Sure, here are some FAQs with answers for sourcing a bottle unscrambler machine from the SourcifyChina factory:

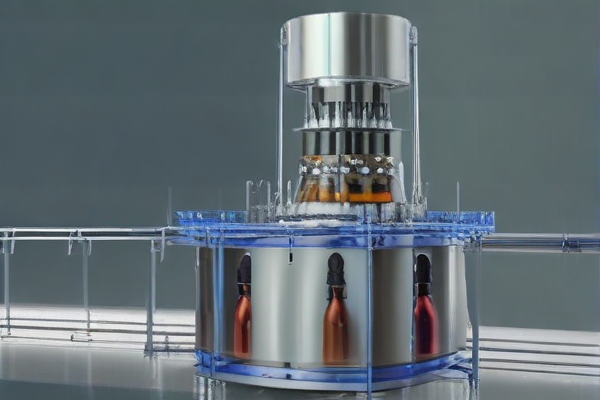

1. What is the production capacity of the bottle unscrambler machine?

The production capacity varies based on the model and specifications of the machine. Typically, SourcifyChina’s bottle unscramblers can handle between 100 to 300 bottles per minute. For exact figures, please consult the product datasheet or contact customer support.

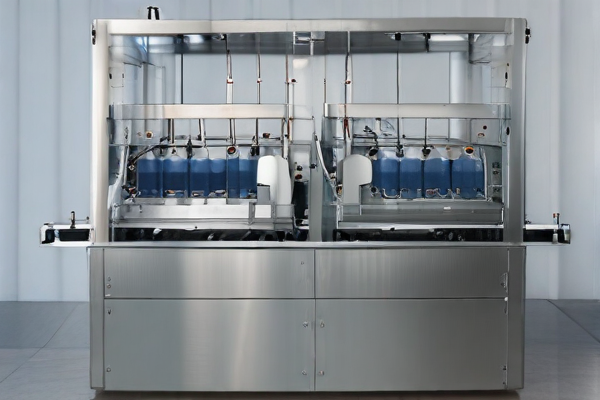

2. Can the machine handle various bottle sizes and shapes?

Yes, the bottle unscrambler machines from SourcifyChina are designed to handle a wide range of bottle sizes and shapes. The machines are versatile and can be adjusted to accommodate different dimensions and forms.

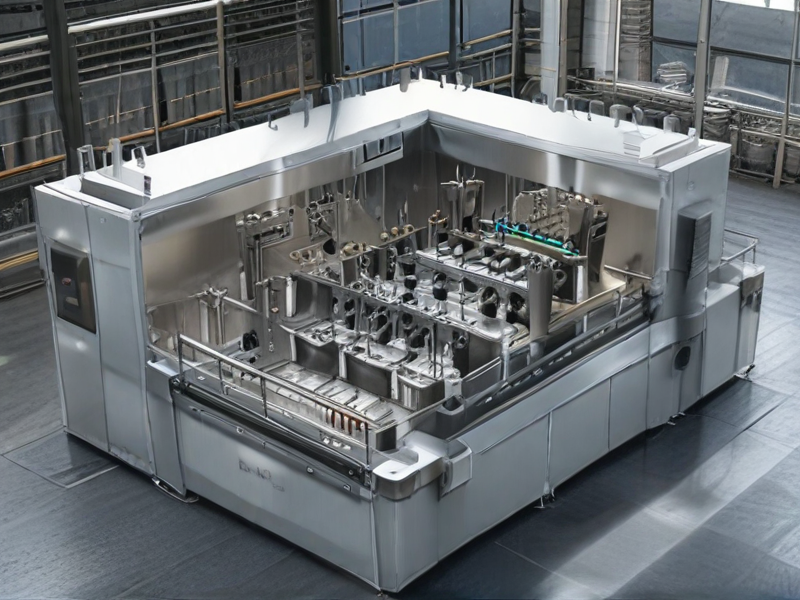

3. What materials are used in the construction of the machine?

The bottle unscrambler machines are constructed using high-quality stainless steel and food-grade materials to ensure durability, hygiene, and compliance with industry standards.

4. What are the power requirements for the bottle unscrambler machine?

The power requirements depend on the specific model of the machine. Generally, these machines operate on standard industrial power supplies, typically 220V/380V, 50Hz/60Hz. Refer to the technical specifications for detailed information.

5. Is there a warranty period for the machine?

Yes, SourcifyChina offers a warranty period for their bottle unscrambler machines. The standard warranty period is usually one year from the date of installation. Extended warranty options may also be available.

6. Do you provide after-sales service and support?

Absolutely! SourcifyChina provides comprehensive after-sales service, including installation, training, troubleshooting, and maintenance support. Their technical team is available to assist you as needed.

7. What is the lead time for delivery after placing an order?

The lead time for delivery depends on the order size and customization requirements. Typically, it takes about 4 to 6 weeks for production and delivery. For specific timelines, please contact the sales team.

8. How can I request a quote or place an order?

You can request a quote or place an order by contacting SourcifyChina through their official website, email, or phone. Provide the necessary details about your requirements to get an accurate quote.

9. Are there options for customization?