Frequently Asked Questions (FAQs)

Q1: What certifications does SourcifyChina factory have for manufacturing autobagger machines?

A1: SourcifyChina factory is ISO 9001 certified, ensuring compliance with international standards for quality management. Additionally, we hold CE certification, which guarantees that our autobagger machines meet European safety, health, and environmental protection requirements.

Q2: How can I ensure the quality of autobagger machines from SourcifyChina?

A2: Our quality assurance process includes multiple inspections at various stages of manufacturing. Each machine undergoes rigorous testing before leaving our factory. Customers can also request third-party inspections to verify quality.

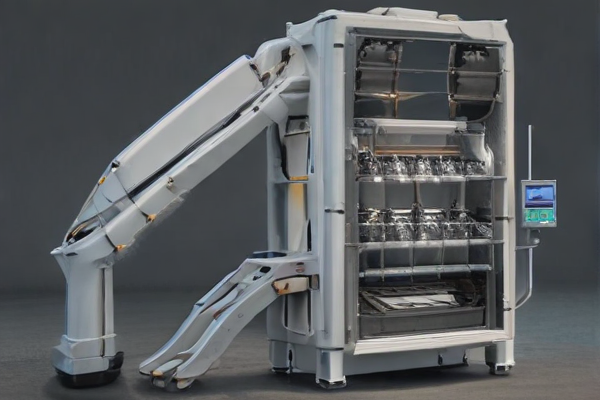

Q3: What materials are used in the production of your autobagger machines?

A3: We use high-quality, durable materials such as stainless steel and industrial-grade plastics. All components are sourced from reputable suppliers, ensuring longevity and reliability of the machines.

Q4: Can SourcifyChina factory customize autobagger machines to specific requirements?

A4: Yes, we offer customization services. Our engineering team works closely with clients to design and manufacture autobagger machines that meet specific needs, whether it’s size, functionality, or integration with existing systems.

Q5: What is the typical lead time for an order?

A5: The lead time ranges from 4 to 8 weeks, depending on the complexity and customization requirements. We provide a detailed timeline at the outset of the project to ensure transparency.

Q6: What kind of after-sales support does SourcifyChina provide?

A6: Our after-sales support includes a comprehensive warranty, technical support, and maintenance services. We offer online and on-site assistance to resolve any issues promptly.

Q7: How do I place an order with SourcifyChina factory?

A7: Orders can be placed through our website, via email, or by contacting our sales team directly. We provide a streamlined process to facilitate quick and easy ordering.

Q8: What payment terms do you offer?

A8: We offer flexible payment terms, including T/T (telegraphic transfer), L/C (letter of credit), and other mutually agreed-upon methods. Details are discussed during the quotation process.

Q9: Do you provide training for the operation and maintenance of autobagger machines?

A9: Yes, we provide comprehensive training sessions conducted by our expert technicians, either on-site or through online modules, to ensure your team is proficient in operating and maintaining the machines.