Sure, here is a list of FAQs with answers for manufacturing a sealing packaging machine from the SourcifyChina factory:

Q: What is the typical lead time for manufacturing a sealing packaging machine?

A: The typical lead time for manufacturing a sealing packaging machine at SourcifyChina is approximately 4-6 weeks, depending on the complexity and customization requirements of the machine.

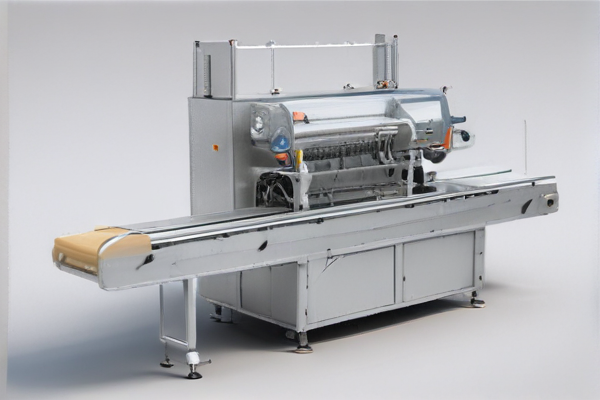

Q: How does SourcifyChina ensure the quality of the sealing packaging machines?

A: SourcifyChina adheres to strict quality control protocols, including multiple stages of inspection during production. They use high-quality materials and components, and all machines undergo thorough testing before shipment.

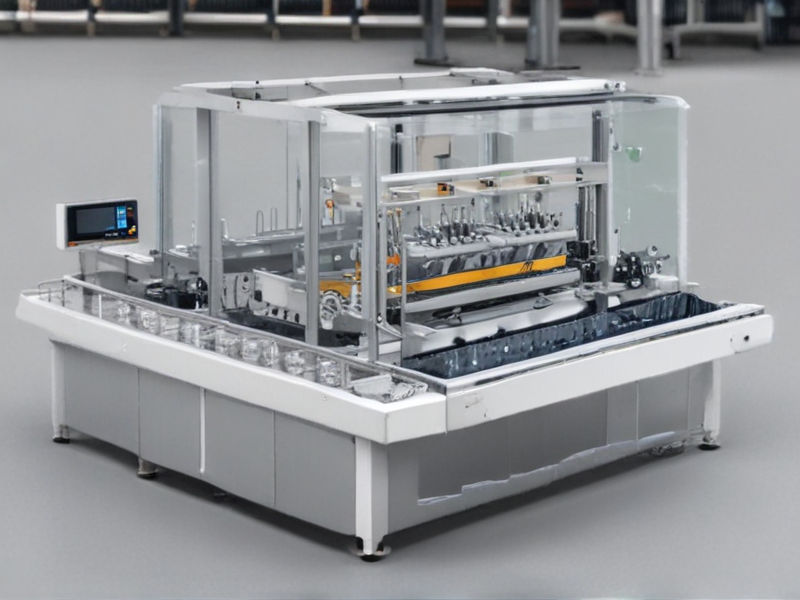

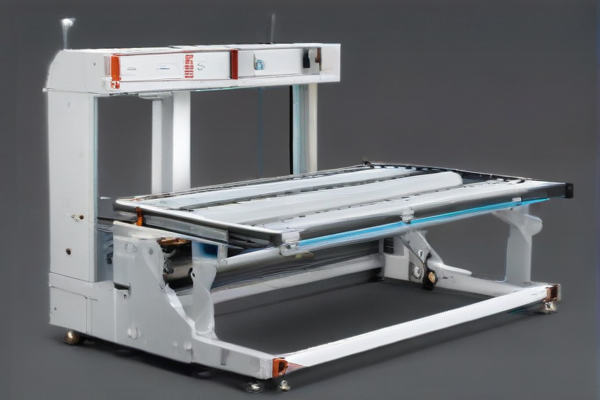

Q: Can the sealing packaging machines be customized to specific requirements?

A: Yes, SourcifyChina offers customization options to meet specific requirements, including changes in size, material compatibility, and additional functionalities as per client needs.

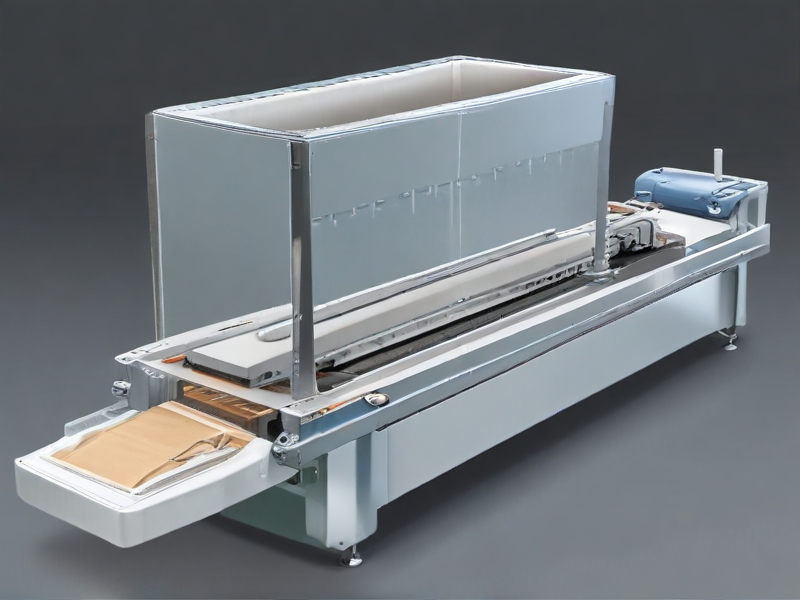

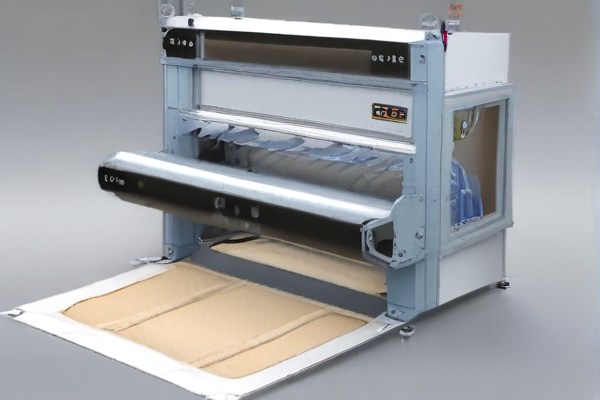

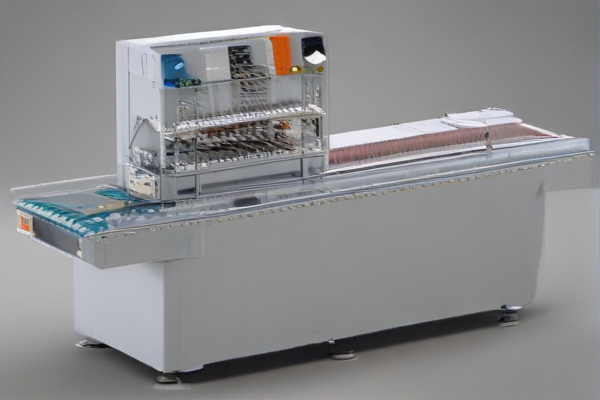

Q: What technology is used in the sealing packaging machines?

A: SourcifyChina uses advanced sealing technologies such as heat sealing, ultrasonic sealing, and vacuum sealing, depending on the application and material type.

Q: Are there any after-sales services available for the sealing packaging machines?

A: Yes, SourcifyChina provides comprehensive after-sales services including installation support, maintenance, and technical assistance to ensure optimal machine performance.

Q: What kind of training does SourcifyChina offer for operating their sealing packaging machines?

A: SourcifyChina offers detailed training sessions both on-site and online, covering machine operation, maintenance procedures, and troubleshooting tips to ensure smooth operation.

Q: What is the warranty period for the sealing packaging machines?

A: SourcifyChina provides a standard 1-year warranty on all sealing packaging machines, covering manufacturing defects and ensuring peace of mind for customers.

Q: How can I request a quote for a sealing packaging machine from SourcifyChina?

A: To request a quote, you can contact SourcifyChina directly through their website or email, providing your specific requirements and desired machine configuration.

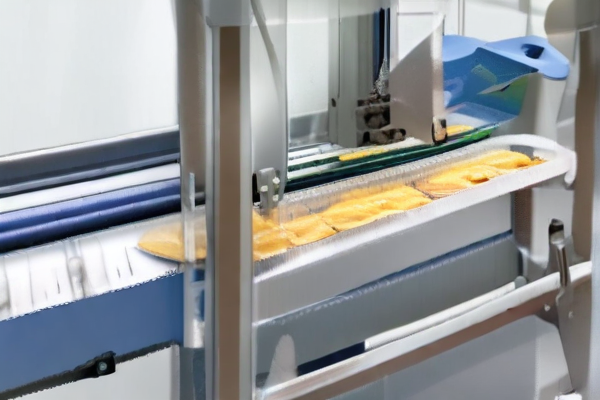

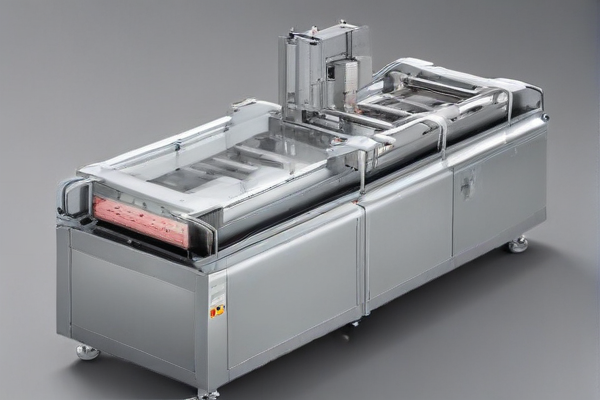

Q: Are the sealing packaging machines compatible with different types of packaging materials?

A: Yes, SourcifyChina designs their machines to be compatible with a wide range of packaging materials including plastic films, laminates, foils, and more.

Q: What distinguishes SourcifyChina’s sealing packaging machines from competitors?