Sure, here are some frequently asked questions (FAQ) with answers about manufacturing “pouch machines quality work from SourcifyChina factory”:

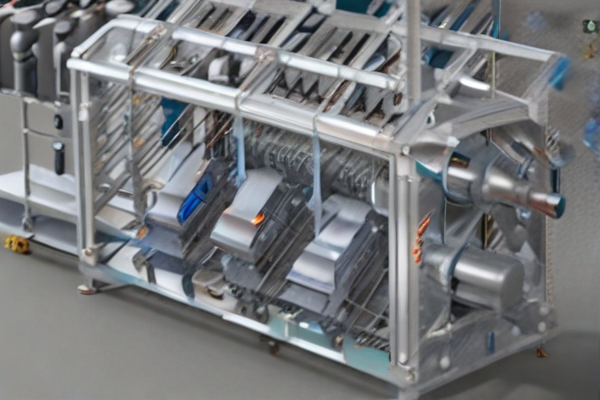

Q1: What types of pouch machines does SourcifyChina factory manufacture?

A1: SourcifyChina factory specializes in manufacturing a wide range of pouch machines, including stand-up pouch machines, flat pouch machines, zipper pouch machines, and more, tailored to meet various packaging needs.

Q2: How does SourcifyChina ensure the quality of their pouch machines?

A2: SourcifyChina adheres to stringent quality control protocols at every production stage. This includes using high-grade materials, conducting regular inspections, and integrating advanced technology and automation for consistent machine performance.

Q3: What are the typical lead times for manufacturing pouch machines at SourcifyChina?

A3: The typical lead time for manufacturing is about 8-12 weeks, depending on the complexity and customization requirements of the pouch machines. However, lead times may vary during peak production periods.

Q4: Are the pouch machines energy-efficient?

A4: Yes, SourcifyChina designs their pouch machines to be energy-efficient. They incorporate modern energy-saving technologies to reduce operational costs and lower environmental impact.

Q5: Can I customize the pouch machines to suit my specific needs?

A5: Absolutely. SourcifyChina offers customization services to tailor the pouch machines according to your specifications, including size, functionality, and additional features specific to your industry requirements.

Q6: What kind of support and maintenance services does SourcifyChina provide?

A6: SourcifyChina provides comprehensive support, including installation assistance, training, and ongoing maintenance services. They also offer prompt technical support to address any operational issues.

Q7: Is there a warranty on the pouch machines from SourcifyChina?

A7: Yes, SourcifyChina offers a warranty on all their pouch machines, typically ranging from 12 to 24 months, covering any defects in materials or workmanship.

Q8: How does SourcifyChina ensure timely delivery?

A8: SourcifyChina ensures timely delivery by maintaining effective production schedules, efficient logistics management, and strong partnerships with reliable shipping providers.

Q9: Do SourcifyChina’s pouch machines comply with international standards?

A9: Yes, all pouch machines manufactured by SourcifyChina comply with international standards, including CE and ISO certifications, ensuring safety, reliability, and quality.