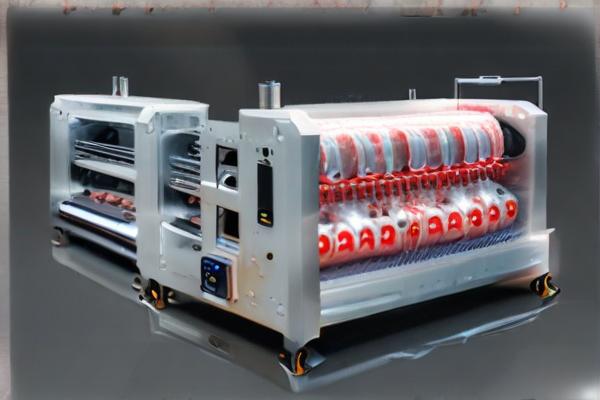

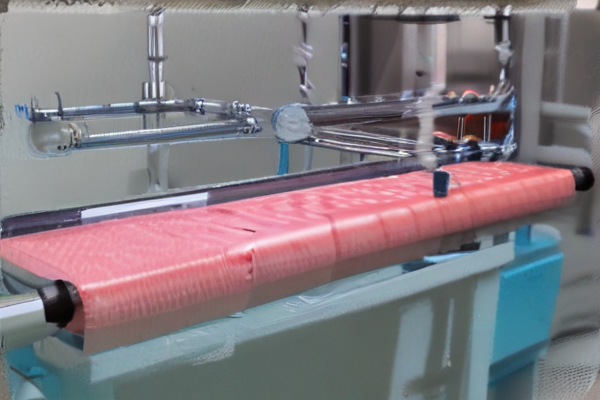

When considering candy wrap machine manufacturing from SourcifyChina factory, here are some valuable tips to keep in mind:

1. Research and Reputation:

– Investigate SourcifyChina’s market reputation by checking online reviews and industry forums.

– Request references or case studies of successful projects to ensure reliability.

2. Customization and Specifications:

– Clearly communicate your specific requirements for the candy wrap machine.

– Verify that SourcifyChina offers customization to meet your unique needs and product specifications.

3. Technology and Innovation:

– Ensure that the factory utilizes the latest technology in manufacturing to guarantee efficiency and quality.

– Inquire about advancements in machine automation, material usage, and energy efficiency.

4. Quality Standards and Certifications:

– Check if SourcifyChina adheres to international quality standards (ISO, CE, etc.).

– Request information about their quality control processes to ensure consistent product quality.

5. Cost and Value:

– Obtain detailed quotes and compare them with other manufacturers to ensure competitive pricing.

– Evaluate the overall value, considering factors like machine durability, maintenance, and operational costs.

6. After-Sales Service and Support:

– Confirm the availability of comprehensive after-sales service, including maintenance, repairs, and technical support.

– Ensure that they offer training for operating the machine efficiently.

7. Lead Time and Delivery:

– Discuss estimated lead times and ensure they align with your project timelines.

– Clarify shipping and delivery terms to avoid any delays.

8. Payment Terms:

– Understand the payment structure, including any advance payments, milestones, and final settlement.

– Consider the risks and benefits of different payment methods.

9. Communication:

– Ensure clear and continuous communication channels with the factory for updates and feedback throughout the manufacturing process.

– Designate a reliable contact person to maintain consistent communication.

By keeping these tips in mind, you can ensure a smooth process when working with SourcifyChina for your candy wrapping machine needs.