Sure, here’s a concise list of Frequently Asked Questions (FAQ) with answers for sourcing automated bagging systems from a SourcifyChina factory:

Q: What is the minimum order quantity (MOQ) for automated bagging systems?

A: The minimum order quantity varies by model and customization requirements. Typically, the MOQ is one unit for standard models.

Q: How long is the lead time for production and delivery?

A: Lead time usually ranges from 30-60 days, depending on the complexity of the system and order volume. Shipping time depends on the destination and chosen logistics method.

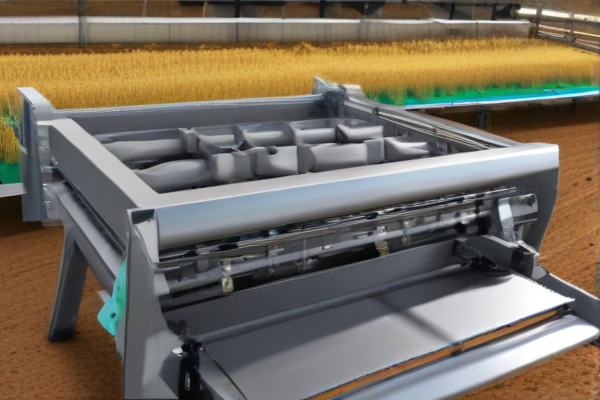

Q: Are customization options available?

A: Yes, SourcifyChina offers various customization options, including specific bagging speeds, bag sizes, and integration with existing production lines.

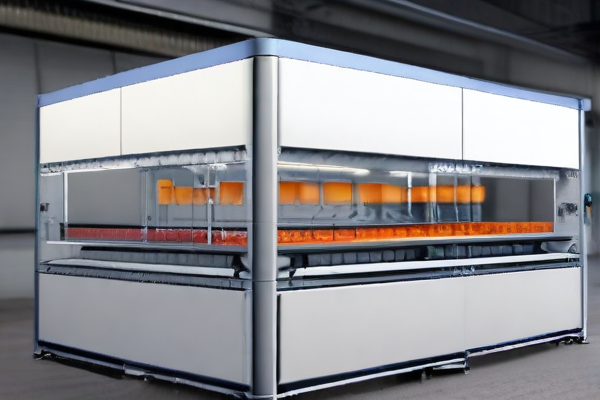

Q: What types of bags can these systems handle?

A: Automated bagging systems can handle various bag types, including polyethylene, paper, and laminated bags, suitable for products like grains, powders, and small parts.

Q: What is the warranty period provided?

A: SourcifyChina provides a standard warranty of 12-24 months, covering parts and labor. Extended warranties are available upon request.

Q: Are training and installation services included?

A: On-site installation and training services are available. The cost can be included in the package or quoted separately, depending on location and service scope.

Q: How do I get after-sales support and spare parts?

A: After-sales support is available via phone, email, or online chat. Spare parts can be ordered directly from SourcifyChina and are typically shipped within a few days.

Q: What are the payment terms?

A: Common payment terms are T/T (Telegraphic Transfer), with a deposit required upfront and the balance payable before shipment. Other payment options can be discussed during negotiations.

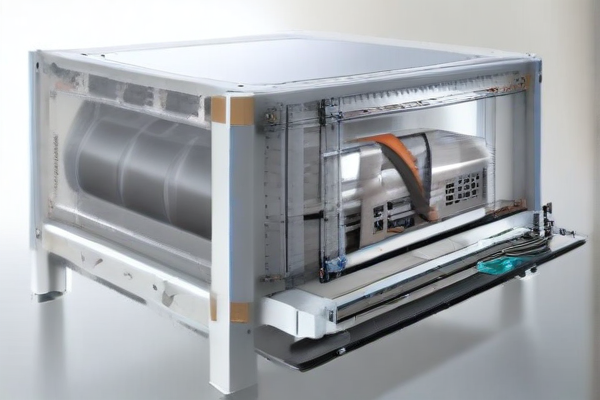

Q: How can I ensure the quality of the automated bagging system?

A: SourcifyChina adheres to ISO quality standards and conducts rigorous testing on all products. Factory audits and third-party inspections can also be arranged.

Q: Can I visit the factory for a tour or inspection?

A: Yes, factory visits are welcomed. Please schedule an appointment in advance to ensure your requirements are adequately addressed during the visit.

Feel free to reach out to SourcifyChina’s customer service for any questions not covered in this FAQ.