Sure, here is a list of FAQs with answers for sourcing syrup filling machines from SourcifyChina Factory:

1. What types of syrup filling machines does SourcifyChina offer?

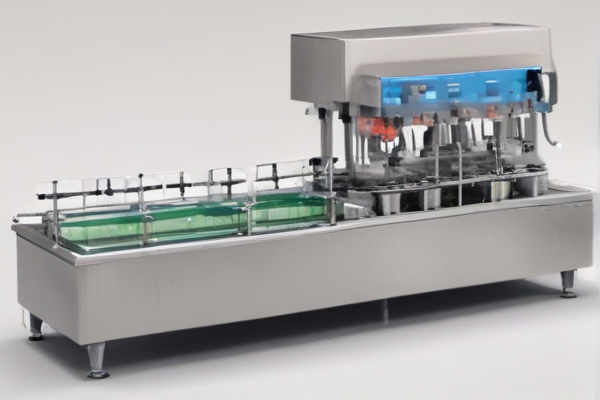

SourcifyChina provides a range of syrup filling machines, including automatic, semi-automatic, and manual models. These machines are suitable for various bottle sizes and production capacities.

2. Can SourcifyChina customize syrup filling machines based on my requirements?

Yes, SourcifyChina offers customization options to meet specific needs, including adjusting nozzle sizes, conveyor systems, and integrating with existing production lines.

3. What is the lead time for manufacturing and delivering a syrup filling machine?

The lead time usually ranges from 4 to 6 weeks, depending on the complexity and customization requirements. Shipping time will vary based on the destination.

4. Is there a minimum order quantity (MOQ) for syrup filling machines from SourcifyChina?

Generally, the MOQ for syrup filling machines is one unit, making it accessible for small-scale operations as well as large manufacturers.

5. What kind of technical support and after-sales service does SourcifyChina provide?

SourcifyChina offers comprehensive technical support, including installation assistance, user manuals, and troubleshooting guides. After-sales service includes routine maintenance checks and availability of spare parts.

6. How does SourcifyChina ensure the quality of its syrup filling machines?

SourcifyChina adheres to stringent quality control processes, including rigorous testing and compliance with international standards (ISO, CE). Each machine is thoroughly inspected before shipment.

7. What payment methods are accepted by SourcifyChina?

SourcifyChina accepts various payment methods, including T/T (bank transfer), PayPal, and L/C (Letter of Credit). Specific terms can be discussed directly with their sales team.

8. How can I get a quotation for a syrup filling machine from SourcifyChina?

You can request a quotation by visiting SourcifyChina’s official website and filling out the inquiry form, or by contacting their sales team directly via email or phone.

9. Are there any warranties offered on syrup filling machines?

Yes, SourcifyChina typically provides a one-year warranty on their syrup filling machines, covering parts and labor. Extended warranties may be available upon request.

10. Can I see a demonstration or trial run of the syrup filling machine before purchasing?

SourcifyChina offers virtual demonstrations via video call or recorded video.