FAQs on Manufacturing Meat Packaging Machines from SourcifyChina Factory

1. What types of meat packaging machines does SourcifyChina manufacture?

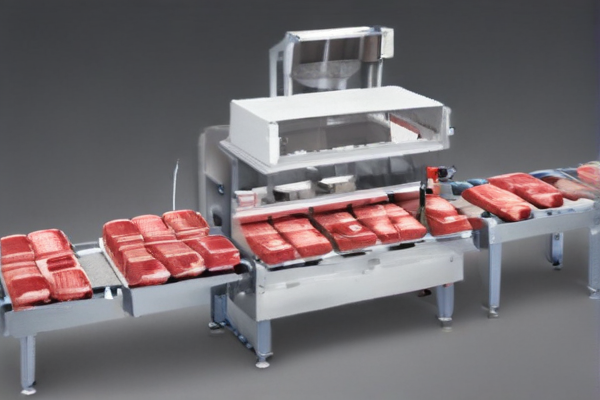

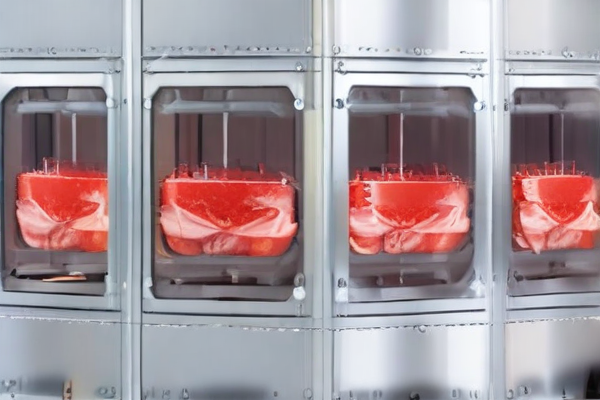

SourcifyChina manufactures a wide array of meat packaging machines including vacuum packaging machines, thermoforming machines, tray sealers, and automated weighing and packaging systems to meet diverse industry needs.

2. What quality standards does SourcifyChina adhere to?

SourcifyChina adheres to international quality standards such as ISO 9001 for quality management, and they ensure all machines comply with CE marking requirements for safety, health, and environmental protection.

3. How are the machines tested for quality?

Machines undergo rigorous testing that includes operational tests, performance checks, and preventive maintenance routines to ensure reliability and efficiency before shipment.

4. Can SourcifyChina customize machines to fit specific needs?

Yes, SourcifyChina offers customization options to meet specific client requirements, including custom dimensions, special features, and integration with existing systems.

5. What kind of support does SourcifyChina offer post-purchase?

SourcifyChina provides comprehensive post-purchase support including installation assistance, user training, a warranty period, and ongoing maintenance services.

6. How does SourcifyChina ensure timely delivery?

SourcifyChina has an efficient production schedule and reliable logistics partners to ensure timely delivery. They also provide real-time tracking and updates to the customers.

7. What materials are used in the construction of the packaging machines?

High-grade stainless steel and food-grade materials are used to construct the machines, ensuring durability, hygiene, and resistance to corrosion.

8. Are the machines energy-efficient?

Yes, SourcifyChina designs their machines to be energy-efficient, implementing the latest technologies to reduce power consumption while maintaining high performance.

9. Is there any training provided for operating the machines?

SourcifyChina offers comprehensive operator training, which includes hands-on instruction and detailed user manuals to ensure proper and safe machine operation.

10. Can I get a demo before purchasing a machine?

Demos are available upon request. Customers can visit the factory for an in-person demonstration, or virtual demos can be arranged online.

These FAQs aim to provide a concise understanding of what SourcifyChina offers in terms of quality manufacturing and support for meat packaging machines.