Water sachet packing machines are versatile devices designed to package water in small, sealed pouches. They are available in various types, which mainly differ in speed, automation, and additional features offered.

– Manual Water Sachet Packing Machines

– Require human operation for filling and sealing.

– Suitable for small-scale operations.

– Lower cost, but slower speed.

– Semi-Automatic Water Sachet Packing Machines

– Partially automate the filling or sealing process.

– Balance between cost and efficiency.

– Suitable for mid-sized businesses.

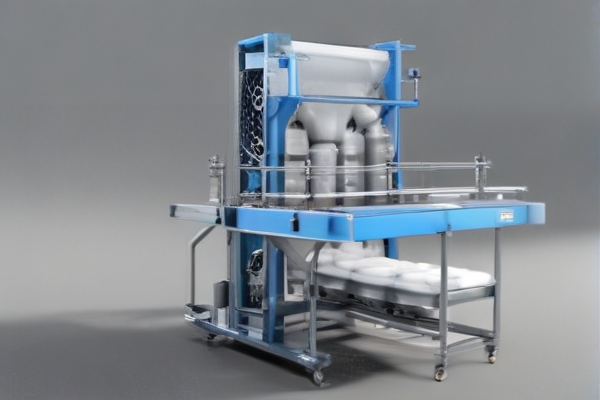

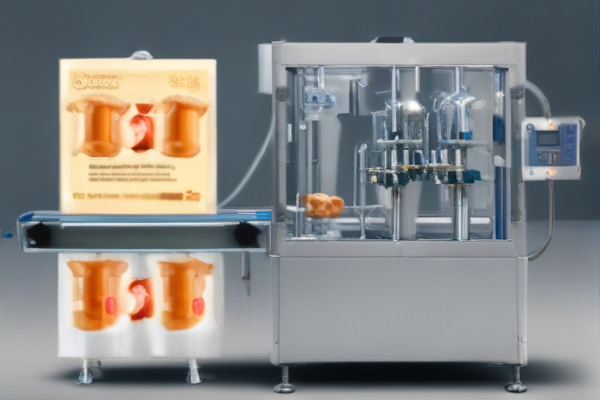

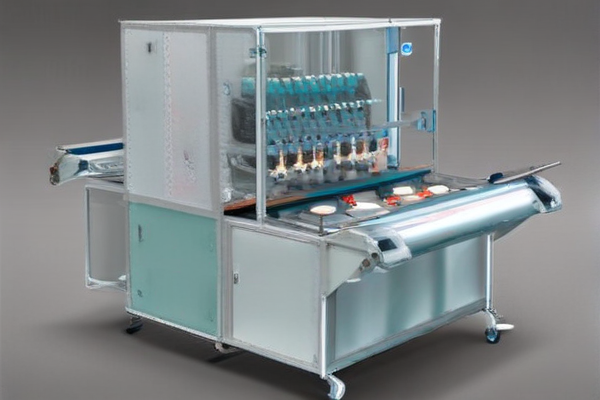

– Fully Automatic Water Sachet Packing Machines

– Fully automate the filling, sealing, and packaging process.

– Ideal for large-scale production.

– Higher investment but greater output and consistency.

– Continuous Motion Machines

– Operate without stopping, ensuring a high-speed production.

– Used for high-demand environments.

– Intermittent Motion Machines

– Operate in a start-stop fashion, suitable for moderate speeds.

– Better for medium-scale production.

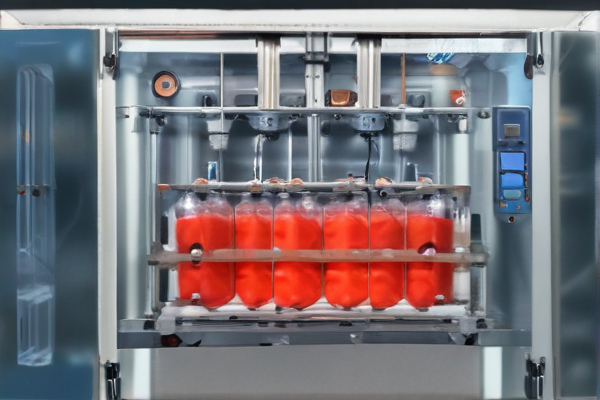

– Vertical Form Fill Seal (VFFS) Machines

– Pack water in vertical-oriented sachets.

– Compact and efficient layout.

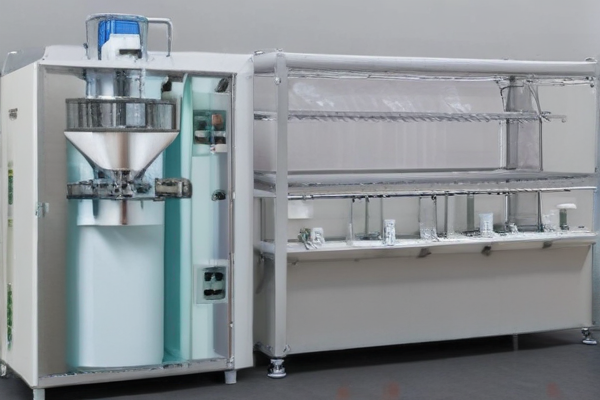

– Horizontal Form Fill Seal (HFFS) Machines

– Pack water in horizontally-oriented sachets.

– Often used for varied pouch shapes.

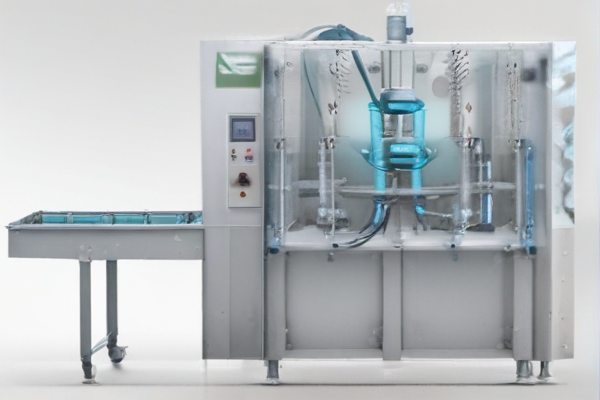

– Features and Options

– Material Compatibility: Can handle different packaging materials like polyethylene and laminated films.

– Capacity and Speed: Configurations range from 500 to several thousand sachets per hour.

– Optional Add-ons: Date printing, sterilization features, and custom shapes.

– Operating Modes: Manual, semi-automatic, and fully automatic.

– Maintenance and Durability: Stainless steel models for better life-span and hygiene.

Choosing the right water sachet packing machine depends on the production scale, budget, and specific packaging requirements.