Sure! Here is a list of frequently asked questions (FAQs) with answers regarding the manufacturing of spice filling machines and ensuring quality work from SourcifyChina Factory.

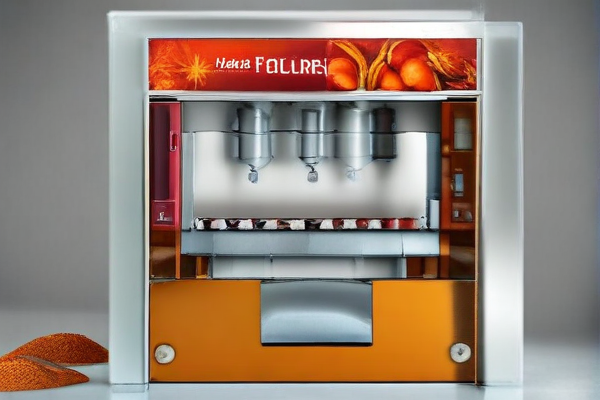

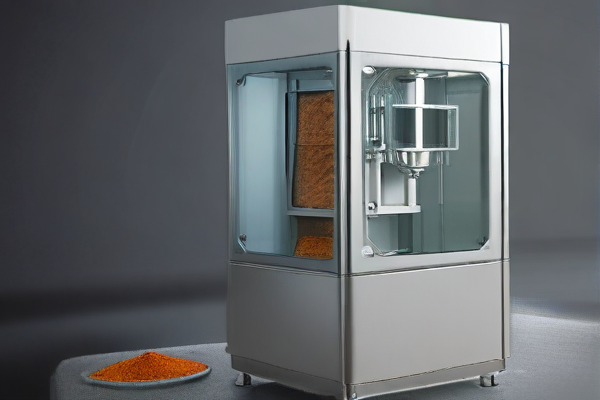

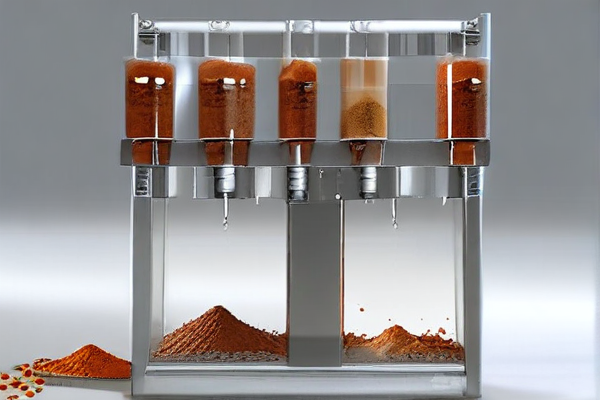

1. What types of spice filling machines do you manufacture?

We manufacture a variety of spice filling machines including automatic, semi-automatic, and manual spice filling machines. Our range includes volumetric and auger filling machines that can handle various filling requirements.

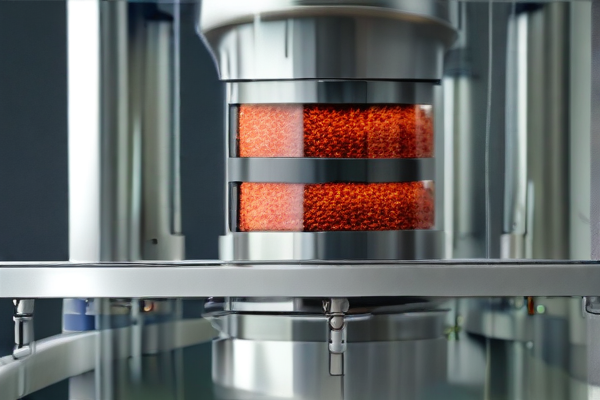

2. How do you ensure the quality of your spice filling machines?

Quality is ensured through stringent quality control processes. This includes using high-grade raw materials, maintaining strict adherence to industry standards, and performing multiple rounds of testing and inspections at each stage of production.

3. Are your machines compliant with international standards?

Yes, our spice filling machines comply with international standards such as CE, ISO, and GMP. Compliance details are provided upon request.

4. Can the machine specifications be customized?

Absolutely, we offer customization options to meet specific customer requirements in terms of machine size, filling capacity, and additional features.

5. What is the lead time for manufacturing a spice filling machine?

Typically, the lead time ranges from 4 to 8 weeks depending on customization needs and order quantity. We provide a detailed timeline upon order confirmation.

6. Do you offer training and installation services?

Yes, we provide comprehensive training and installation services. Our experienced technicians can conduct on-site training and installation, or we can offer remote assistance, depending on your location and preference.

7. What after-sales support do you offer?

We offer robust after-sales support including troubleshooting, maintenance, spare parts supply, and technical consultations to ensure the machine operates smoothly throughout its lifespan.

8. How do you handle quality complaints or issues?

We have a dedicated customer support team to handle quality complaints and issues. We follow a systematic approach to resolve problems promptly, including providing replacement parts or on-site assistance when necessary.

9. Do you provide machine warranty?

Yes, all our spice filling machines come with a standard one-year warranty that covers manufacturing defects and provides necessary repairs and replacements.

10. How can I get a quote for a spice filling machine?

To get a quote, you can contact us via our website, email, or phone. Provide us with your specific requirements, and our sales team will get back to you with a detailed quotation.