1. What types of automatic bagging equipment does SourcifyChina factory offer?

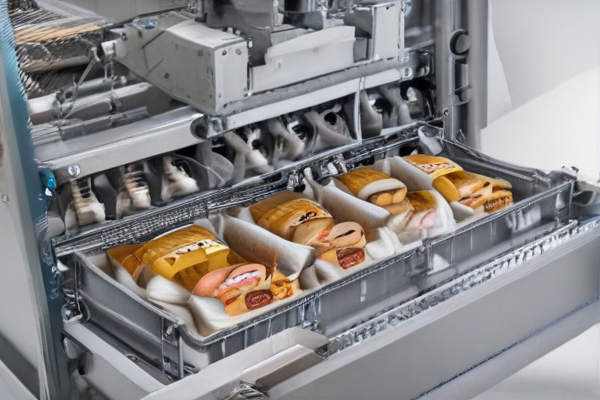

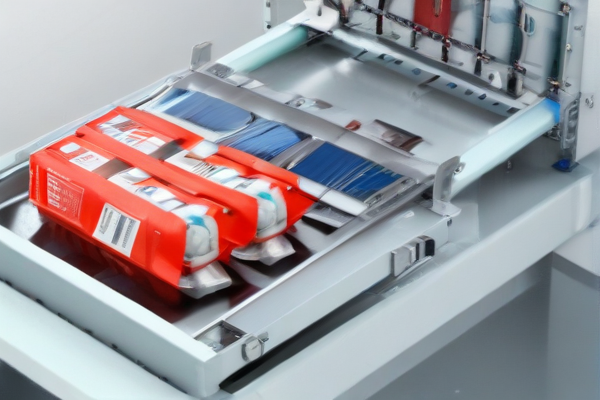

SourcifyChina provides a wide range of automatic bagging equipment, including vertical form fill seal machines, horizontal form fill seal machines, pre-made pouch packing machines, and more. Each type can handle a variety of products such as granules, powders, and liquids.

2. How does SourcifyChina ensure the quality of automatic bagging equipment?

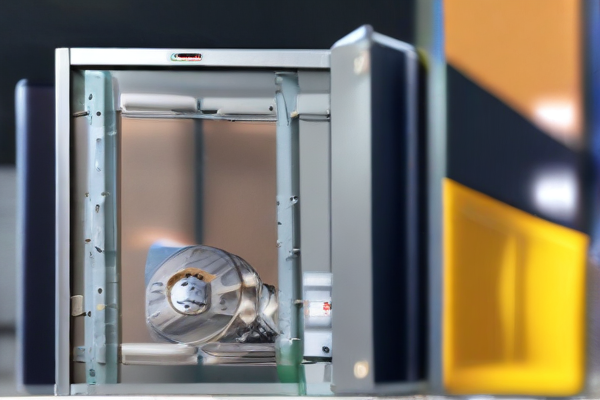

SourcifyChina implements strict quality control measures, including sourcing high-quality materials, thorough testing at various production stages, and final inspection before shipment. They are ISO certified and follow industry standards.

3. What industries can benefit from SourcifyChina’s automatic bagging equipment?

Their equipment is versatile and can be used in multiple industries including food and beverage, pharmaceuticals, chemicals, agriculture, and consumer goods. Customized solutions are available to meet specific industry needs.

4. Can SourcifyChina customize the automatic bagging equipment according to specific requirements?

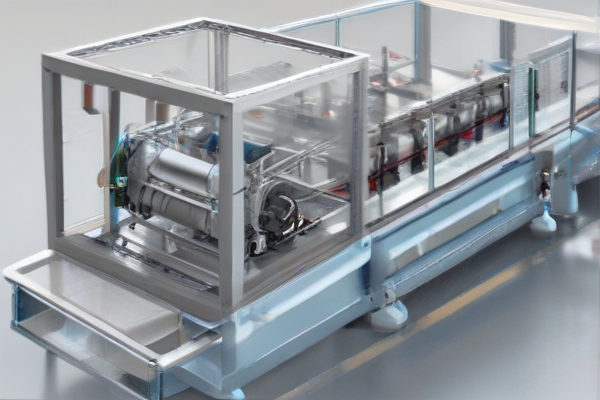

Yes, SourcifyChina offers customization options to tailor the equipment to your specific requirements, whether it’s machine size, output capacity, or integration with existing production lines.

5. What is the lead time for manufacturing and delivery?

The lead time varies based on customization and order size but typically ranges from 4 to 8 weeks. SourcifyChina aims to provide timely updates throughout the manufacturing process to ensure on-time delivery.

6. What after-sales support does SourcifyChina offer?

SourcifyChina provides comprehensive after-sales support, including installation guidance, user training, spare parts supply, and technical assistance. Their customer service team is available to resolve any issues promptly.

7. How energy-efficient is the automatic bagging equipment from SourcifyChina?

The equipment is designed to be energy-efficient, utilizing advanced technology that reduces power consumption and operational costs. This makes it an eco-friendly choice for modern manufacturing needs.

8. What safety features are integrated into SourcifyChina’s automatic bagging equipment?

Safety is a priority; hence, the equipment is equipped with features like emergency stop buttons, protective guards, and automated alarms to ensure the safety of operators and reduce the risk of accidents.

9. Are there any warranty and maintenance service options available?

SourcifyChina offers a standard warranty on their equipment and maintenance service plans to ensure long-term reliability. Details on warranty periods and service specifics can be provided upon request.