List Technical Parameters of "Seeds Packing Machine"

The Seeds Packing Machine is a specialized device designed to automate the process of packaging seeds. Below are the essential technical parameters:

1. Power Supply: Typically requires an AC source, either 220V/50Hz or 110V/60Hz, depending on regional standards.

2. Power Consumption: Ranges between 1 kW to 3 kW, based on machine complexity.

3. Capacity: Handles varying packaging speeds, generally 20-60 bags per minute.

4. Bag Size:

- Length: Adjustable between 50mm to 300mm.

- Width: Adjustable between 50mm to 200mm.

5. Filling Range: Can fill seeds between 10g to 1kg per bag.

6. Accuracy: Filling precision is typically around ±0.5% to ±1% of the fill weight.

7. Material Compatibility: Suitable for a wide range of packaging materials including polyethylene, polypropylene, and multi-layer laminated films.

8. Sealing Type: Heat sealing, ultrasonic sealing, or cold sealing, depending on material type.

9. Control System: Often utilizes a PLC (Programmable Logic Controller) for automated operation with a touch screen interface for easy parameter adjustment.

10. Operation Mode: Can be set to automatic or semi-automatic.

11. Hopper Capacity: Varies, but small machines generally have a 10L to 50L hopper.

12. Dimensions: Varies widely; common dimensions are around 1100mm (L) x 800mm (W) x 1500mm (H).

13. Weight: Typically around 200kg to 400kg depending on the model and additional features.

14. Conveyor Speed: Adjustable speed control to synchronize with packing speed.

15. Feeding Mechanism: Usually employs volumetric or gravimetric feeding systems.

16. Safety Features: Emergency stop buttons, safety guards, and sensors to prevent operation mishaps.

17. Optional Features: Can include printers for batch coding, date stamping, and barcoding, as well as nitrogen flushing systems for modified atmosphere packaging.

These parameters ensure efficiency, precision, and adaptability in various operational settings, meeting diverse packaging requirements.

List Product features of "Seeds Packing Machine"

Sure, here are the product features of a "Seeds Packing Machine":

1. High Precision Weighing: Advanced sensors and software ensure accurate weight measurement, reducing wastage and maximizing productivity.

2. Versatile Packaging Options: Supports various packaging materials like plastic, paper, and foil, and accommodates different packaging styles such as pouches, sachets, and bags.

3. User-Friendly Interface: Intuitive touch-screen controls simplify operation, enabling quick adjustments and setup changes.

4. Automated Operation: Fully automated filling, sealing, cutting, and labeling mechanisms streamline the packing process and enhance efficiency.

5. Adjustable Speed Control: Variable speed settings allow customization according to the type and quantity of seeds being packed, optimizing performance.

6. Compact Design: Space-saving structure makes it suitable for different production environments, from large factories to small workshops.

7. Durable Construction: Made from high-quality stainless steel to withstand continuous operation and ensure longevity while maintaining hygiene standards.

8. Error Detection & Alarms: Built-in error detection systems alert operators to issues like low material levels, jammed packaging, or mechanical failures, minimizing downtime.

9. Energy Efficient: Optimized power consumption helps in reducing operational costs while maintaining high performance.

10. Easy Maintenance: Modular design simplifies cleaning and maintenance, ensuring the machine remains in optimal working condition with minimal downtime.

11. Customizable Settings: Programmable parameters let users fine-tune operations based on specific seed types and packaging requirements.

12. Compliance with Safety Standards: Equipped with safety features like emergency stop buttons and protective guards to ensure operator safety and compliance with industry standards.

13. Remote Monitoring & Control: Integration with IoT systems enables remote diagnostics and real-time monitoring for proactive maintenance and troubleshooting.

14. Scalability: Can be integrated with additional modules or machines for increased capacity, suitable for growing production needs.

These features collectively enhance the efficiency, reliability, and versatility of seed packing operations, making the Seeds Packing Machine a valuable asset for agricultural businesses.

List Application of "Seeds Packing Machine"

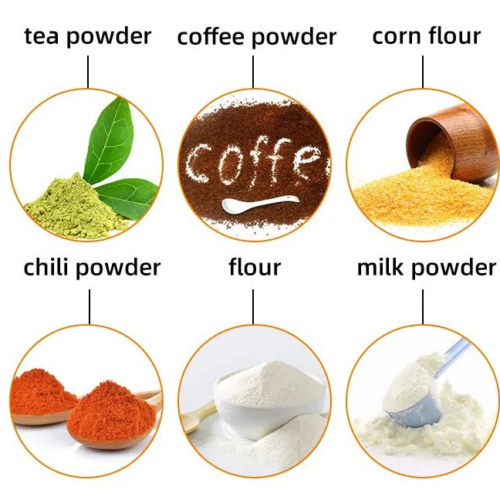

A seeds packing machine is a versatile and efficient tool designed to automate the process of packing seeds into various forms of packaging. It offers numerous applications across different industries. Below are some key applications:

1. Agricultural Sector: Primarily used to package seeds for planting, such as grains (wheat, rice, corn), vegetables, fruits, and flowers. It ensures precise quantity, enhances seed longevity, and reduces labor costs.

2. Horticulture Industry: Used for packing seeds in smaller lots for retail sales in garden centers and nurseries. The machine can handle a wide range of seed varieties, ensuring accurate weight and secure packaging to prevent contamination and seed loss.

3. Research Institutions: Facilitates the packaging of different seed varieties for experimental purposes. Consistent and accurate packing maintains experimental integrity and simplifies the distribution of seed samples.

4. Seed Banks: Assists in long-term storage by packing seeds in vacuum-sealed pouches, improving shelf life, and protecting against environmental factors like moisture and pests.

5. E-commerce: With the rise of online gardening stores, seeds packing machines enable businesses to swiftly fulfill and dispatch orders, ensuring timely delivery to customers.

6. Retail Packaging: Useful in creating consumer-friendly retail packets of seeds that include branding, planting guidelines, and other pertinent information, which enhances market appeal.

7. Bulk Packaging: For commercial farms or distributors who require large quantities of seeds packaged, the machine can handle high-volume packaging efficiently, saving time and reducing manpower.

8. Automated Distribution: Some machines integrate with automated distribution systems for direct feeding into other packaging lines or conveyor belts, promoting efficient workflow and reducing manual intervention.

In summary, seeds packing machines are integral across various industries for their accuracy, efficiency, and ability to preserve seed quality, thereby ensuring reliable supply chains and fostering agricultural productivity.

List Various Types of "Seeds Packing Machine"

Certainly! Here is a list of various types of seeds packing machines:

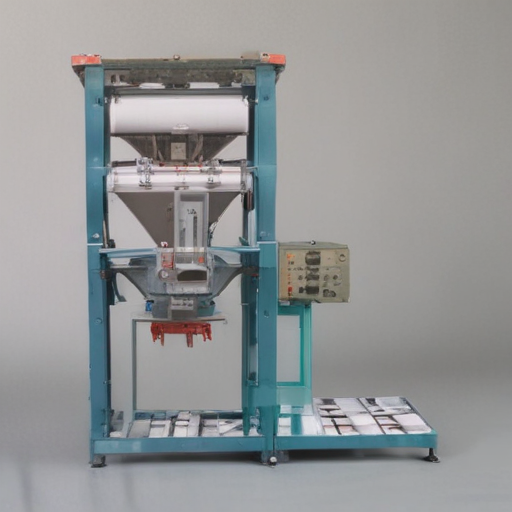

1. Vertical Form Fill Seal (VFFS) Machines:

- Creates bags from a flat roll of film.

- Suitable for high-speed packaging of seeds into small to medium-sized bags.

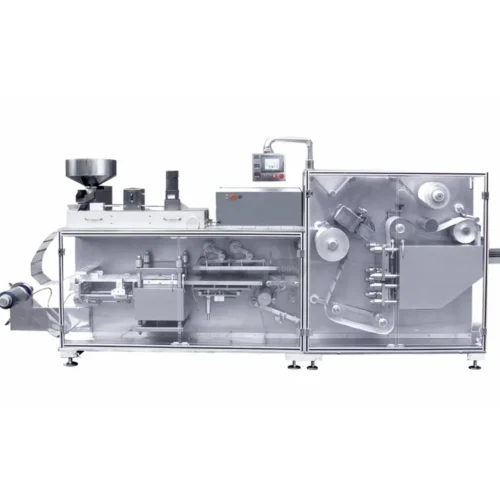

2. Horizontal Form Fill Seal (HFFS) Machines:

- Produces bags and pouches horizontally.

- Ideal for packing larger quantities of seeds with precision.

3. Automatic Weighing and Packing Machines:

- Integrates weighing scales and packing in one system.

- Accurate for packing precise amounts of seeds by weight.

4. Rotary Packing Machines:

- Utilizes a rotating table for filling pre-made bags.

- Efficient for high-speed operation and consistent packing results.

5. Stick Pack Machines:

- Designed for long, narrow stick packs.

- Suitable for individual, single-use portions of seeds.

6. Sachet Packing Machines:

- Specialized for small sachets.

- Commonly used for small quantities of seeds, ideal for sampling.

7. Gusseted Bag Packing Machines:

- Creates bags with side gussets for extra volume.

- Useful for packing larger quantities of seeds.

8. Multi-Head Weighing Packing Machines:

- Uses multiple weighing heads to enhance precision and speed.

- Optimized for bulk packing operations.

9. Pillow Bag Packing Machines:

- Produces pillow-shaped bags.

- Widely used for flexible, efficient seed packaging.

10. Vacuum Packing Machines:

- Removes air from the bag before sealing.

- Extends shelf life, suitable for seeds that need preservation.

11. Stand-Up Pouch Packing Machines:

- Creates pouches that can stand on their own.

- Attractive for retail packaging.

12. Grain and Seed Bagging Machines:

- Specially designed for heavy-duty packing.

- Suitable for larger, bulk quantities of seeds.

These machines cater to various needs and scale of operations, whether it be precision, speed, or specific packaging styles.

Custom Manufacturing Options for Seeds Packing Machine

Custom manufacturing options for seed packing machines cater to various demands, enhancing functionality, efficiency, and adaptability. Here are key customization aspects:

1. Packaging Formats: Machines can be tailored to accommodate different packaging types, including pouches, sachets, bottles, and tins, depending on market preferences and product requirements.

2. Capacity and Speed: Customizable speed and capacity options enable manufacturers to choose machines that match their production targets, ranging from small-scale operations to large, industrial-scale outputs.

3. Automation Levels: Options range from semi-automatic to fully automatic machines, offering different degrees of human intervention, advanced features like touch-screen interfaces, and integration with existing production lines.

4. Filling Systems: Depending on seed type and quantity, various filling systems such as volumetric fillers, weighers, or auger fillers can be incorporated to ensure precise and efficient handling.

5. Material Handling: Custom designs to accommodate fragile, light, or irregularly shaped seeds. Features include gentle conveyors, specialized hoppers, and anti-static mechanisms to handle delicate varieties.

6. Sealing Mechanisms: Machines can be equipped with diverse sealing technologies, such as heat sealing, ultrasonic sealing, or vacuum sealing, to enhance the shelf-life and integrity of the packages.

7. Printing and Labeling: Integration of date coding, batch numbering, and automated labeling systems facilitate compliance with regulatory requirements and enhance traceability and branding efforts.

8. Hygiene and Safety: Customization to meet specific hygiene standards is vital, particularly in seed industries where contamination can impact product quality. Features like stainless steel construction, easy-to-clean components, and safety guards can be incorporated.

9. Footprint and Layout: Machines can be customized in terms of size and layout to fit into existing production spaces, ensuring efficient flow and space utilization.

By addressing these customization options, manufacturers can enhance performance, meet specific production needs, and ensure product quality and compliance.

List Quality Control and The Manufacturing Process of "Seeds Packing Machine"

Quality control and the manufacturing process of a seeds packing machine involve multiple stages to ensure the machine meets the required standards and functions efficiently.

Manufacturing Process

1. Design and Development:

- Conceptualization: Define requirements, functionality, and design specifications.

- CAD Modeling: Create detailed 3D models and technical drawings.

- Prototyping: Develop a prototype for testing and validation.

2. Materials Selection:

- Choose high-quality metals, electronics, and other components based on durability, performance, and compliance with industry standards.

3. Component Manufacturing:

- Machining: Precision machining of parts like frames, gears, and other mechanical components.

- Fabrication: Welding, cutting, and forming metal sheets for various machine parts.

- Electronic Assembly: Assemble and test electronic control systems, sensors, and actuators.

4. Sub-Assembly:

- Assemble individual components into sub-systems such as the feeding system, weighing system, and sealing mechanism.

5. Final Assembly:

- Integrate all sub-systems into the main machine frame.

- Install wiring, software, and user interface controls.

6. Calibration and Testing:

- Calibrate weighing and filling mechanisms for accuracy.

- Run trial operations to check functionality and performance.

Quality Control

1. Incoming Materials Inspection:

- Verify quality and specifications of raw materials and components before production.

2. In-Process Inspection:

- Machining Checks: Measure and inspect machined parts for dimensional accuracy.

- Fabrication Checks: Inspect welded and formed parts for defects.

- Assembly Checks: Verify correct assembly of sub-systems and components.

3. Final Machine Testing:

- Perform comprehensive functional testing under various operating scenarios.

- Test for packaging accuracy, speed, and reliability.

- Conduct safety checks to ensure compliance with regulations.

4. Quality Audits:

- Periodically review and assess manufacturing and quality control processes to ensure continuous improvement.

5. Customer Feedback:

- Gather feedback on machine performance and incorporate necessary improvements in future designs and manufacturing processes.

By adhering to rigorous quality control and structured manufacturing processes, the seeds packing machine is ensured to be reliable, efficient, and compliant with industry standards.

How to use "Seeds Packing Machine"

Using a Seeds Packing Machine involves several key steps to ensure efficient and accurate packaging of seeds. Follow this basic guide to operate the machine:

1. Setup:

- Position the machine on a stable, level surface.

- Connect the machine to a suitable power source.

- Ensure all safety guards are in place.

2. Calibration:

- Set the desired weight or quantity of seeds per packet using the control panel.

- Adjust the bag size settings if the machine has adjustable packaging dimensions.

3. Loading:

- Pour seeds into the machine's hopper; ensure it is loosely filled to avoid jamming.

- If required, attach the appropriate feeding mechanism to ensure consistent seed flow.

4. Programming:

- Input necessary data such as the number of packets, speed, and idle time between packets.

- Select the packing mode (e.g., manual or automatic).

5. Packaging Material Setup:

- Load the roll of packaging film or pre-formed bags into the machine.

- Ensure the film or bags are properly threaded through the machine’s guides and sealing units.

6. Trial Run:

- Conduct a trial run with a small quantity to confirm settings.

- Check for accuracy in weight, seal integrity, and overall package quality.

7. Operation:

- Start the machine and monitor for consistent performance.

- Regularly check the hopper and refill seeds to maintain a steady operation.

8. Quality Control:

- Periodically inspect packaged seeds for weight accuracy and seal quality.

- Make necessary adjustments if any inconsistencies arise.

9. Shutdown:

- Once packaging is complete, turn off the machine.

- Clean the machine thoroughly to remove any seed residues.

- Disconnect from the power source and cover the machine if not in use.

Always refer to the manufacturer's manual for specific instructions and safety guidelines tailored to your particular machine model.

List Properties and Terms of "Seeds Packing Machine"

Sure! Here's a concise overview of the properties and terms associated with a Seeds Packing Machine:

Properties:

1. Automation Level:

- Fully Automatic: Minimal human intervention.

- Semi-Automatic: Requires some manual operation.

2. Capacity:

- Throughput: Measured in units per hour or per minute.

- Hopper Volume: Determines the batch load size.

3. Accuracy:

- Precision in weight or count of seeds per package.

- Typically measured in grams or milligrams deviation.

4. Material Compatibility:

- Supports various seed types: grains, pulses, etc.

- Hopper and contact parts often made of stainless steel to avoid contamination.

5. Packaging Types:

- Pouches: Laminated, foil, or plastic.

- Bags: Paper, woven, or plastic.

6. Sealing Methods:

- Heat sealing.

- Zip lock sealing.

7. Size and Dimensions:

- Compact or large, affecting floor space.

8. Power Consumption:

- Measured in kW.

- Depends on the automation level and capacity.

Terms:

1. Feeder System: Mechanism that channels seeds from hopper to packaging.

2. Hopper: A funnel-shaped container holding seeds ready for packing.

3. Conveyor Belt: Transports packaging material to the filling station.

4. Weighing Mechanism: Ensures accurate seed quantity in each pack.

5. Filling Nozzle: Dispenses seeds into the packaging material.

6. Sealing Jaw/Tool: Closes and seals the pack.

7. Control Panel: User interface for operational settings and monitoring.

8. PLC (Programmable Logic Controller): Handles automatic operations, increasing efficiency and consistency.

9. Maintenance Features:

- Easy Clean: Parts can be easily disassembled and cleaned.

- Spare Parts: Availability for replacements.

This concise list of properties and terms provides a foundational understanding of seeds packing machines, helping in making informed decisions on their use and purchase.

List The Evolution history of "Seeds Packing Machine"

The evolution of seeds packing machines reflects significant technological advancements to enhance efficiency, accuracy, and versatility.

1. Manual Packing (Pre-20th Century): Initially, seed packing was done manually. Workers filled packets by hand, a labor-intensive and time-consuming process prone to human error and inefficiency.

2. Mechanized Packing (Early 20th Century): The introduction of basic mechanical seed packing machines marked the first major leap. These were simple machines capable of performing repetitive tasks like filling and sealing but required manual oversight.

3. Semi-Automatic Machines (Mid-20th Century): Development of semi-automatic machines allowed partial automation. Machines such as volumetric filling devices were introduced, and operators had to oversee multiple machines, significantly improving productivity while still maintaining some reliance on manual operations.

4. Fully Automatic Machines (Late 20th Century): The advent of fully automatic seed packing machines represented a breakthrough. These machines could perform multiple tasks including weighing, filling, sealing, and labeling autonomously. Technologies such as load cells for precise weighing and programmable logic controllers (PLCs) enhanced performance and versatility.

5. Integration of Electronics (Late 20th to Early 21st Century): Incorporation of microprocessors and advanced electronic systems allowed for higher precision and control. Features like touch screens, electronic sensors, and automated adjustments became standard, ensuring consistent and accurate packing.

6. Smart and Robotic Systems (21st Century): In recent years, smart technology and robotics have revolutionized seed packing machines. Innovations include IoT (Internet of Things) for real-time monitoring, AI-driven systems for predictive maintenance and optimization, and robotic arms for complex packing tasks. These advancements minimize human intervention and maximize efficiency and adaptability.

7. Sustainable Design (Present and Future): Current trends focus on eco-friendly designs, reducing waste, and utilizing sustainable materials. Furthermore, enhanced software and machine learning algorithms continue to refine operations, aiming towards completely autonomous factory lines.

The progression from manual to fully automated and smart systems has drastically improved seed packing processes, addressing both efficiency and accuracy while incorporating sustainable practices.

How to Select a Reliable Seeds Packing Machine

Selecting a reliable seeds packing machine involves careful consideration of several factors to ensure efficiency, durability, and suitability for your specific needs. Here's a concise guide:

1. Determine Your Requirements: Identify the types of seeds you need to pack, the desired packaging size, and the production volume. This helps in choosing a machine that meets your specific capacity and packaging needs.

2. Quality and Build: Opt for machines made from high-quality materials, preferably stainless steel, to ensure durability and ease of maintenance. Verify the build quality to withstand continuous operation and resist corrosion.

3. Technology and Features: Look for advanced features like automatic weighing, filling, sealing, and error detection for efficient operation. Ensure the machine can handle different packaging styles (e.g., sachets, pouches).

4. Ease of Use and Maintenance: Choose a user-friendly machine with a simple interface for ease of operation. Additionally, consider the maintenance requirements and availability of spare parts to minimize downtime.

5. Manufacturer Reputation: Prefer reputable manufacturers with positive reviews and a track record of reliability. Check for certifications and standards compliance (ISO, CE) to ensure quality.

6. After-Sales Support: Reliable customer service and technical support are crucial. Ensure the manufacturer offers comprehensive after-sales support, including training, installation, and prompt service.

7. Cost and ROI: While cost is vital, focus on the overall value. An initially higher investment in a quality machine can result in better performance, longevity, and lower operational costs, providing a better return on investment.

By carefully evaluating these factors, you can select a seeds packing machine that enhances productivity and ensures reliable, long-term operation.

List "Seeds Packing Machine" FAQ

Certainly! Here are some frequently asked questions (FAQs) about "Seeds Packing Machines":

Seeds Packing Machine FAQ

-

What types of seeds can be packed using these machines?

Seeds packing machines are versatile and can handle a variety of seeds including vegetable seeds, flower seeds, grain seeds, and other small particulate products. -

What packaging materials are suitable?

These machines typically support a range of packaging materials such as plastic, aluminum foil, laminated films, and paper. -

How does the machine maintain the quality of the seeds?

Modern seeds packing machines are designed with features to minimize exposure to air and moisture, thereby preserving seed quality. Some machines may also include vacuum sealing options. -

What are the typical packaging sizes?

These machines can be configured to handle various packaging sizes, from small sachets (as low as 1 gram) to larger bags (up to several kilograms). -

Is it easy to operate the machine?

Yes, most seeds packing machines feature user-friendly interfaces, often with touch screens and programmable settings for different seeds and package sizes. -

How reliable are these machines?

High-quality seeds packing machines are built for durability and reliability, with many offering features such as error detection, automatic adjustments, and robust construction. -

Can the machine print labels or dates?

Yes, many models come with integrated printing systems to add labels, barcodes, or expiration dates onto the packaging. -

What is the speed of the machine?

The speed varies depending on the model and configuration, but can range from 20 to 100+ packs per minute. -

What kind of maintenance is required?

Regular maintenance such as cleaning, lubrication, and inspection is necessary. Many machines also come with diagnostic tools to help identify issues early. -

How much does a seeds packing machine cost?

Prices range significantly based on capabilities, quality, and brand. Entry-level models may start around a few thousand dollars, while high-end machines can cost several tens of thousands. -

Is technical support available?

Yes, most manufacturers offer technical support, warranties, and sometimes even training sessions for operators.

By addressing these common questions, one can better understand the functionality, versatility, and maintenance requirements of seeds packing machines.

Top 10 FAQ with answer about Seeds Packing Machine for Buyer Sourcing from China

Sure! Here are the top 10 frequently asked questions about sourcing seed packing machines from China, with concise answers:

-

What types of seed packing machines are available?

Seed packing machines come in various types including vertical form fill seal (VFFS) machines, horizontal form fill seal (HFFS) machines, sachet packing machines, and vacuum packing machines. The choice depends on the packaging style and volume of seeds. -

What's the typical lead time for production and delivery?

The lead time typically ranges from 4 to 8 weeks, including manufacturing, quality testing, and shipping. This can vary based on order complexity and factory capacity. -

How can I ensure the quality of the seed packing machine?

Look for reputable manufacturers with ISO certification and positive customer reviews. Request for quality assurance processes, factory visit videos, and third-party inspection reports. -

What payment terms are commonly accepted?

Most manufacturers accept T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes PayPal or Western Union for smaller amounts. An initial deposit (usually 30%) may be required, with the remaining balance paid before shipment. -

Are there any shipping restrictions or regulations I should be aware of?

Seed packing machines are generally considered standard industrial equipment and are not heavily regulated. However, always check import regulations specific to your country. -

Do these machines come with a warranty?

Yes, most machines come with a 1-year warranty covering parts and labor. Some manufacturers may offer extended warranties for an additional fee. -

Can the machines handle different types of seeds?

Yes, most machines are designed to be versatile and can handle a variety of seeds (e.g., sunflower, sesame, chia) with minor adjustments to settings. -

What after-sales support is available?

Manufacturers typically offer remote technical support via phone, email, or video call. Some may also have local service partners for on-site support. -

Are spare parts readily available?

Reputable manufacturers ensure that spare parts are available for at least 5-10 years. They also provide manuals and guidance on how to replace parts. -

How do I ensure the machine meets my country's safety standards?

Confirm that the machine complies with international standards like CE (European Conformity) or UL (Underwriters Laboratories). Request certification documents from the manufacturer.

By keeping these FAQs in mind, buyers can make more informed decisions when sourcing seed packing machines from China.