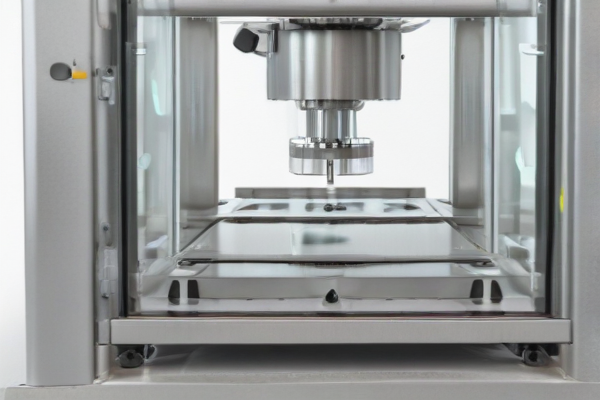

Vial filling machines are essential in pharmaceutical and biotech industries for accurately dispensing liquids or powders into vials. These machines come in various types, including automatic, semi-automatic, and manual, each offering specific attributes.

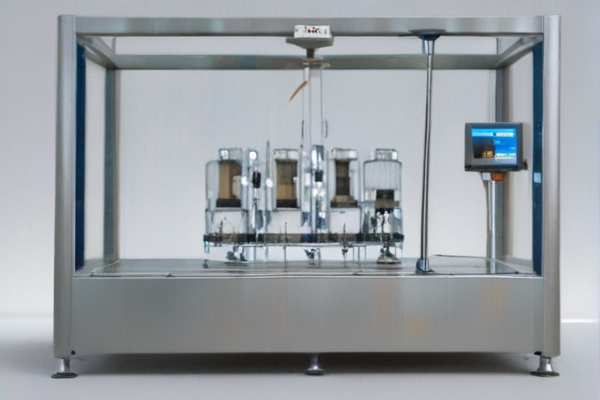

– Automatic Vial Filling Machines:

– High-speed production

– Integration with capping and labeling systems

– Suitable for large-scale manufacturing

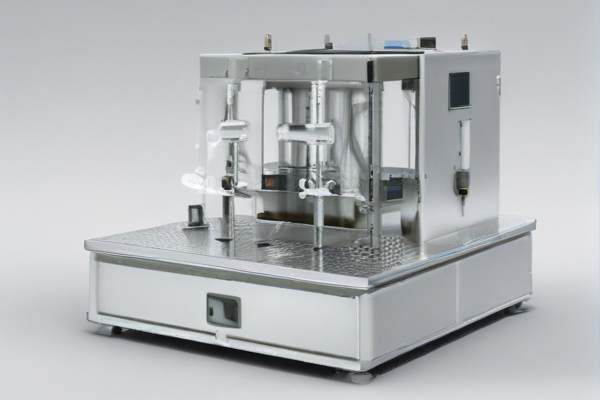

– Semi-Automatic Vial Filling Machines:

– Moderate speed

– Requires manual intervention

– Flexible for different batch sizes

– Manual Vial Filling Machines:

– Low-speed production

– Ideal for small batches or lab use

– Cost-effective

– Liquid Vial Filling Machines:

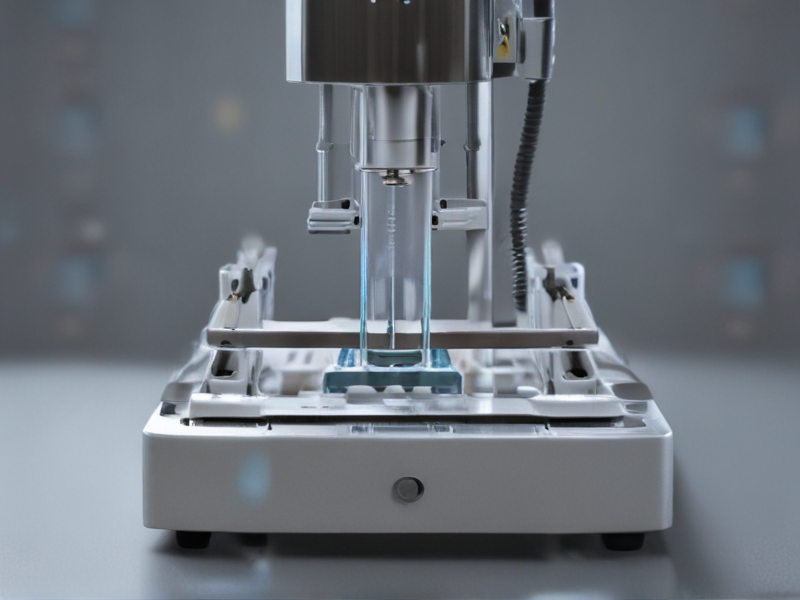

– Precision liquid dispensing

– Employed for vaccines, serums, and other liquid medications

– Powder Vial Filling Machines:

– Designed specifically for handling powder forms

– Used for antibiotics, freeze-dried powders

– Single-head Vial Filling Machines:

– Suitable for small-scale production

– Lower throughput

– Multi-head Vial Filling Machines:

– High-efficiency with multiple filling heads

– Increased production rates

– Inline Vial Filling Machines:

– Conveyor-based system

– Ideal for continuous production lines

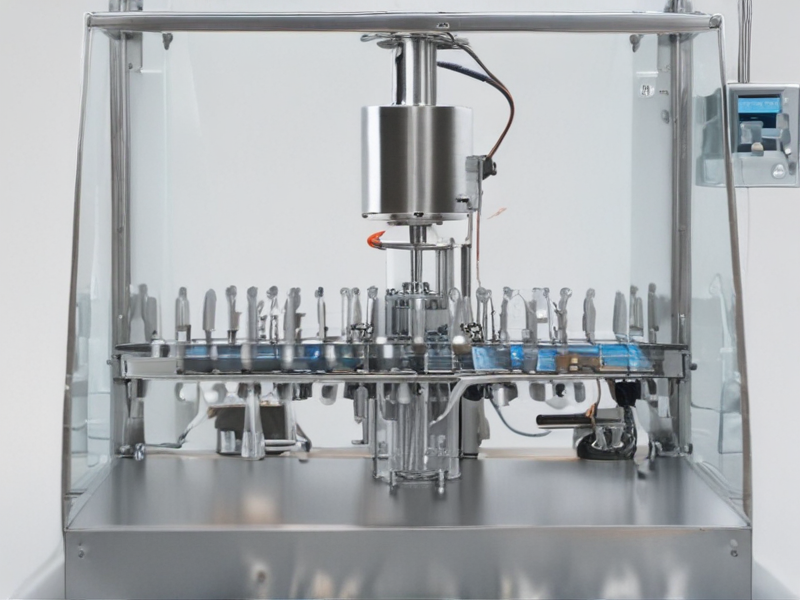

– Rotary Vial Filling Machines:

– Rotary table for high-speed filling

– Optimized for high-volume operations

– Aseptic Vial Filling Machines:

– For sterile and contamination-free filling

– Used in the production of injectable medications

– Customization Options:

– Adjustable filling volumes

– Integration with different vial sizes

– Compatible with various closure types (screw caps, rubber stoppers)

Selecting the right vial filling machine depends on production scale, material type, and specific requirements of the pharmaceutical product. Various options ensure efficiency, precision, and compliance with regulatory standards.