Sure, here is a compact list of frequently asked questions (FAQ) with answers for sourcing a packing machine for powder from SourcifyChina factory:

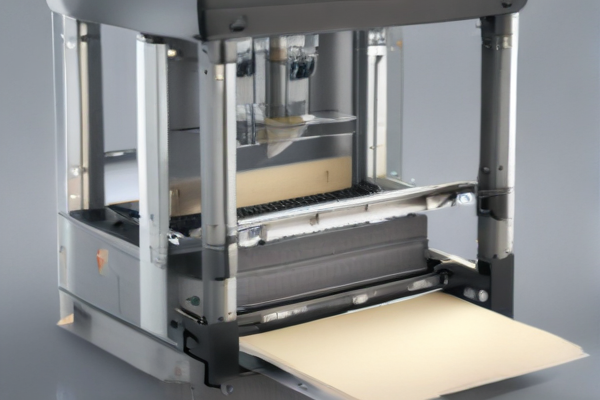

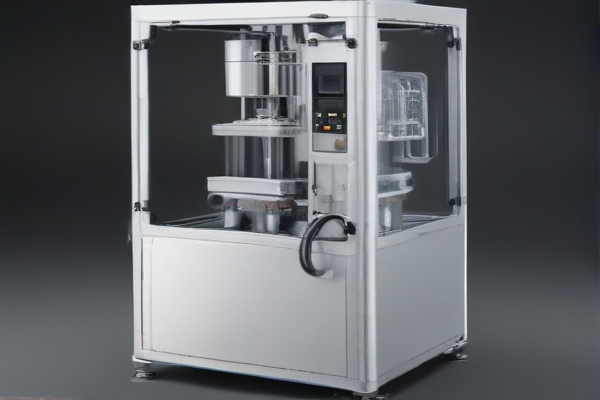

1. What types of powder packing machines do you offer?

We offer a range of powder packing machines including auger fillers, valve baggers, and vertical form fill seal (VFFS) machines tailored for various powder types and production scales.

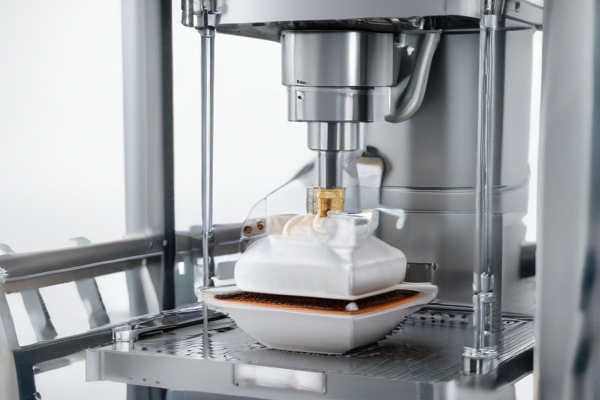

2. What are the key features of your powder packing machines?

Our machines feature automated controls, high precision dosing, customizable fill weights, stainless steel construction for hygiene, and various sealing options to ensure product integrity.

3. Can I customize the packing machine for my specific powder product?

Yes, customization options are available. We can tailor the machine for different powder properties, packaging materials, and production requirements to ensure optimal performance.

4. What is the average lead time for manufacturing and delivery?

The typical lead time for manufacturing is 6-8 weeks, followed by a delivery period that varies depending on your location. We provide detailed timelines once an order is confirmed.

5. Do your machines comply with international quality standards?

Absolutely. Our machines comply with international standards including CE certification for safety and GMP certification for hygiene and quality.

6. What kind of support and training do you provide for machine installation?

We offer comprehensive support including installation guides, on-site installation assistance, and operator training to ensure your team can efficiently run the machine.

7. What is your warranty and after-sales service policy?

Our machines come with a one-year warranty covering parts and labor. We also offer ongoing after-sales support including spare parts, maintenance services, and technical assistance.

8. How can I get a quote for a powder packing machine?

You can request a quote by contacting our sales team via our website or email. Please provide details about your product, packaging requirements, and production volumes for an accurate quote.

9. Can I visit SourcifyChina factory to see the machines in operation?

Yes, factory visits are encouraged. Schedule an appointment with our team, and we’ll be happy to demonstrate our machines and answer any questions.

10. What are the payment terms and options?

Our standard payment terms are 30% advance payment and 70% balance before shipment. We accept various payment methods including bank transfer and Letter of Credit (L/C).

This synthesized FAQ provides crucial information within 300 words, addressing common concerns and details for potential buyers.