FAQ for Manufacturing Automatic Bagging Machine Quality Work from SourcifyChina Factory

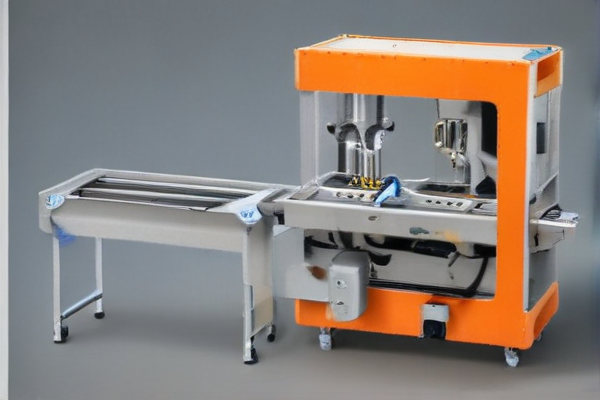

1. What types of automatic bagging machines does SourcifyChina manufacture?

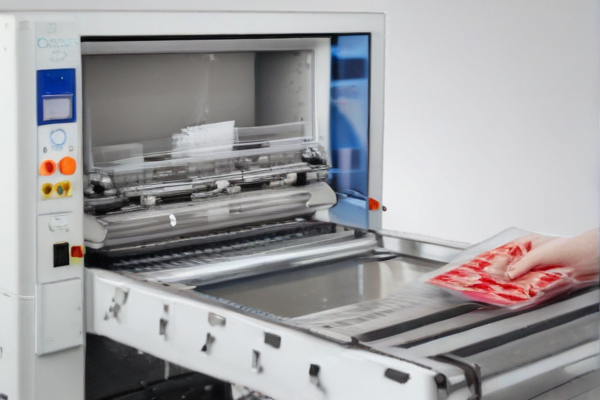

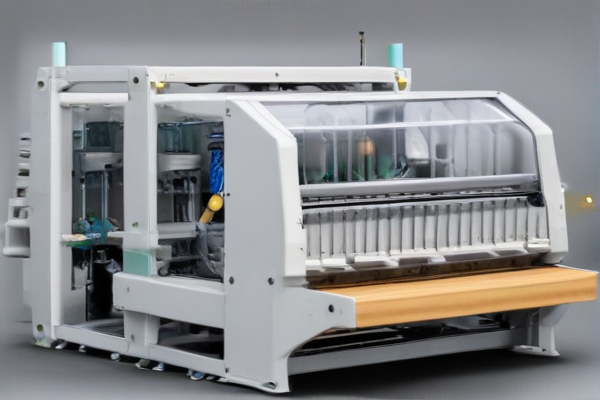

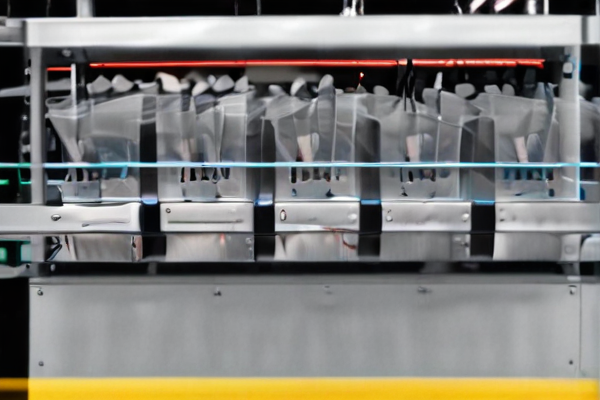

SourcifyChina specializes in producing various automatic bagging machines, including vertical form fill seal (VFFS) machines, horizontal form fill seal (HFFS) machines, pre-made pouch filling machines, and more. Each model can be customized based on specific industry needs.

2. What materials are compatible with SourcifyChina’s bagging machines?

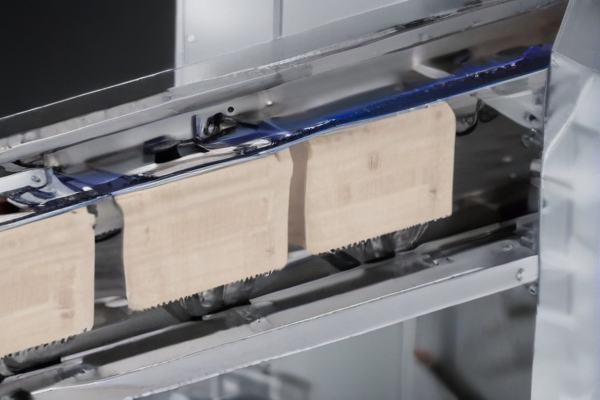

Our bagging machines work efficiently with a variety of bag materials, such as plastic, paper, laminated films, and aluminum foil. They cater to sectors like food, pharmaceuticals, chemicals, and more.

3. How do you ensure the quality of your automatic bagging machines?

We adhere to stringent quality control measures including rigorous in-house testing, compliance with international standards, and utilizing high-quality components. SourcifyChina maintains ISO certification and regularly updates our manufacturing protocols.

4. Can these machines handle various bag sizes and types?

Absolutely. Our automatic bagging machines are designed to be versatile and can handle multiple bag sizes and types, from small sachets to large bulk bags. Adjustable settings allow for optimal flexibility.

5. What is the lead time for manufacturing and delivery?

The lead time for manufacturing typically ranges from 6 to 12 weeks, depending on the complexity and customization required. Delivery times vary based on the destination but usually take an additional 1-4 weeks.

6. Do you offer after-sales support and training?

Yes, SourcifyChina provides comprehensive after-sales support including installation assistance, operator training, and 24/7 technical support to ensure smooth operation of your bagging machine.

7. Can SourcifyChina customize a machine based on unique requirements?

Yes, we offer customization services to tailor the machine according to your specific product and packaging needs. Our engineering team works closely with clients to develop custom solutions.

8. What is the warranty period for your machines?

Our automatic bagging machines come with a standard one-year warranty. Extended warranty options are also available upon request.

9. How can I place an order with SourcifyChina?

To place an order, you can contact our sales team through our official website or email. We will guide you through the ordering process and provide a detailed quotation based on your requirements.

10. What payment methods do you accept?