Sure! Here is a list of frequently asked questions (FAQ) regarding the quality of alcohol filling machines manufactured by SourcifyChina factory:

1. What types of alcohol filling machines does SourcifyChina manufacture?

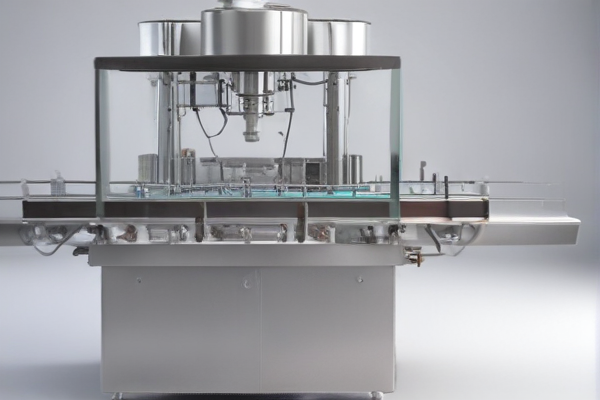

SourcifyChina manufactures a wide range of alcohol filling machines, including automatic, semi-automatic, and manual filling machines, suitable for various bottle sizes and types. They are designed for efficiency, precision, and reliability.

2. Are the machines made from high-quality materials?

Yes, SourcifyChina ensures that all alcohol filling machines are constructed from high-grade stainless steel and other durable materials to meet industry standards and provide long-lasting performance.

3. Do your machines adhere to industry standards and certifications?

Absolutely. SourcifyChina’s alcohol filling machines comply with international standards such as ISO, CE, and GMP, ensuring they meet safety and quality criteria.

4. Can the machines handle different types of alcohol products?

Yes, the machines are versatile and can handle various types of alcohol, including spirits, wines, beers, and other liquid alcoholic beverages, with adjustments for viscosity and bottle types.

5. Do you offer customization options for the machines?

SourcifyChina offers customization services to meet specific production needs. This includes adapting the machine to different bottle shapes, sizes, and production capacities.

6. What kind of after-sales support do you provide?

SourcifyChina provides comprehensive after-sales support, including installation guidance, training, maintenance services, and technical assistance to ensure smooth operation of the machines.

7. How do you ensure the accuracy and precision of the filling machines?

Advanced technology and precise engineering are employed in the design and manufacturing process to ensure accurate filling volumes, minimal product waste, and high efficiency.

8. What is the lead time for manufacturing and delivery?

The lead time can vary based on order specifications and quantity, but generally, it ranges from 4-8 weeks for manufacturing and delivery.

9. Can I inspect the machines before purchase?

Yes, SourcifyChina welcomes potential customers to visit their facility to inspect machines and discuss specific requirements before making a purchase.

10. What warranties are offered for the alcohol filling machines?

SourcifyChina provides a standard one-year warranty on their alcohol filling machines, covering parts and labor, with options for extended warranties.