Sure! Here is a list of FAQs with answers for manufacturing a water filling machine at SourcifyChina factory:

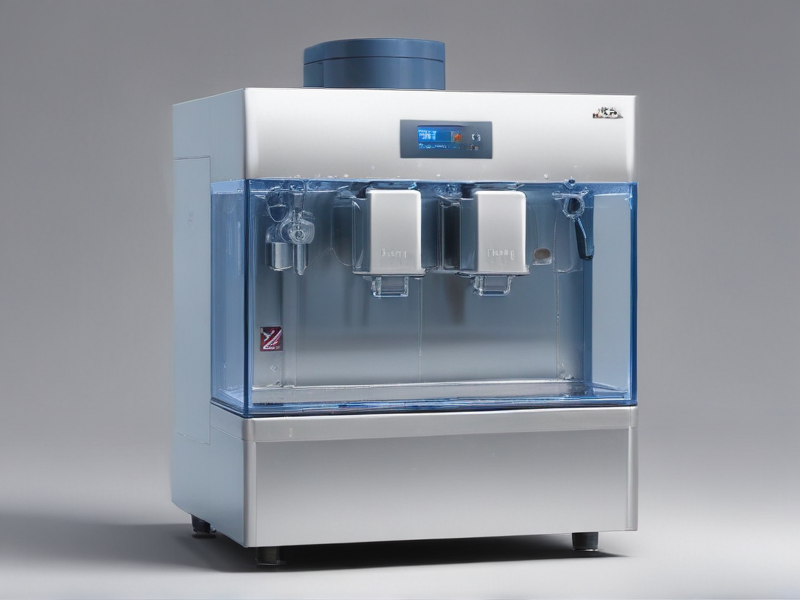

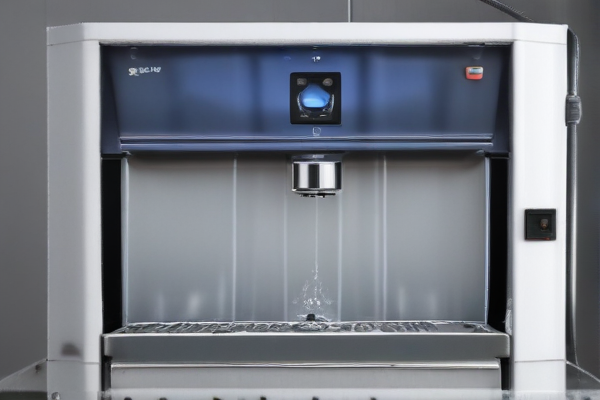

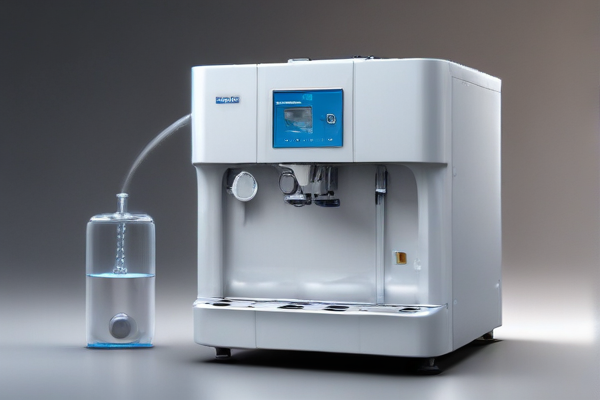

Q: What types of water filling machines does SourcifyChina manufacture?

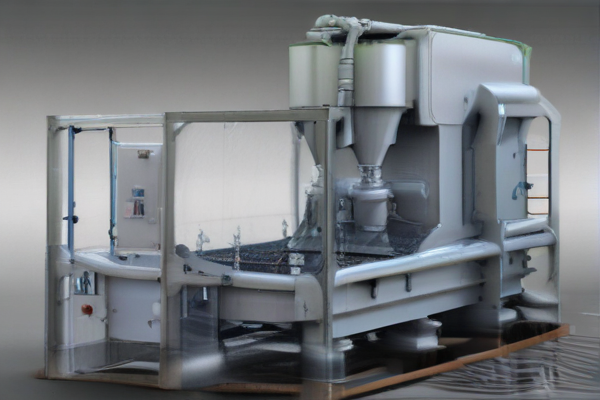

A: SourcifyChina manufactures various types of water filling machines, including automatic, semi-automatic, and manual models, designed to handle different bottle sizes and production capacities.

Q: How does SourcifyChina ensure the quality of its water filling machines?

A: Quality is ensured through rigorous quality control processes, including material inspection, assembly monitoring, and performance testing. Each machine undergoes thorough checks to meet international standards.

Q: Can SourcifyChina customize water filling machines to specific requirements?

A: Yes, SourcifyChina offers customized solutions tailored to meet individual client specifications, including machine design, capacity, and additional functionalities to suit specific production needs.

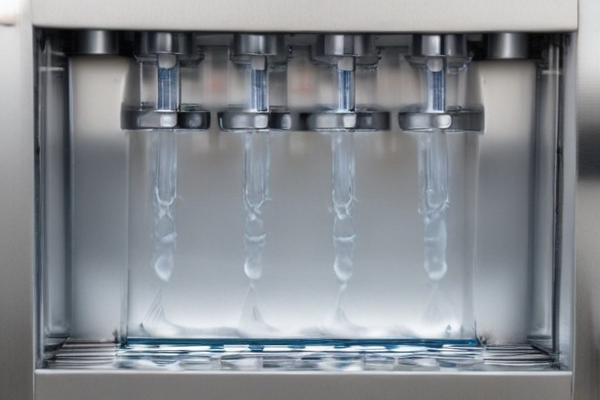

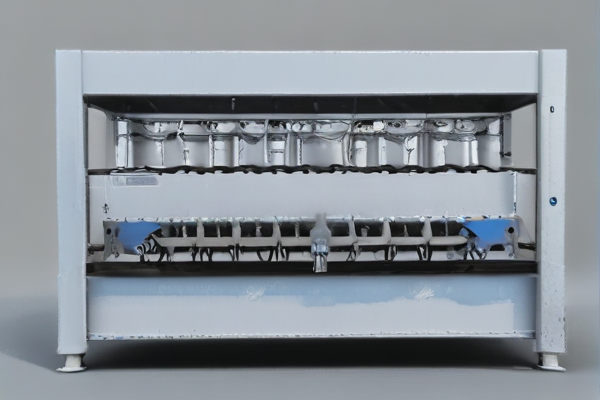

Q: What types of materials are used in the construction of the machines?

A: SourcifyChina primarily uses high-grade stainless steel and food-grade materials to ensure durability, hygiene, and compliance with industry standards for water bottling.

Q: What is the production lead time for a water filling machine?

A: The typical production lead time ranges from 4 to 8 weeks, depending on the complexity and customization of the machine. SourcifyChina will provide a more detailed timeline during the consultation phase.

Q: What after-sales support does SourcifyChina provide?

A: SourcifyChina offers comprehensive after-sales support, including installation guidance, maintenance services, spare parts supply, and technical support to ensure optimal machine performance.

Q: How energy-efficient are SourcifyChina’s water filling machines?

A: The machines are designed with energy efficiency in mind, incorporating advanced technologies that minimize energy consumption while maximizing output, thereby reducing operational costs.

Q: Are there any safety features included in the water filling machines?

A: Yes, the machines include multiple safety features such as emergency stop buttons, protective covers, and automated shutdown systems to ensure operator safety and prevent equipment damage.

Q: What certifications do water filling machines from SourcifyChina hold?

A: SourcifyChina’s water filling machines typically hold certifications such as ISO, CE, and other relevant international standards, ensuring compliance with global regulations.

Q: How can I place an order or request a quotation from SourcifyChina?