Impulse sealing machines have revolutionized the packaging industry, offering a fast, efficient, and reliable method to seal a wide range of thermosealable materials. Whether you're in the food industry, retail, or any sector requiring secure packaging, these machines are indispensable.

Overview of Impulse Sealing Machines

Impulse sealing machines utilize a rapid electrical current to generate heat, sealing materials within mere seconds. Unlike continuous heat sealers, they only use power when the sealing process is active, making them energy-efficient and safe.

PkgMach.com: Your Go-To Source for Packaging Solutions

PkgMach.com, a renowned name in the packaging industry, offers a plethora of solutions tailored to your needs. From impulse sealing machines to comprehensive packaging systems, their expertise ensures you get the best in the market.

Why Choose PkgMach.com?

- Experience: Years of industry presence ensures you get tried and tested products.

- Quality: Every product undergoes rigorous quality checks.

- Custom Solutions: Tailored solutions to fit unique business needs.

- After-Sales Support: A dedicated team to assist you post-purchase.

Types and Applications of Impulse Sealing Machines

Manual Impulse Sealers: Ideal for small-scale operations, these are operated by hand and are perfect for sealing bags of varying sizes.

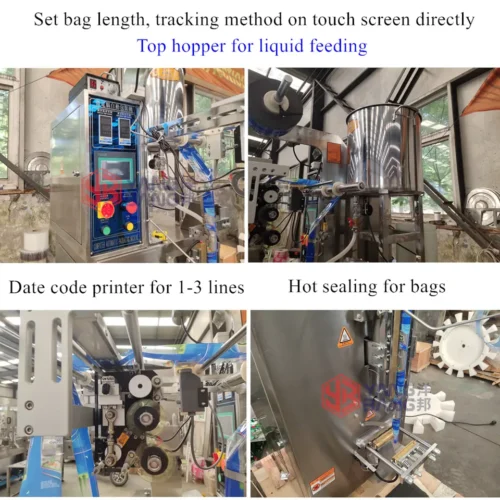

Automatic Impulse Sealers: Suited for larger operations, they offer consistent seals and can be integrated into automated packaging lines.

Applications:

- Food Packaging: Ensure food items remain fresh and free from contaminants.

- Retail: Seal products securely before they hit the shelves.

- Medical: Seal medical equipment and supplies, ensuring sterility.

Production Process in Chinese Factories

China, a global manufacturing hub, ensures that impulse sealing machines are produced with precision and quality.

Design Phase: Engineers conceptualize the machine, ensuring it meets global standards.

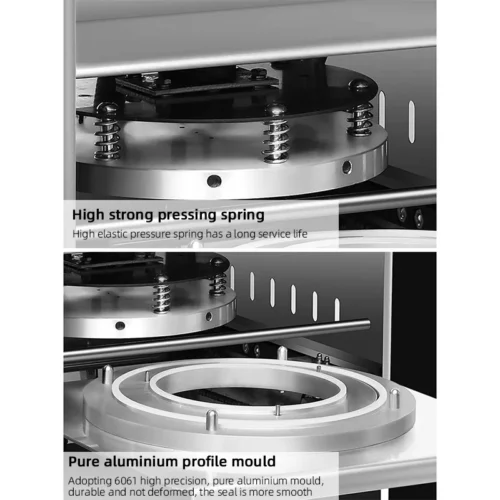

Material Procurement: High-quality metals and components are sourced to build the machine.

Assembly: Skilled technicians assemble the machine, ensuring every component is perfectly aligned.

Quality Checks: Rigorous testing ensures the machine operates optimally.

User Guide: Operating an Impulse Sealing Machine

Safety Precautions: Always ensure the machine is placed on a stable surface. Keep away from water and ensure your hands are dry during operation.

Operation Steps:

- Setup: Plug in the machine and adjust the sealing time based on the material thickness.

- Placement: Place the open end of the bag on the sealing platform.

- Sealing: Press down the handle and release once the sealing process is complete.

Questions International Buyers Should Ask Chinese Suppliers

- Certifications: Does the machine adhere to international safety and quality standards?

- Warranty: What kind of warranty do you offer on the impulse sealing machine?

- Bulk Pricing: Do you offer discounts on bulk purchases?

- Customization: Can modifications be made to the machine based on specific requirements?

- Shipping: How do you handle international shipping, and what are the associated costs?

FAQ Tips

Q1: How does an impulse sealing machine differ from a continuous heat sealer?

Answer: Impulse sealers use electricity only during the sealing process, making them energy-efficient, while continuous heat sealers maintain constant heat.

Q2: Can impulse sealing machines seal all types of plastic bags?

Answer: They can seal most thermosealable materials, but it's essential to check the machine's specifications for specific material compatibility.

Q3: How long does the sealing process take?

Answer: Typically, the sealing process takes only a few seconds, depending on the material's thickness.

Q4: How energy-efficient are impulse sealing machines?

Answer: Impulse sealers are highly energy-efficient as they only consume power during the sealing process, unlike continuous sealers that maintain constant heat.

Q5: What's the average lifespan of an impulse sealing machine?

Answer: With proper maintenance and care, an impulse sealing machine can last for several years, depending on its usage frequency.

Q6: How do I ensure the best sealing results?

Answer: Regularly clean the sealing area, ensure the machine is calibrated correctly, and choose the right sealing time based on the material thickness.

Cost and Pricing Dynamics

When considering the purchase of an impulse sealing machine, understanding the cost and pricing dynamics is crucial. Here's what potential buyers should know:

- Material Costs: The quality of materials used in the machine directly impacts its price. High-grade metals and components may raise the machine's cost but ensure longevity and optimal performance.

- Manufacturing Process: Advanced manufacturing processes, which ensure precision and quality, can also influence the machine's price.

- Brand Reputation: Established brands, known for quality and reliability, might price their products higher due to the trust they've built in the market.

- Customization: Any customization or specific modifications can affect the final price of the machine.

- After-Sales Services: Machines that come with extended warranties, maintenance services, or training might be priced slightly higher but offer long-term benefits.

Recommendations

Impulse sealing machines are a game-changer in the packaging industry. Their efficiency, reliability, and ease of use make them a valuable asset for businesses of all sizes. When considering a purchase:

- Assess Your Needs: Determine the scale of your operations and the type of materials you'll be sealing.

- Budget Considerations: While it's essential to stay within budget, don't compromise on quality. A slightly higher initial investment can offer better long-term returns.

- Supplier Reputation: Always choose a trusted supplier like PkgMach.com, known for quality and reliability.