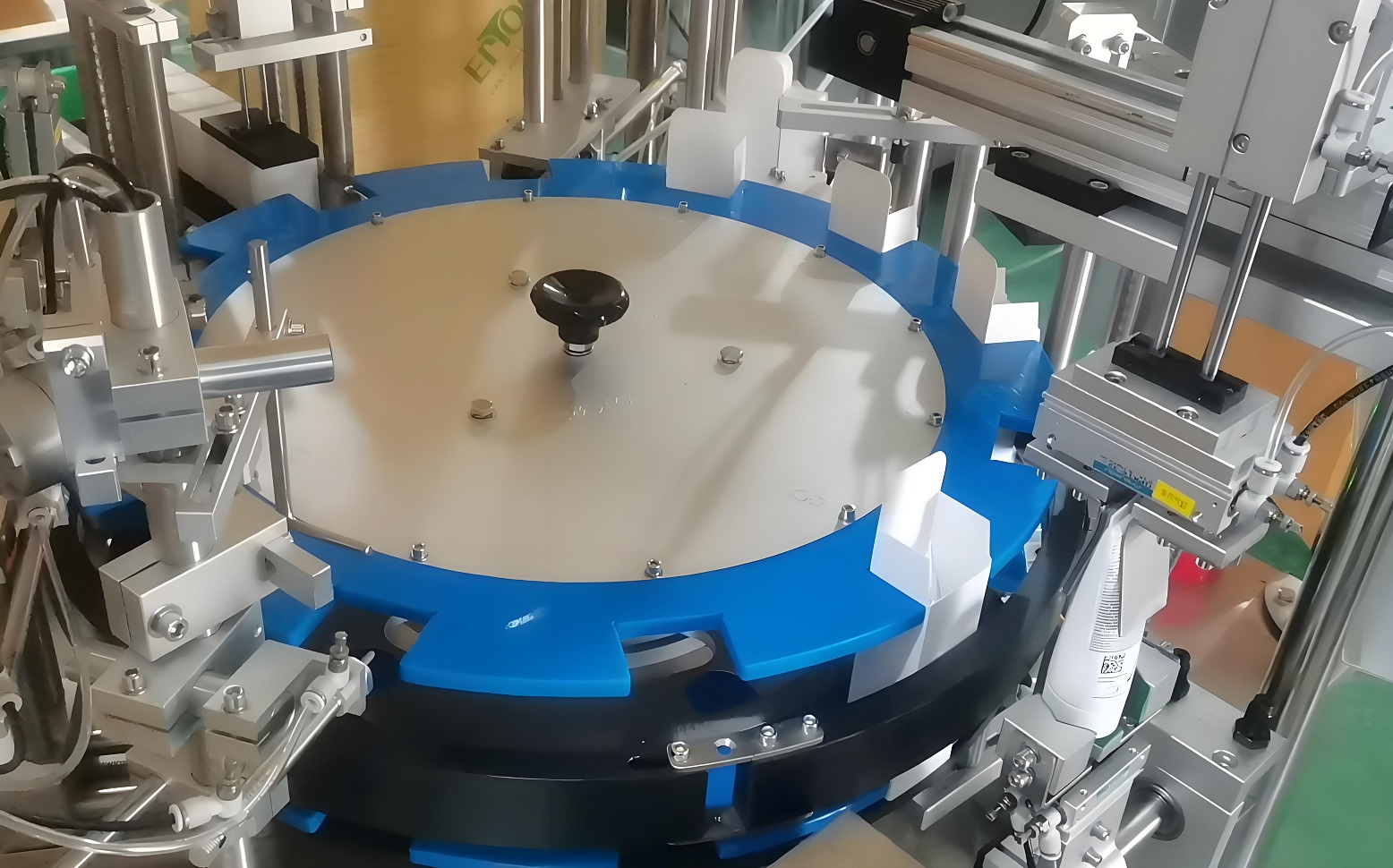

Q1: What types of bottle labeling machines does SourcifyChina factory produce?

A1: SourcifyChina factory produces various types of bottle labeling machines, including automatic, semi-automatic, and manual machines. They cater to different bottling needs such as round, square, and uniquely-shaped bottles.

Q2: What is the quality assurance process at SourcifyChina factory?

A2: The factory adheres to strict quality assurance protocols, including material inspection, in-process quality control (IPQC), final quality inspection, and performance testing to ensure all machines meet high-quality standards.

Q3: Can SourcifyChina factory customize bottle labeling machines?

A3: Yes, SourcifyChina offers customization services to tailor machines according to specific requirements such as speed, size, and labeling type to fit the unique needs of each client.

Q4: What materials are used for the construction of these machines?

A4: SourcifyChina factory uses high-grade stainless steel and aluminum alloy for durability and hygiene. All materials comply with international standards to ensure longevity and performance.

Q5: How long does it take to manufacture and deliver a bottle labeling machine?

A5: The standard manufacturing time ranges from 4-6 weeks, depending on customization requirements. Delivery time varies by destination but typically takes 1-2 weeks after manufacturing completion.

Q6: What kind of maintenance is required for these labeling machines?

A6: Regular maintenance includes cleaning, lubrication, and periodic checks for wear and tear. SourcifyChina provides detailed maintenance guides and offers after-sales support for troubleshooting and repairs.

Q7: Does SourcifyChina factory offer any warranties or guarantees?

A7: Yes, they offer a one-year warranty on all their machines, covering manufacturing defects and performance issues. Extended warranties and comprehensive service plans are also available.

Q8: Can they provide training for operating the bottle labeling machines?

A8: SourcifyChina offers comprehensive training programs, including on-site training, video tutorials, and detailed user manuals to ensure operators can use the machines efficiently and safely.

Q9: How energy-efficient are these machines?

A9: SourcifyChina factory designs their machines to be energy-efficient, incorporating advanced technology to reduce power consumption while maintaining high performance and productivity.