List Technical Parameters of “rotary capping machine”

Rotary capping machines are widely used in the packaging industry to seal bottles with caps of different sizes and shapes. These machines are designed with various technical parameters that ensure their efficiency, accuracy, and reliability. Here are some of the most important technical parameters of rotary capping machines:

1. Cap size range: This is the range of cap sizes the machine can handle. It determines the versatility of the machine and its suitability for different applications.

2. Production speed: This is the number of bottles the machine can cap per minute. It depends on the machine’s design, the number of capping heads, and the type of caps and bottles being used.

3. Capping force: This is the force applied by the capping heads to seal the caps on the bottles. It should be adjusted to suit the cap and bottle materials and the tightness required.

4. Capping head type: There are different types of capping heads, such as chuck cappers, snap cappers, and screw cappers. The choice depends on the cap type, bottle type, and production speed.

5. Cap feeding system: This is the system that delivers the caps to the capping heads. It can be a vibratory bowl feeder, an elevator, or a pick-and-place system.

6. Bottle handling system: This is the system that positions and stabilizes the bottles during capping. It can use indexing starwheels, conveyor belts, or gripper belts.

7. Control system: This is the electronic system that controls the machine’s operations, including the production speed, capping force, and cap and bottle handling.

8. Material of construction: The machine should be made of durable, corrosion-resistant materials that can withstand the harsh conditions of the packaging environment.

9. Power supply requirements: The machine should be designed to work with the available power supply, such as single-phase or 3-phase, and the voltage and frequency should be specified.

In conclusion, these are some of the key technical parameters that determine the performance and effectiveness of a rotary capping machine. They should be carefully considered when selecting a machine to ensure it is suitable for the intended application.

List Product features of “rotary capping machine”

Rotary capping machines are used in the packaging industry to securely seal containers using caps and lids. Here are some of the main features of rotary capping machines:

1. High speed: Rotary capping machines have a high capping speed, which means they can cap a large number of bottles or containers in a short amount of time.

2. Versatile: Rotary capping machines can be used to cap a wide range of containers, including bottles, jars, and tubes. They can also cap different types of caps, such as screw caps, snap-on caps, and flip-top caps.

3. Easy to operate: Rotary capping machines are designed to be user-friendly and easy to operate. They have intuitive controls that allow operators to adjust the capping speed, torque, and other settings according to their needs.

4. Accurate capping: Rotary capping machines use advanced technology to ensure accurate and consistent capping. They can adjust the capping torque to suit different types of caps and containers, ensuring that the caps are tightly sealed without damaging the container.

5. Fault detection: Rotary capping machines are equipped with sensors and other devices that detect faults or errors in the capping process. This helps to prevent issues such as caps being incorrectly placed or over-tightened.

6. Compact design: Rotary capping machines have a compact design that takes up less floor space than other types of capping machines. This makes them ideal for use in small to medium-sized packaging facilities.

7. Easy maintenance: Rotary capping machines are designed to be easy to maintain and clean. They have fewer moving parts than other types of capping machines, which means they require less maintenance and have fewer components that can become worn or damaged over time.

8. Durability: Rotary capping machines are built to last. They are made from high-quality materials and components that are designed to withstand the rigors of high-speed capping operations.

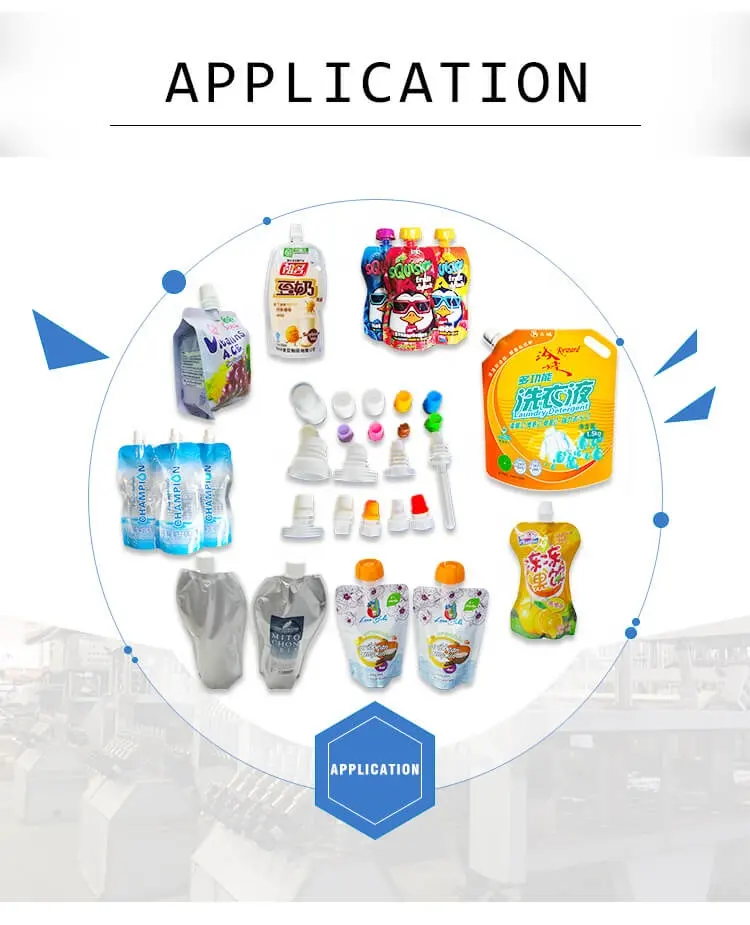

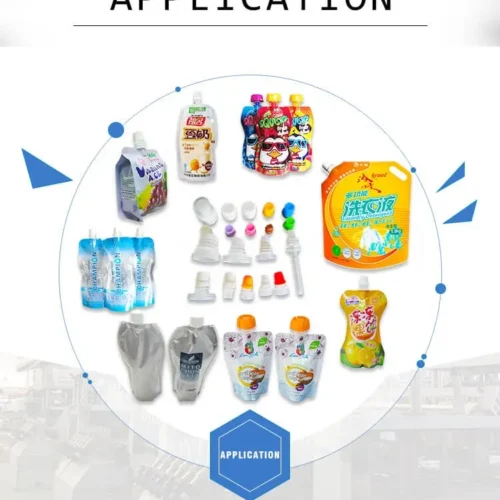

List Application of “rotary capping machine”

Rotary capping machines are utilized for capping different types of bottles, jars, vials, and containers. They are widely used in various industries, including pharmaceutical, food and beverage, cosmetic, chemical, and petrochemical.

Here are the applications of rotary capping machines:

1. Pharmaceutical Industry: In the pharmaceutical industry, rotary capping machines are used for capping bottles of different sizes, shapes, and materials. The machines are designed to meet the strict regulatory requirements of the industry and ensure the safety and quality of the products.

2. Food and Beverage Industry: In the food and beverage industry, rotary capping machines are used for capping bottles of various liquids, including water, juices, and carbonated drinks. The machines are designed to maintain the quality and freshness of the products and ensure that they are properly sealed.

3. Cosmetic Industry: In the cosmetic industry, rotary capping machines are used for capping bottles of various cosmetics and skincare products, including lotions, creams, and shampoos. The machines are designed to ensure that the products are properly sealed and prevent any contamination.

4. Chemical Industry: In the chemical industry, rotary capping machines are used for capping containers of various chemicals, including acids, solvents, and fertilizers. The machines are designed to handle the corrosive and hazardous nature of the chemicals and ensure that they are properly sealed.

5. Petrochemical Industry: In the petrochemical industry, rotary capping machines are used for capping drums of various oils, lubricants, and other petrochemical products. The machines are designed to handle the high viscosity and high-pressure nature of the products and ensure that they are properly sealed.

Overall, rotary capping machines are essential for different industries for their sealing and capping needs. They enhance the quality of products, ensure the safety of consumers, and increase productivity and efficiency.

List Various Types of “rotary capping machine”

A rotary capping machine is a packaging equipment used to seal caps onto containers such as bottles, jars, and vials. Rotary capping technology is preferred in industries that require high-speed capping because it can cap bottles at a faster rate and can accommodate different cap sizes and shapes. Here are various types of rotary capping machines:

1. Single head rotary capping machine

This is a basic rotary capping machine consisting of a single capping head. It is suitable for low to medium production rate operations.

2. Multi-head rotary capping machine

This type of capper has multiple capping heads, typically ranging from 4 to 12 heads. It is best suited for high-speed production lines that require consistent cap sealing.

3. Spindle capping machine

Spindle capping machines use rotating spindles to screw caps onto containers. They are suitable for capping round, square, and rectangular bottles.

4. Chuck capping machine

Chuck capping machines use an adjustable chuck to grip and rotate containers during the capping process. They are suitable for capping bottles with irregular shapes.

5. Snap capping machine

Snap capping machines use a pressure mechanism to snap plastic snap-on type caps onto bottles. They are commonly used in the food and beverage industry.

6. Press-on capping machine

Press-on capping machines use pressure to apply push-on or press-fit type caps onto containers. They are suitable for capping small bottles that require a higher level of precision.

7. ROPP cap sealing machine

ROPP (roll on pilfer-proof) cap sealing machines are used for sealing aluminum screw caps onto bottles. They are common in wine and liquor bottling plants.

In conclusion, rotary capping machines come in different configurations, and each is designed to meet specific production needs. Businesses must choose the right capping machine that suits their production requirements to ensure efficient and accurate operations.

List The Process of “rotary capping machine”

A rotary capping machine is a type of equipment that is used to cap bottles and containers. The machine uses a rotary system to apply caps on containers accurately and efficiently. Here’s a detailed process of how the machine works:

1. Feeding and Sorting: The first step when using a rotary capping machine is to feed the containers into the system. The machine is designed to feed, sort, and orient containers before they are capped.

2. Capping head: Once the containers are properly sorted, the capping head applies the cap. The capping head is designed to screw or snap the cap onto the container.

3. Torque adjustment: Many rotary capping machines have torque adjustment systems that allow for the regulation of the level of torque applied to the cap. The torque adjustment system can be used to change the tightness of the caps depending on the container type and size.

4. Cap Inspection: After caps are applied, the capping machine checks to ensure all caps are correctly placed on the containers.

5. Reject Station: Once the caps are checked, containers with damaged caps are removed, sorted, and tagged.

6. Exit Conveyor: The capped containers are then conveyed out of the machine.

The rotary capping machine is designed to cap containers accurately, with a higher level of efficiency than manual capping. It can be used in different industries like food, pharmaceutical companies, and cosmetic industries. Rotary capping machines are a lifesaver in the manufacturing industries because of their high speed, efficiency, and accuracy. Overall, the rotary capping machine is a reliable solution for capping needs.

How to use “rotary capping machine”

A rotary capping machine is a piece of equipment used in the packaging industry to seal a wide variety of containers, such as bottles, jars, and cans. It is used to ensure that the product inside the container is leak-proof, tamper-proof, and has a longer shelf life. The following are the steps on how to use a rotary capping machine:

1. Inspection: Before using the capping machine, it is necessary to inspect the containers to ensure they are clean, dry, and free from any particles or dust.

2. Adjustments: The capping machine needs to be adjusted according to the size and shape of the container, as well as the type of cap to be used. This is done by changing the star wheel and adjusting the capping heads.

3. Loading: The containers are loaded onto the machine’s conveyor belt, which moves them along to the capping station.

4. Capping: The caps are loaded into the feeding hopper, which moves them to the capping heads. The capping heads apply the caps to the containers and tighten them securely.

5. Inspection: After capping, the containers are inspected to ensure that the caps are securely fastened, and the product inside is leak-proof and tamper-proof.

6. Unloading: The finished containers are moved along the conveyor belt and unloaded from the machine.

7. Maintenance: After use, the machine should be thoroughly cleaned, and any parts that require maintenance or replacement should be attended to promptly.

In conclusion, using a rotary capping machine is a straightforward process that requires attention to detail and proper maintenance. By following the steps above, one can ensure that the packaging process is efficient, and the end-product is of high-quality.

List Properties of “rotary capping machine”

A rotary capping machine is a type of packaging equipment that is used to fit caps on bottles. The machine is designed to handle a large volume of containers and is widely used in the food and beverage, pharmaceutical, and chemical industries. The main properties of a rotary capping machine include:

1. Speed – A rotary capping machine is known for its high-speed operation. It can cap up to 1000 bottles per minute, depending on the size and shape of the bottle.

2. Versatility – The machine can handle a wide range of bottle sizes and shapes, from small vials to larger bottles. It is also compatible with different types of caps, including screw caps, snap-on caps, and cork caps.

3. Accuracy – The machine is designed to cap bottles with precision and consistency. It ensures that the caps are placed on the bottles at the correct angle and with the correct amount of torque.

4. Durability – Rotary capping machines are built to last and can withstand the wear and tear of high-speed operation. They are usually made from stainless steel, which is resistant to corrosion and easy to clean.

5. Automation – A rotary capping machine can be fully automated, which means it requires minimal human intervention. The machine can be integrated into a production line and controlled using a programmable logic controller (PLC) or human-machine interface (HMI).

6. Safety – Rotary capping machines are equipped with safety features such as emergency stop buttons and safety interlocks. These features ensure that the machine stops when there is a problem or when an operator is in danger.

In conclusion, a rotary capping machine is a highly efficient, versatile, accurate, durable, automated, and safe packaging equipment. It is a crucial component of modern production lines, as it enables manufacturers to cap bottles quickly and accurately.

List “rotary capping machine” FAQ

1. What is a rotary capping machine?

A: A rotary capping machine is a type of packaging machinery that is used to cap bottles or containers in a continuous rotary motion.

2. What types of caps can a rotary capping machine handle?

A: Rotary capping machines can handle a wide range of caps including screw caps, press-on caps, snap-on caps, and more.

3. What industries typically use rotary capping machines?

A: Rotary capping machines are used in a variety of industries including food and beverage, pharmaceutical, cosmetics, and chemicals.

4. What is the production rate of a rotary capping machine?

A: The production rate of a rotary capping machine depends on factors like the size of the machine, the type of cap, and the speed of the rotary motion. Most rotary capping machines can cap between 80 to 120 bottles per minute.

5. Can rotary capping machines handle different bottle sizes?

A: Yes, rotary capping machines can handle different bottle sizes and shapes as long as they are within the machine’s specifications.

6. Is a rotary capping machine easy to operate?

A: Yes, most rotary capping machines are designed to be user-friendly with easy-to-understand operational controls.

7. What types of maintenance are required for a rotary capping machine?

A: Regular cleaning and lubrication are important for the proper functioning of a rotary capping machine. Additionally, parts may need to be replaced periodically.

8. Can a rotary capping machine be customized for specific needs?

A: Yes, the design of a rotary capping machine can be customized based on the specific needs of an industry or product.

9. What safety features are included in a rotary capping machine?

A: Rotary capping machines are equipped with safety features such as emergency stop buttons, safety barriers, and automatic shut-off in case of malfunction.

10. What is the lifespan of a rotary capping machine?

A: The lifespan of a rotary capping machine depends on factors like usage, maintenance, and quality of the machine. Generally, a well-maintained rotary capping machine can last for several years.