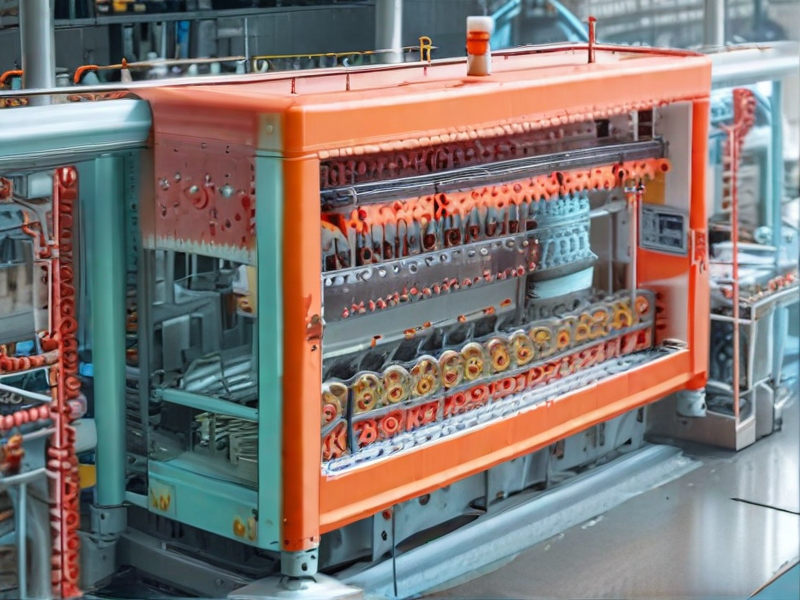

Q: What types of candy wrapping machines does SourcifyChina offer?

A: SourcifyChina provides various types of candy wrapping machines, including twist wrappers, fold wrappers, and flow wrappers to accommodate different wrapping styles and candy shapes.

Q: How can I place an order for a candy wrapping machine from SourcifyChina?

A: To place an order, visit SourcifyChina’s website and fill out the contact form, or directly email their sales team with your requirements. You can also call their customer service for immediate assistance.

Q: What information do I need to provide when inquiring about a candy wrapping machine?

A: Be ready to provide details about the type of candy to be wrapped, production capacity, preferred wrapping style, and any specific features you need.

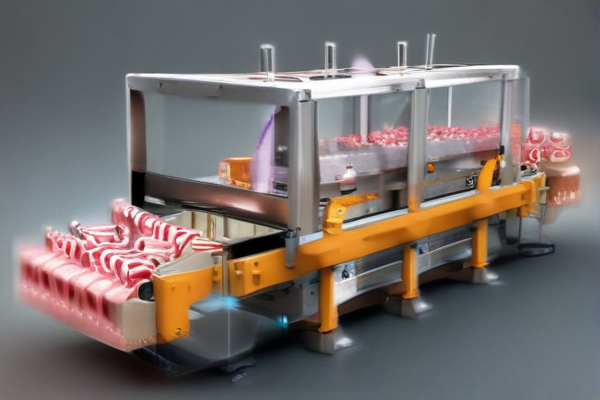

Q: Is customization available for the candy wrapping machines?

A: Yes, SourcifyChina offers customization options to tailor the machines to meet your specific production needs. This includes size adjustments, speed modifications, and additional functionalities.

Q: How long does it take to receive a candy wrapping machine after placing an order?

A: The delivery time varies depending on the machine specifications and customization requirements. Typically, it takes between 4 to 8 weeks from order confirmation to delivery.

Q: Does SourcifyChina offer international shipping?

A: Yes, they provide international shipping. Shipping costs and delivery times will vary based on the destination.

Q: What is the warranty period for the candy wrapping machines?

A: SourcifyChina offers a standard warranty period of one year for their candy wrapping machines, covering parts and labor.

Q: Are there any after-sales support services provided?

A: Yes, SourcifyChina offers comprehensive after-sales support, including machine installation assistance, operator training, and technical support via phone or email.

Q: Can I get spare parts for my candy wrapping machine from SourcifyChina?

A: Absolutely. SourcifyChina stocks a wide range of spare parts and can ship them to you as needed to ensure minimal downtime.

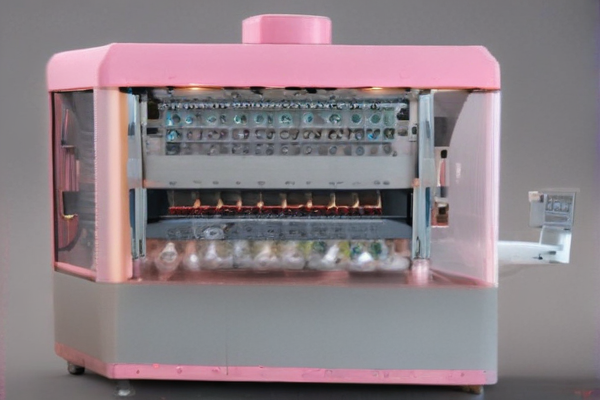

Q: How can I be sure of the quality of the candy wrapping machine?

A: SourcifyChina adheres to strict quality control standards. They also provide machine demonstrations and reference clients who can vouch for the quality and performance of their machines.