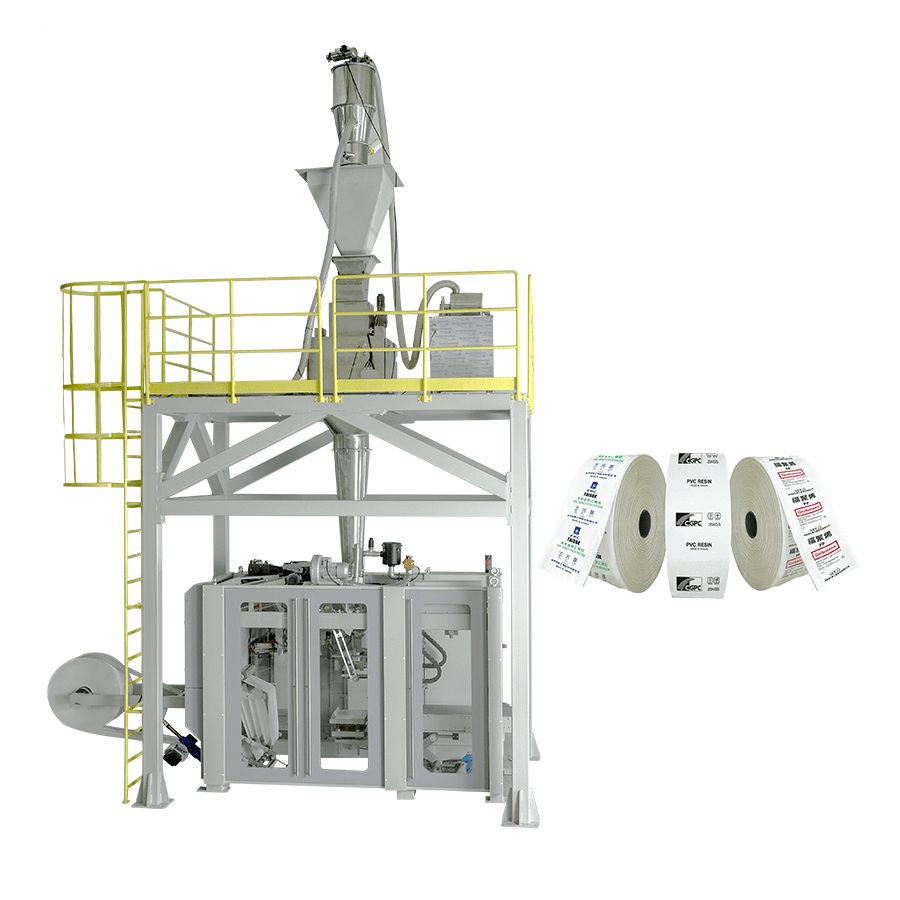

Sure, here is a succinct FAQ for the manufacturing of the “automatic bagger machine quality work from SourcifyChina factory”:

1. What is the standard lead time for manufacturing the automatic bagger machine at SourcifyChina factory?

The standard lead time is typically between 6 to 8 weeks, depending on the specific customization requirements and production schedule.

2. What certifications does the SourcifyChina factory hold for manufacturing automatic bagger machines?

Our factory holds ISO 9001:2015 certification, ensuring high standards in quality management systems. We also comply with CE certification for safety and quality requirements.

3. Can SourcifyChina customize the automatic bagger machine according to specific needs?

Yes, we offer customization services to tailor the machine according to specific dimensions, materials, and functionality to meet your operational requirements.

4. What materials are used in manufacturing the automatic bagger machines?

We use high-quality stainless steel and industrial-grade components to ensure durability, efficiency, and compliance with industrial standards.

5. How does SourcifyChina ensure quality control during manufacturing?

Quality control is a multi-step process including incoming material inspection, in-line production checks, and final machine testing. Our dedicated QC team performs rigorous tests to ensure each machine meets stringent quality standards.

6. What kind of after-sales service does SourcifyChina provide for the automatic bagger machines?

We offer a comprehensive after-sales service including technical support, maintenance, spare parts supply, and troubleshooting assistance for the lifespan of the machine.

7. Is onsite installation and training available?

Yes, we provide onsite installation and user training services to ensure your team can operate the machine efficiently and safely.

8. What are the payment terms offered by SourcifyChina for purchasing an automatic bagger machine?

Our standard payment terms are 30% deposit upon order confirmation and the remaining 70% before shipment. We also offer flexible payment terms based on mutual agreement.

9. Can SourcifyChina handle international shipping?

Yes, we have extensive experience in international shipping and can handle the entire logistics process, ensuring timely and efficient delivery to your location.

10. How energy-efficient are the automatic bagger machines from SourcifyChina?

Our machines are designed with energy efficiency in mind, using advanced technologies to reduce power consumption while maintaining high performance.

Each answer has been kept brief to align with the word limit constraint.