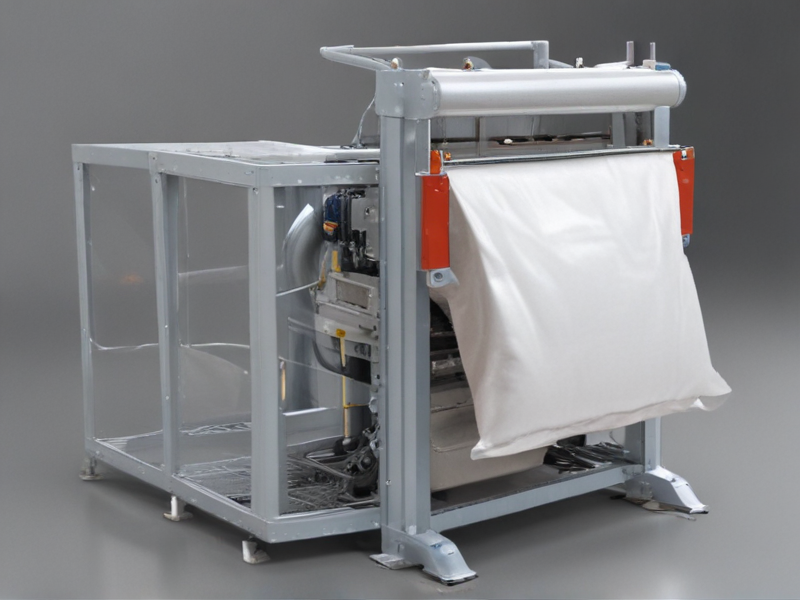

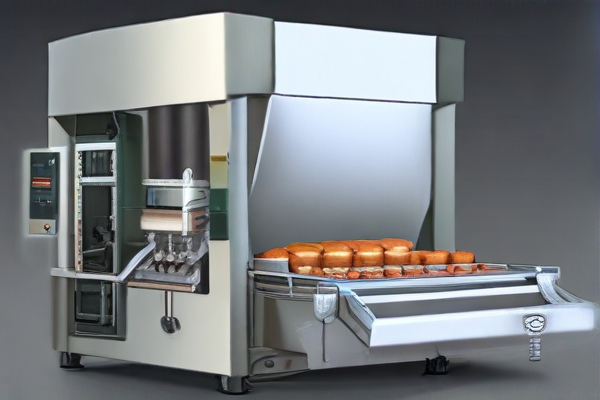

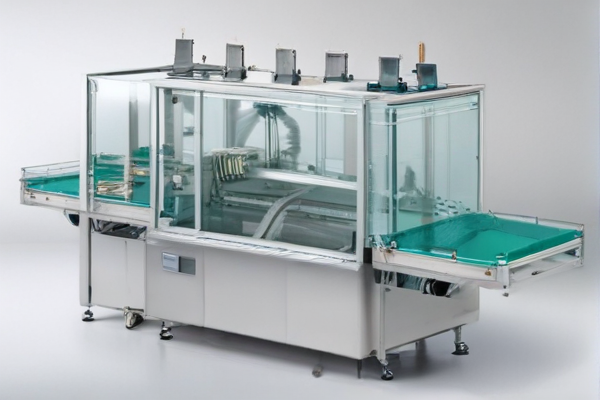

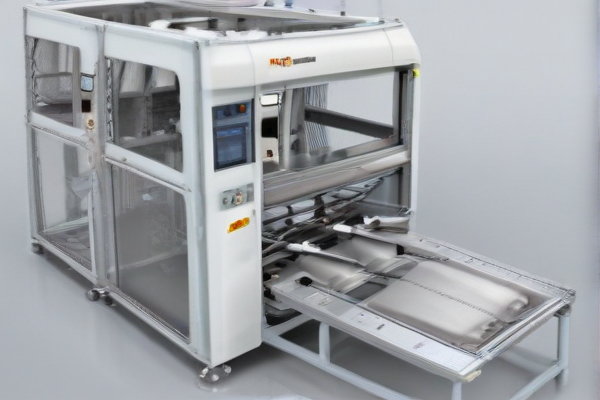

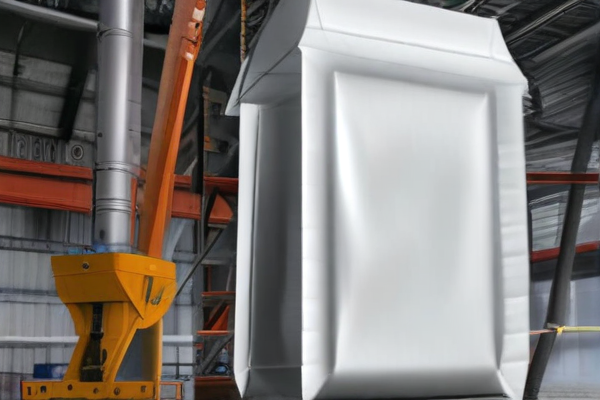

Auto bagging equipment is essential for companies seeking efficient, high-speed packaging solutions to enhance productivity and reduce labor costs. These machines can handle a variety of products, ensuring each item is securely bagged.

– Food Packaging: Ideal for packaging snacks, frozen foods, and fresh produce with speed and precision.

– Retail: Automates bagging for clothing, accessories, and other retail items, streamlining checkout processes.

– E-commerce: Enhances order fulfillment efficiency by accurately packing a wide range of products for shipping.

– Pharmaceuticals: Ensures hygienic and contamination-free packaging of medications and health products.

– Hardware and Industrial Parts: Suited for packaging nuts, bolts, and other small components, maintaining order and inventory control.

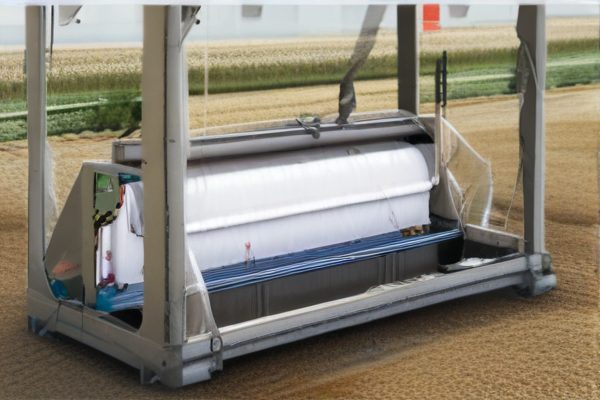

– Agricultural Products: Efficiently bags seeds, fertilizers, and other bulk agricultural items.

– Cosmetics and Toiletries: Provides secure packaging for creams, lotions, and other personal care products.

– Textiles: Packages various textile materials, ensuring they are kept clean and organized.

– Pet Products: Efficient for bagging pet food and accessory items, meeting hygiene standards.

– Automotive: Handles packaging of spare parts and accessories, preventing damage and loss.

– Medical Supplies: Critical for safely bagging medical devices, ensuring sterility and compliance with regulations.

– Construction Materials: Helps in packaging small construction materials like nails and screws efficiently.

– Electronics: Securely bags electronic components, protecting them from static and damage.

– Household Goods: Automates bagging of detergents, cleaners, and other household essentials.

– Toys and Games: Provides uniform packaging for toys, ensuring they are safely shipped.

– Stationery: Makes packaging of pens, paper, and other office supplies more efficient.

– Promotional Products: Streamlines packaging of promotional giveaways and corporate gifts.

By integrating auto bagging equipment, businesses can significantly enhance their operational efficiency, maintain high packaging standards, and improve overall productivity.