Sure, here are some FAQs about manufacturing an auto filling machine with quality work from SourcifyChina factory:

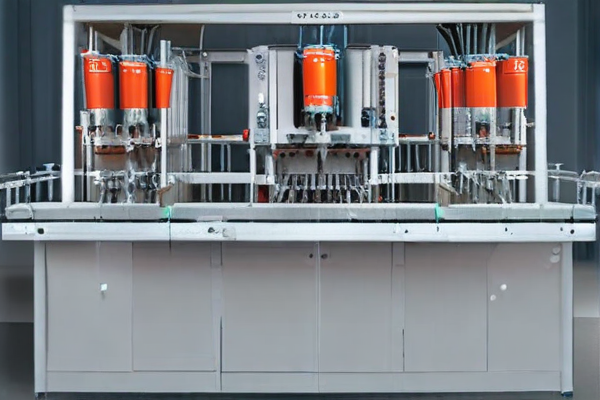

1. What types of filling machines does SourcifyChina manufacture?

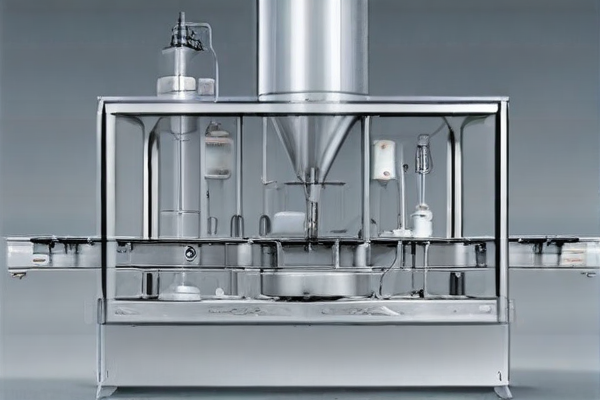

SourcifyChina manufactures a variety of filling machines including liquid filling machines, powder filling machines, paste filling machines, and granular filling machines to meet different industry requirements.

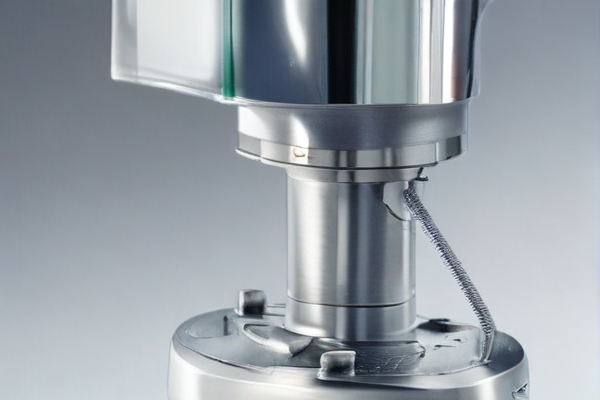

2. What materials are used in the construction of your filling machines?

Our filling machines are constructed from high-grade stainless steel to ensure durability, hygiene, and compliance with industry standards such as ISO and CE certifications.

3. Can the filling machine be customized according to specific needs?

Yes, SourcifyChina offers customization options to tailor the filling machines to specific product requirements, including varying filling speeds, container sizes, and types of products being filled.

4. What is the lead time for manufacturing and delivery?

The lead time for manufacturing depends on the complexity and customization requirements of the order. Typically, it ranges from 4 to 8 weeks. Delivery time varies based on the shipping method and destination.

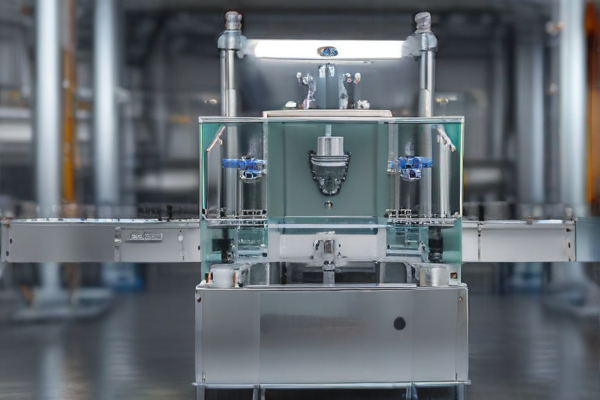

5. What kind of quality control measures are in place at SourcifyChina?

SourcifyChina employs rigorous quality control measures, including material inspection, in-process checks, and final testing under real operating conditions to ensure each machine meets high-quality standards before shipment.

6. Is technical support and after-sales service available?

Yes, SourcifyChina provides comprehensive technical support and after-sales service. This includes installation assistance, operational training, and ongoing maintenance support to ensure optimal machine performance.

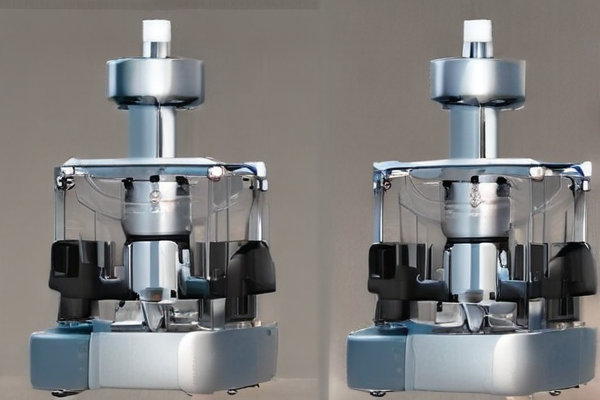

7. How energy-efficient are the filling machines?

Our filling machines are designed with energy efficiency in mind. They incorporate advanced control systems to minimize power consumption while maintaining high productivity and accuracy.

8. Can SourcifyChina supply spare parts for their filling machines?

Yes, we stock a wide range of spare parts and offer expedited shipping to ensure minimal downtime for your operations.

9. How do I get a quote or place an order?

You can contact us directly via our website or customer service email. Provide your specific requirements, and we will offer a detailed quotation and guide you through the ordering process.

10. Do you offer any warranty on your filling machines?

Yes, SourcifyChina offers a limited warranty covering parts and labor for a specific period, ensuring peace of mind and reliability for your investment. Terms and conditions apply.