Sure, here is a list of FAQ with answers for manufacturing a “joint packing machine quality work from SourcifyChina factory”:

1. What types of joint packing machines are available from SourcifyChina factory?

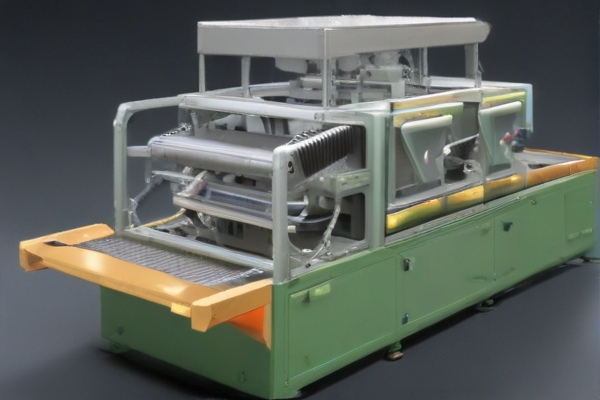

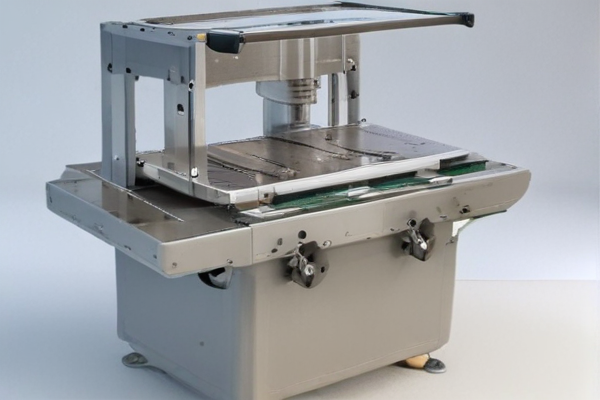

SourcifyChina factory offers various types of joint packing machines, including manual, semi-automatic, and fully automatic models, each designed to meet different production needs and efficiency requirements.

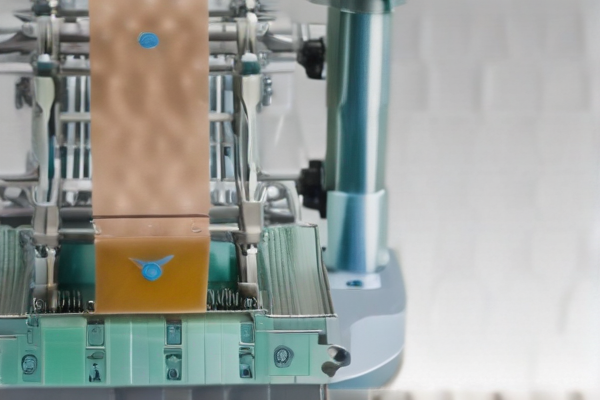

2. What materials are compatible with SourcifyChina joint packing machines?

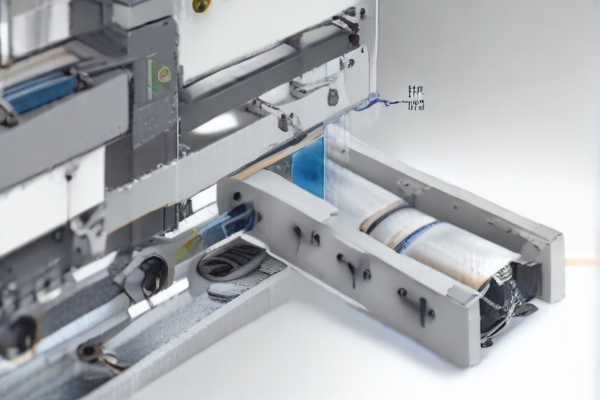

Our joint packing machines are compatible with a wide range of materials, including paper, plastic, foil, and various composite materials, ensuring flexibility and adaptability for different packaging requirements.

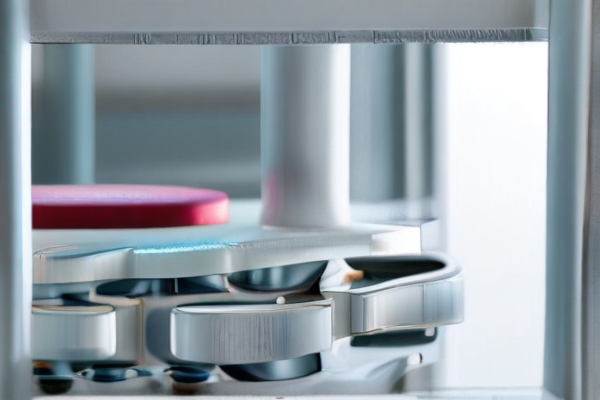

3. How do SourcifyChina machines ensure consistent quality in packaging?

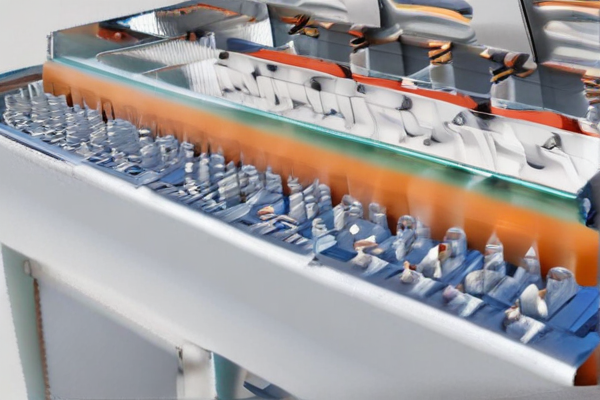

SourcifyChina machines are equipped with advanced control systems and high-precision components that ensure consistent sealing, accurate dosing, and uniform packaging. Regular quality checks are also performed during and after the manufacturing process.

4. Are SourcifyChina joint packing machines easy to operate?

Yes, our machines are designed with user-friendly interfaces and come with detailed manuals and training support to ensure that operators can quickly and easily learn to use them efficiently.

5. What is the typical lead time for an order of joint packing machines?

The lead time for our joint packing machines typically ranges from 4 to 8 weeks, depending on the specific model and customization requirements. We recommend contacting our sales team for a more accurate estimate based on your order.

6. Does SourcifyChina factory provide customization options?

Yes, we offer customization options to cater to your specific needs, including different sizes, capacities, and additional features. Our engineering team works closely with clients to deliver tailored solutions.

7. What kind of after-sales support does SourcifyChina provide?

We provide comprehensive after-sales support, including installation assistance, troubleshooting, maintenance services, and spare parts supply to ensure the long-term performance and reliability of our machines.

8. How does SourcifyChina ensure the durability of their joint packing machines?

Our machines are manufactured using high-quality materials and components, rigorously tested for durability, and built to withstand continuous operation under demanding conditions. Regular maintenance and proper handling further enhance their lifespan.

9. Are there any warranties included with SourcifyChina joint packing machines?

Yes, SourcifyChina offers a standard warranty on all our joint packing machines, covering parts and labor for a specified period. The warranty details are available upon request and can vary depending on the machine model.