1. What is an auger filling machine?

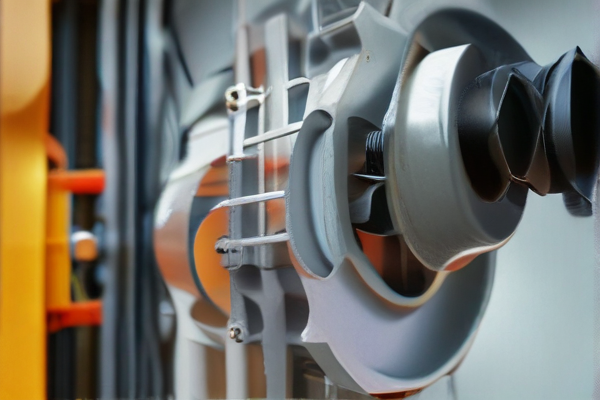

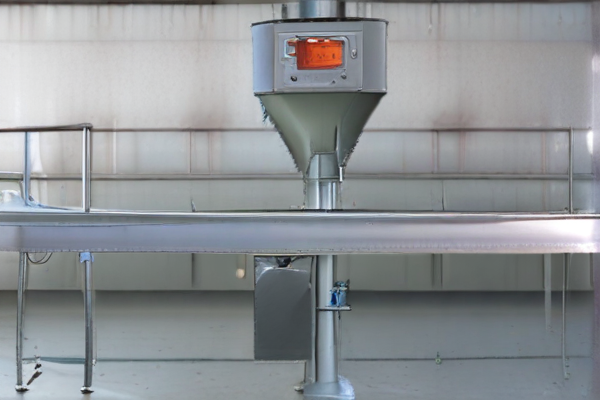

An auger filling machine is designed to dispense and fill powder and granular products into containers with precision, using a rotating screw mechanism known as an auger.

2. What materials can the auger filling machine handle?

The auger filling machine from SourcifyChina Factory can handle a wide range of materials, including but not limited to powders, granules, spices, flour, and coffee grounds.

3. What capacities are available for your auger filling machines?

We offer various capacities to suit different production needs, from small-scale operations to large industrial outputs.

4. How does SourcifyChina ensure the quality of its auger filling machines?

Quality is ensured through a rigorous manufacturing process, which includes the use of high-quality materials, compliance with international standards, and multiple quality control checks.

5. Are your machines customizable?

Yes, we provide customization options to meet specific requirements such as filling capacities, material types, and packaging integrations.

6. What kind of maintenance do these machines require?

Regular maintenance involves cleaning the auger and other parts in contact with the product, checking for wear and tear, and timely replacement of any worn-out components.

7. How do I install the auger filling machine?

Our machines come with detailed installation manuals, and we also offer remote assistance or on-site installation services if needed.

8. Can I integrate the auger filling machine with my existing production line?

Yes, our machines are designed for easy integration with existing production lines and compatible with various automation systems.

9. What after-sales services do you offer?

We offer comprehensive after-sales services, including technical support, spare parts supply, and machine maintenance programs.

10. What is the lead time for manufacturing and delivery?

The typical lead time is 4-6 weeks, depending on the level of customization required. We strive to deliver products as promptly as possible while ensuring top-notch quality.