Sure, here are some frequently asked questions (FAQs) with their answers regarding manufacturing automated pre-roll machines with quality work from the SourcifyChina factory.

Q1: What types of pre-roll machines do you manufacture?

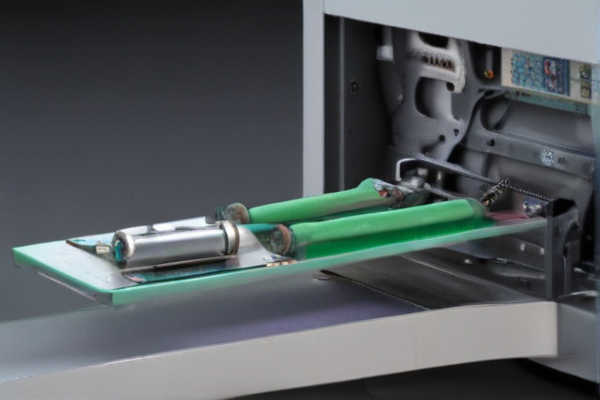

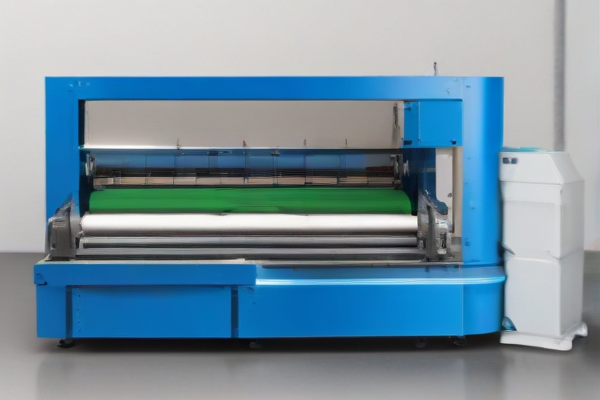

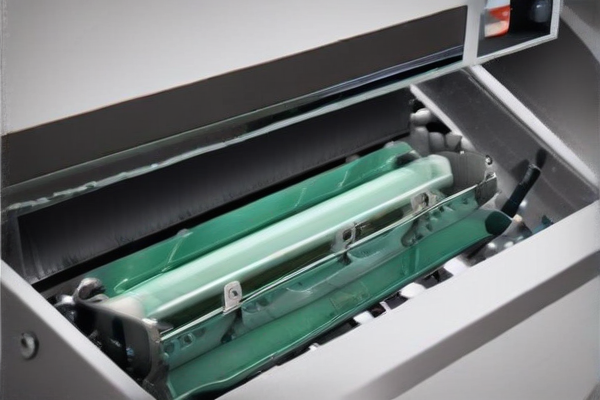

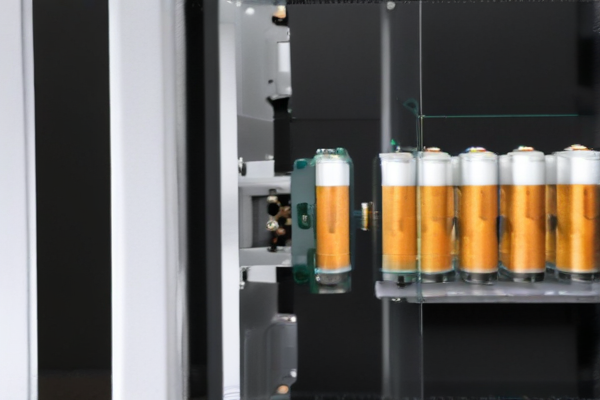

A1: We specialize in manufacturing various types of automated pre-roll machines, including cone fillers, joint rollers, and pre-roll multipackers. Each machine is designed to meet different production scale needs, from small batches to large-scale industrial output.

Q2: What sets SourcifyChina’s pre-roll machines apart from others?

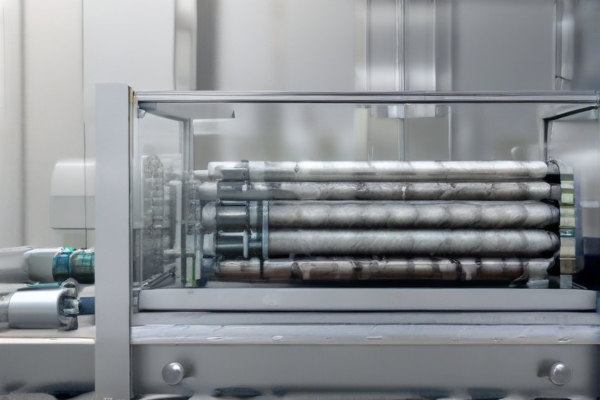

A2: SourcifyChina’s pre-roll machines are known for their precision, durability, and efficiency. We use high-quality materials and advanced technology to ensure consistent performance. Our machines are also equipped with user-friendly interfaces for easy operation and maintenance.

Q3: How do you ensure the quality of your machines?

A3: Quality is paramount at SourcifyChina. We implement rigorous quality control procedures, including thorough testing at each manufacturing stage. All machines undergo final performance testing to ensure they meet international standards before shipment.

Q4: Can you customize machines according to specific requirements?

A4: Yes, we offer customization services to meet specific client needs. Whether it’s adjusting machine capacity, integrating specific technology, or adding particular features, our engineering team works closely with clients to deliver tailored solutions.

Q5: What is the lead time for manufacturing and delivery?

A5: Lead time varies depending on the machine type and custom requirements. On average, standard models are ready within 4-6 weeks, while customized machines may take longer. We ensure timely delivery through a well-organized logistics network.

Q6: Do you provide after-sales support?

A6: Absolutely. Our commitment extends beyond delivery. We offer comprehensive after-sales support, including installation guidance, training, troubleshooting, and maintenance services to ensure optimal machine performance.

Q7: How can I place an order or request a quote?

A7: You can place an order or request a quote by contacting our sales team via email, phone, or through our website’s contact form. Provide details on your requirements, and we will get back to you with an appropriate solution and pricing information.

Q8: Are your machines compliant with international safety standards?

A8: Yes, all our machines are designed and manufactured to comply with international safety standards, including CE and ISO certifications, ensuring they are safe to operate in various regulatory environments.