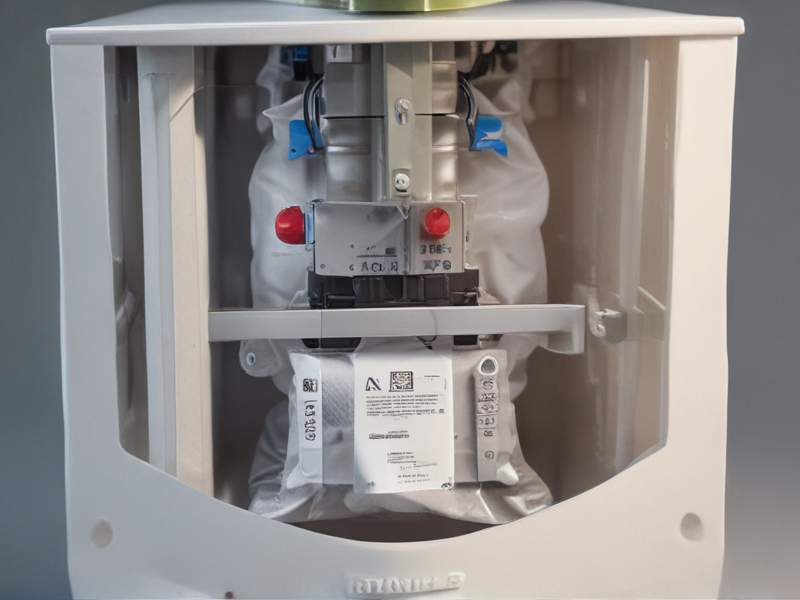

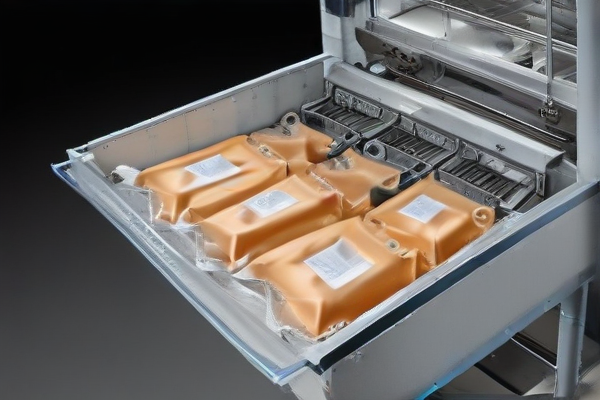

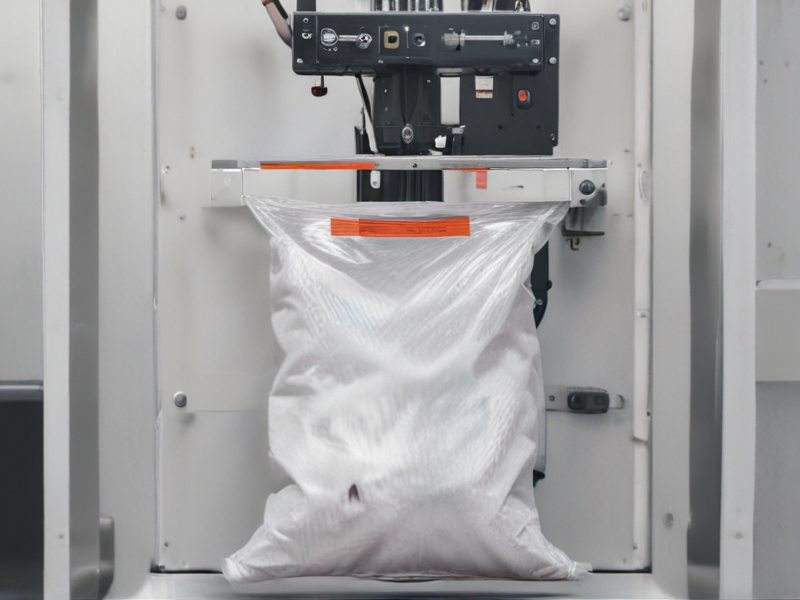

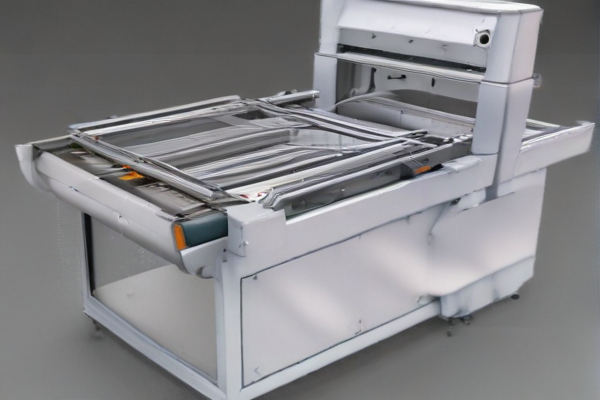

Automatic bagging systems streamline packaging processes, enhance productivity, and reduce labor costs across various industries. These systems efficiently bag products like food, pharmaceuticals, and industrial goods in both small and large-scale operations.

– Food Industry: Automate packaging for grains, snacks, produce, and frozen items.

– Pharmaceuticals: Precision in filling and packaging of pills, powders, and medical supplies.

– Retail: Efficient packaging for clothing, accessories, and consumer electronics.

– Agriculture: Handle bagging of seeds, fertilizers, and animal feed.

– Manufacturing: Automate assembly line processes for nuts, bolts, and other small components.

– E-commerce: Speed up packaging for a wide variety of online orders.

– Logistics: Enhance order fulfillment efficiency in warehousing and distribution centers.

– Chemical Industry: Safe and efficient packaging of powders, granules, and liquid chemicals.

– Automotive: Automate the packaging of small parts and accessories.

– Apparel: Efficient and uniform packaging for garments and textiles.

– Pet Food: Fast and hygienic packaging of various types of pet foods.

– Stationery: Automate packing of pens, papers, and accessories.

– Hardware: Efficient and secure packaging for tools and small hardware items.

– Beverages: Safe and efficient packing of drink powders and accessories.

– Cosmetics: Precision packaging for makeup, lotions, and skincare products.

– Cleaning Supplies: Effective packaging for soaps, detergents, and cleaning agents.

– Medical Devices: Safe and sterile packaging for various medical equipment.

– Electronics: Secure packaging of gadgets, accessories, and components.

– Toys: Speedy and durable packaging of different types of toys.

– Luxury Goods: High-quality packaging for premium products.

– DIY Kits: Efficient bundling and packaging of do-it-yourself kits and projects.

– Textiles: Safe and efficient packaging of fabrics and other raw materials.

– Bakery Products: Precision in packaging baked goods and pastries.