In today’s fast-paced world, efficiency and precision are paramount, especially in the packaging industry. As businesses strive to meet the ever-growing demands of consumers, the need for advanced machinery that can streamline operations becomes evident. Enter the automatic canning machine – a revolutionary piece of equipment that has transformed the way products are packaged.

The packaging industry has witnessed significant advancements over the years, with technology playing a pivotal role in shaping its future. Among the various machines that have made a mark, the automatic canning machine stands out, offering unparalleled efficiency and accuracy. This article delves deep into the world of automatic canning machines, exploring their features, benefits, and the importance of choosing the right equipment for businesses.

Whether you’re a business owner looking to upgrade your packaging process or a curious individual eager to learn more about this fascinating machinery, this comprehensive guide will provide you with all the insights you need.

What is an Automatic Canning Machine?

The automatic canning machine, as the name suggests, is a sophisticated piece of equipment designed to automate the process of filling and sealing cans. Gone are the days when manual labor dominated the canning industry. With the advent of technology, these machines have revolutionized the packaging sector, ensuring faster production rates, consistent quality, and reduced wastage.

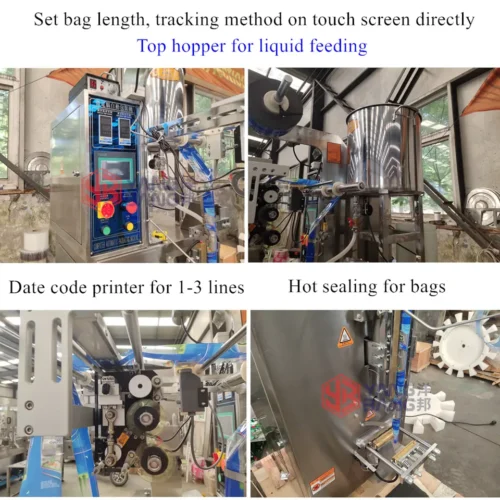

Historically, canning was a labor-intensive process, often prone to errors and inconsistencies. However, with the evolution of technology, modern canning machines have incorporated advanced features like PLC controls, touch screens, and precision sensors. These innovations not only enhance the machine’s efficiency but also ensure that the end product meets the highest standards of quality.

Types and Applications of Automatic Canning Machines

Automatic canning machines are versatile, catering to a wide range of products. From dairy items like milk and yogurt to beverages like fruit juices and beers, these machines ensure that products are packaged efficiently and safely. The choice between slim CAN and stubby CAN further allows businesses to customize their packaging based on the product and market demand.

The Manufacturing Process Behind the Machine

Quality is paramount when it comes to machinery, and the manufacturing process plays a significant role in determining it. HTK’s rigorous measures ensure that every machine is top-notch. From the design phase to testing, meticulous scrutiny is applied to guarantee the highest standards. Furthermore, with a team of specialists overseeing the production, businesses can rest assured that they are investing in a machine that is not only reliable but also technologically advanced.

How to Operate the Automatic Canning Machine?

Operating an automatic canning machine might seem daunting at first, but with the right guidance, it becomes a seamless process. Here’s a step-by-step guide:

- Initialization: Start by turning on the machine using the main power switch. Ensure that all safety guards are in place and that the machine is in a stable position.

- Setting Parameters: Using the touch screen interface, input the desired parameters such as can size, filling volume, and seaming specifications.

- Loading: Ensure that the cans and the product to be filled are ready. Load the cans onto the conveyor belt and ensure the filling reservoir is filled with the product.

- Starting the Process: Once everything is set, press the ‘Start’ button. The machine will automatically fill and seam the cans as they move along the conveyor belt.

- Monitoring: Regularly check the machine’s operation. Look out for any inconsistencies in filling or seaming and make adjustments as necessary.

- Shutdown: Once the operation is complete, press the ‘Stop’ button and turn off the main power switch. Ensure to clean the machine components to maintain hygiene.

Why Choose PkgMach as Your Trusted Supplier?

In the vast sea of suppliers, PkgMach stands out as a beacon of reliability. Here’s why:

- Global Presence: Originating in China, PkgMach has expanded its horizons globally, catering to businesses worldwide.

- Product Diversity: From salt packaging machines to rotary capping machines, PkgMach offers a diverse range of products, ensuring businesses find exactly what they need.

- Unwavering Commitment: PkgMach’s dedication goes beyond just selling machines. They are committed to ensuring businesses thrive with the right packaging solutions.

Questions International Buyers Should Ask Chinese Suppliers

Engaging with international suppliers, especially from China, requires due diligence. Here are some pertinent questions buyers should consider:

- What customization options are available for the machine?

- What is the warranty period, and what does it cover?

- Are there any after-sales services or support provided?

- What are the shipping and delivery logistics?

- Can you provide references or testimonials from previous international clients?

Comparing Costs: Investing in Quality vs. Settling for Less

While cost is a significant factor in decision-making, it’s essential to look at the bigger picture. Investing in a high-quality machine might seem expensive initially, but the long-term benefits, such as reduced maintenance costs, increased efficiency, and consistent product quality, outweigh the initial investment. On the other hand, opting for cheaper alternatives might lead to frequent breakdowns, inconsistent product quality, and increased operational costs.

FAQ Tips about Automatic CAN Filling & Seaming Machine

- How does the machine ensure minimal oxygen exposure during canning?The machine is designed to purge cans with an inert gas before filling, reducing oxygen levels and ensuring product freshness.

- How does the seaming process work?The seaming process involves crimping the can’s lid onto the body, creating an airtight seal that preserves the product’s quality.

- What safety features are incorporated in the machine?The machine integrates multiple safety devices, ensuring both machine and operator safety during high-speed operations.

- How often should maintenance checks be conducted?Regular maintenance checks, ideally once a month, are recommended to ensure the machine’s optimal performance.

- Are there financing options available?Yes, many suppliers, including PkgMach, offer various financing options to ease the purchasing process.

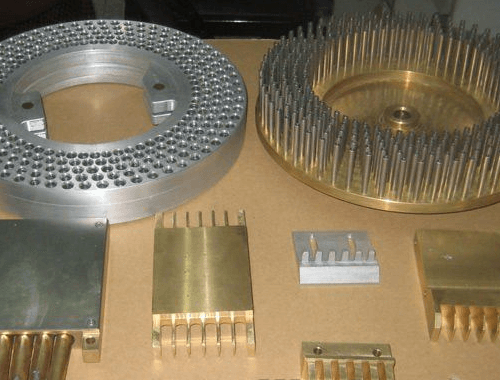

- What materials are used in the construction of the machine?The machine is primarily made from either SUS304 or SUS316L, ensuring durability and resistance against corrosion.

- How does the machine cater to different can sizes?The machine is designed to handle both slim CAN and stubby CAN, allowing businesses to customize their packaging based on product and market demand.

- Is there any training provided for operating the machine?Yes, suppliers typically offer comprehensive training sessions to ensure operators are well-versed with the machine’s functionalities.

- What is the average lifespan of the machine?With regular maintenance and proper care, the machine can efficiently operate for several years, offering a good return on investment.

- How does the machine ensure consistent filling and seaming?Advanced sensors and PLC controls are integrated into the machine, ensuring consistent filling volumes and precise seaming for every can.

I hope these FAQs provide clarity on the automatic canning machine. If you have any more questions or need further elaboration on any point, please let me know!