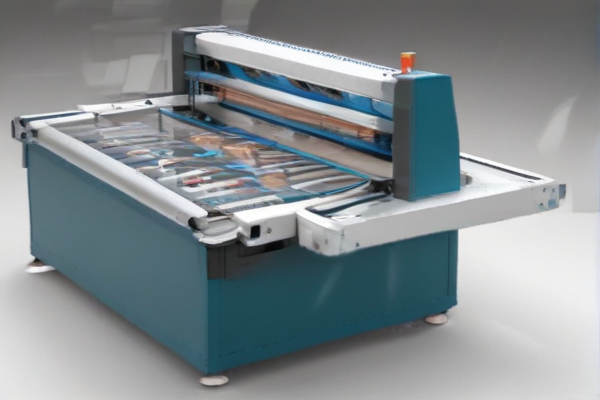

A horizontal wrapping machine is used primarily for packaging products horizontally, ensuring efficiency and consistency. These machines are widely used in various industries, offering different types such as flow wrappers, stretch wrappers, and shrink wrappers, each tailored for specific packaging needs.

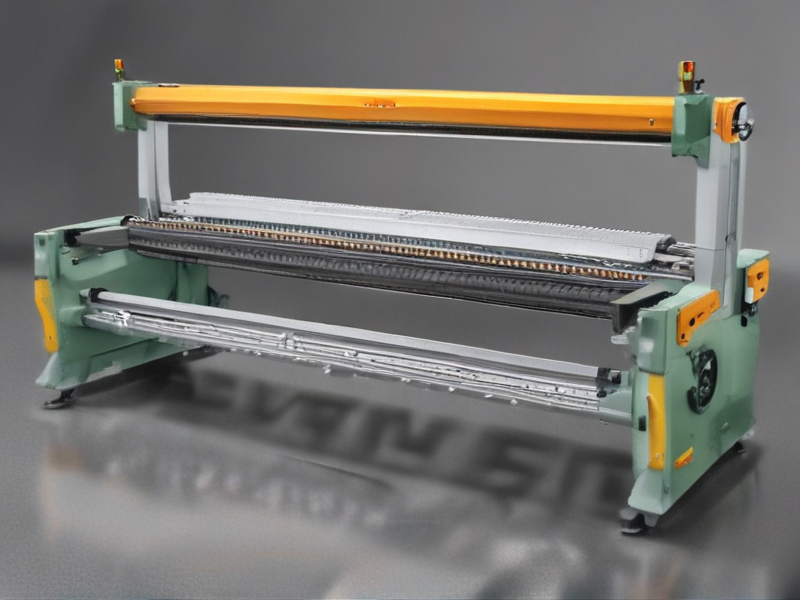

– Flow Wrappers:

– Uses: Ideal for packaging food items, confectioneries, hardware, and consumer goods.

– Material: Polypropylene (PP), polyethylene (PE), cellophane.

– Features: High-speed options, customizable configurations, and ability to handle various shapes and sizes.

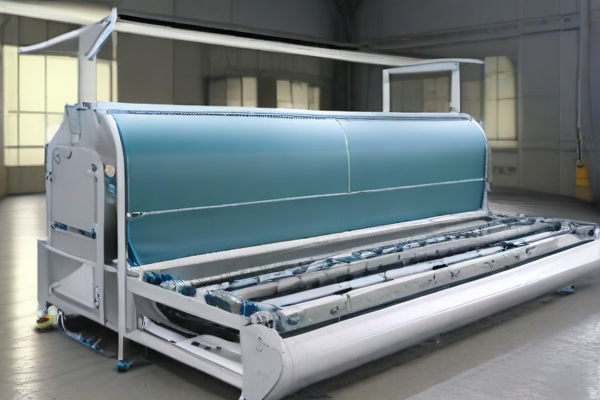

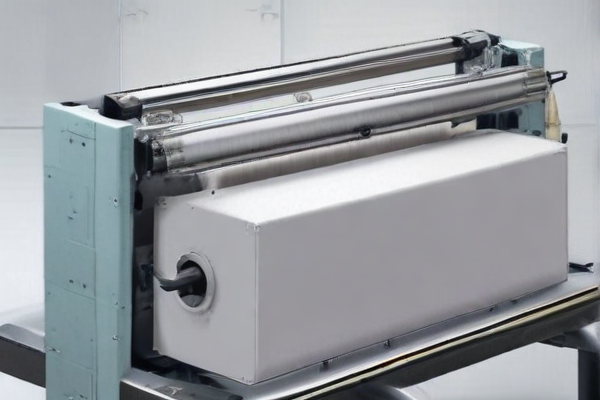

– Stretch Wrappers:

– Uses: Suitable for securing loads on pallets, bundling items together.

– Material: Stretch film.

– Features: Adjustable film tension, automatic and semi-automatic models, and pre-stretch capabilities.

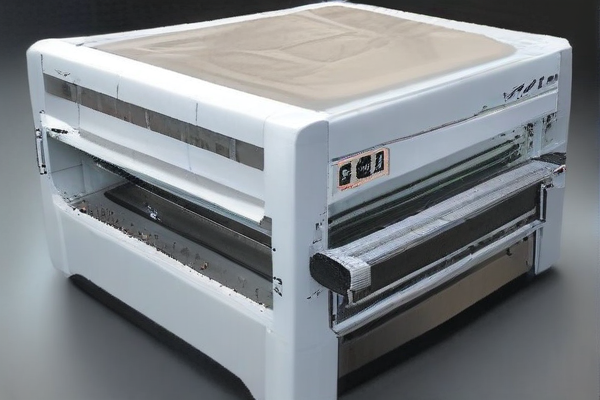

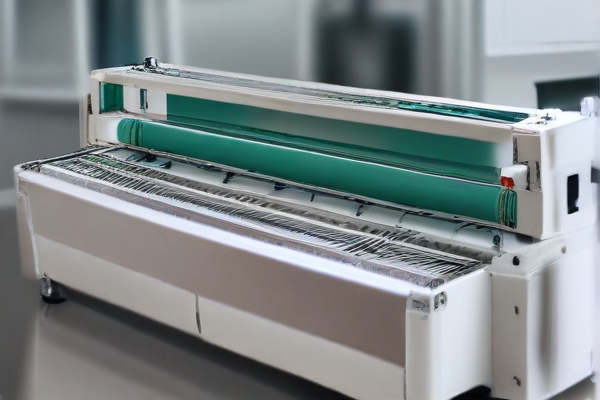

– Shrink Wrappers:

– Uses: Commonly used for packaging beverages, pharmaceuticals, and printed materials.

– Material: Polyolefin, PVC, and polyethylene shrink film.

– Features: Tunnel heat systems, uniform shrinkage, and energy-efficient options.

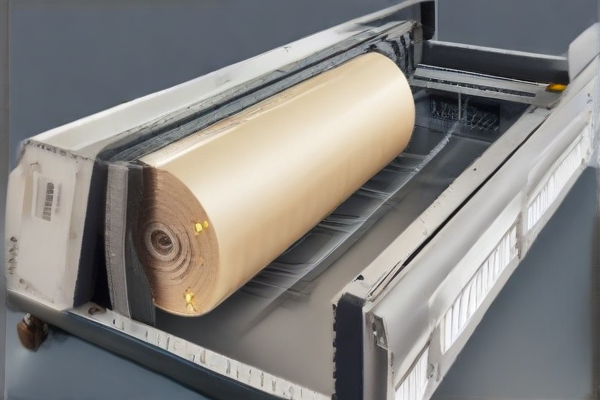

– Sleeve Wrappers:

– Uses: Ideal for packaging bulk products like bottles, cans, and boxes.

– Material: Polyethylene film.

– Features: Continuous motion operation, automatic film feeding, and minimal waste design.

– Horizontal Form-Fill-Seal (HFFS) Machines:

– Uses: For forming, filling, and sealing products in bags or pouches, used in the food and pharmaceutical industries.

– Material: Flexible films.

– Features: Integrated printing and labeling, precision filling systems, and multi-lane capabilities.

– Robotic Wrappers:

– Uses: High-speed, automated packaging suitable for complex products and high-mix, low-volume production.

– Material: Various, depending on the product.

– Features: Versatile, programmable paths, and high accuracy.

These machines offer a range of customization options based on packaging needs, speed requirements, material compatibility, and budget constraints, making them versatile tools in the manufacturing and packaging sectors.