Sure, here’s a list of frequently asked questions (FAQ) with answers regarding sourcing a glass bottle water filling machine from SourcifyChina factory:

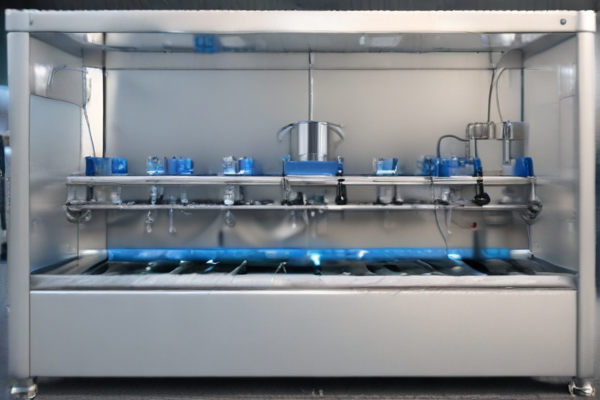

1. What is the production capacity of the glass bottle water filling machines?

SourcifyChina offers machines with various production capacities, ranging from 1,000 to 36,000 bottles per hour. You can select a model based on your production needs.

2. Can the machine fill bottles of different sizes?

Yes, the machines can be easily adjusted to accommodate different bottle sizes, making them versatile for various production requirements.

3. What type of warranty and after-sales support is provided?

SourcifyChina provides a standard one-year warranty on all machines. They also offer comprehensive after-sales support, including troubleshooting, remote assistance, and the availability of spare parts.

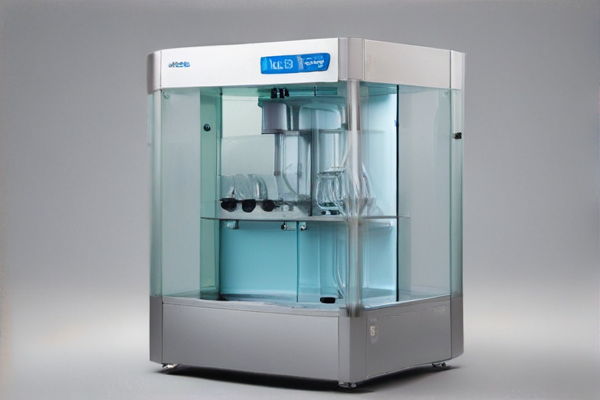

4. Are the machines easy to operate and maintain?

Indeed, the machines are designed for user-friendly operation and ease of maintenance. Detailed manuals and training materials are provided to ensure smooth operation and minimal downtime.

5. How long does it take to deliver the machine once an order is placed?

Delivery times can vary, but typically, it takes 4 to 6 weeks from the order confirmation to dispatch. Exact timelines can be discussed based on specific order requirements.

6. What are the power requirements for the glass bottle water filling machines?

The machines generally require a standard power supply of 380V/50Hz, but customizations can be made according to specific regional power standards.

7. Is installation and commissioning included in the purchase?

Installation and commissioning services are available upon request. The cost and availability of these services can be included in the purchase agreement.

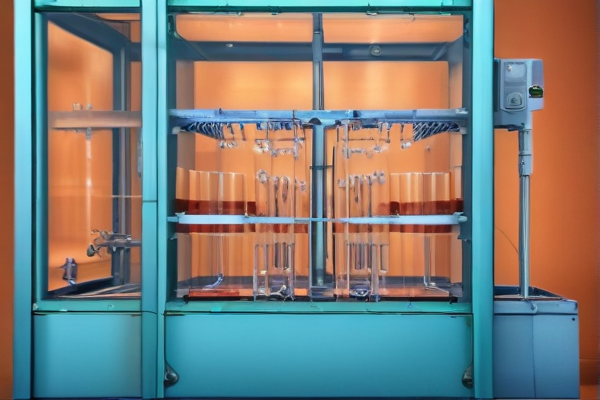

8. Can the filling machine integrate with existing production lines?

Yes, SourcifyChina can customize the machines to seamlessly integrate with your existing production lines, ensuring a smooth and efficient operation.

9. What is the payment process for purchasing the machine?

The usual payment terms are 30% advance payment upon order confirmation and the remaining 70% before shipment. Other terms can also be negotiated based on specific requirements.

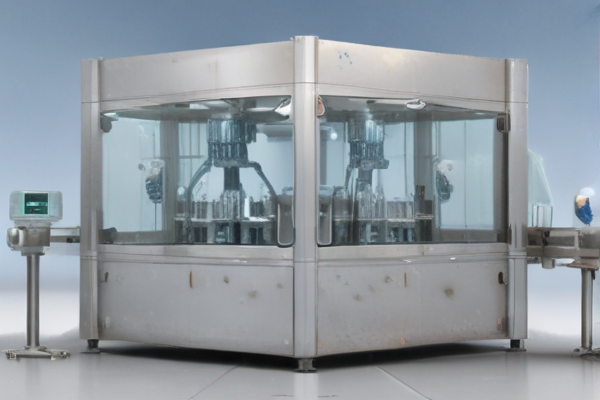

10. Can I visit the factory for a demonstration before purchasing?

Absolutely, SourcifyChina welcomes potential clients to visit their factory for a live demonstration and better understanding of the machine’s capabilities and quality.

This FAQ provides answers to common questions, helping you make an informed decision when sourcing a glass bottle water filling machine from SourcifyChina factory.