FAQ for Manufacturing “Automatic Linear Capping Machine Quality Work from SourcifyChina Factory”

Q1: What is an automatic linear capping machine?

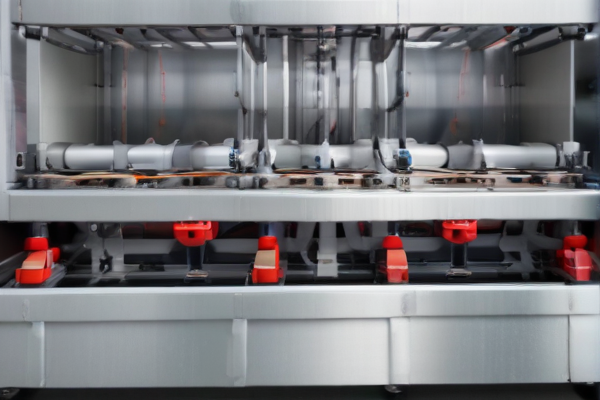

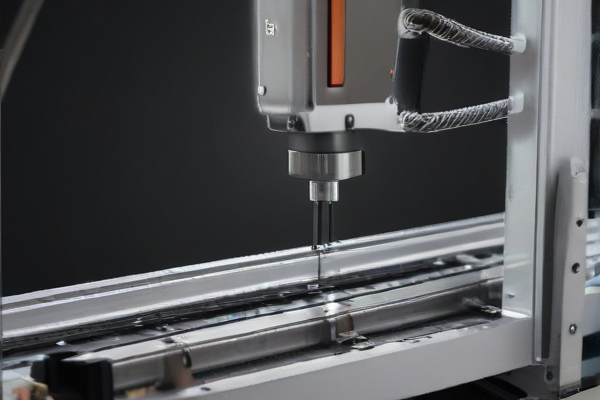

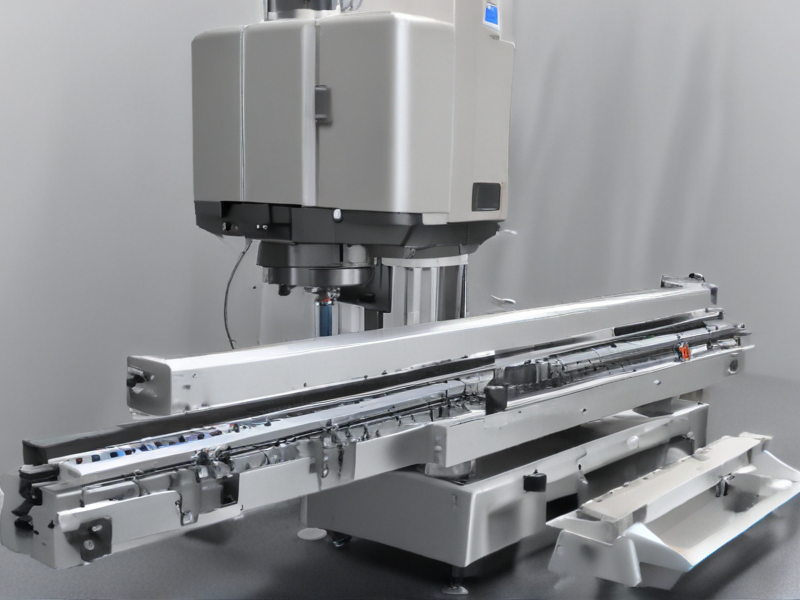

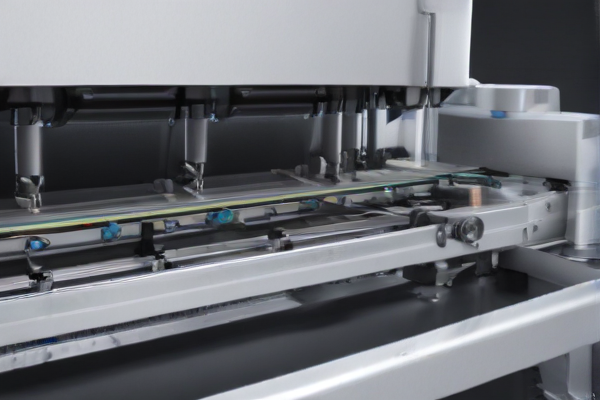

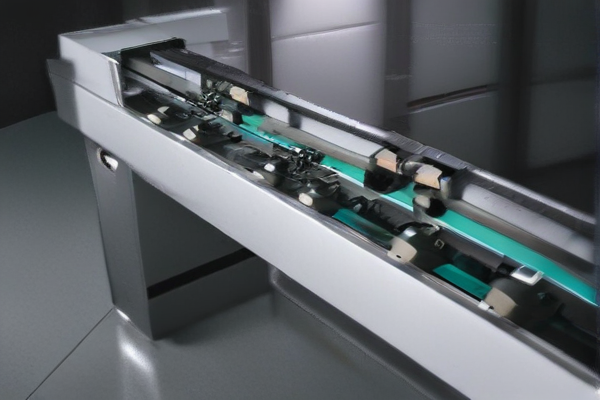

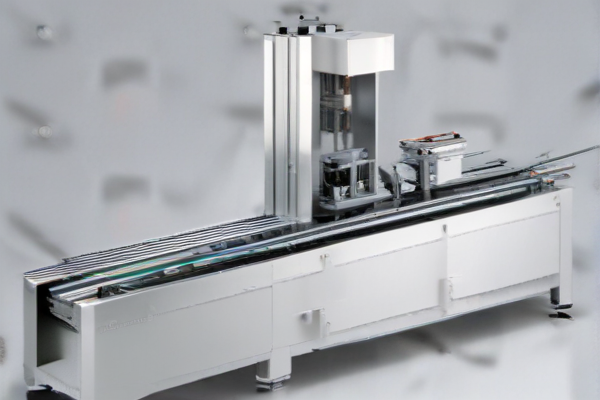

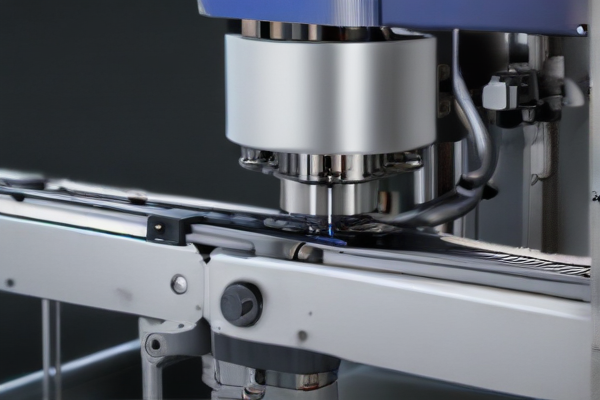

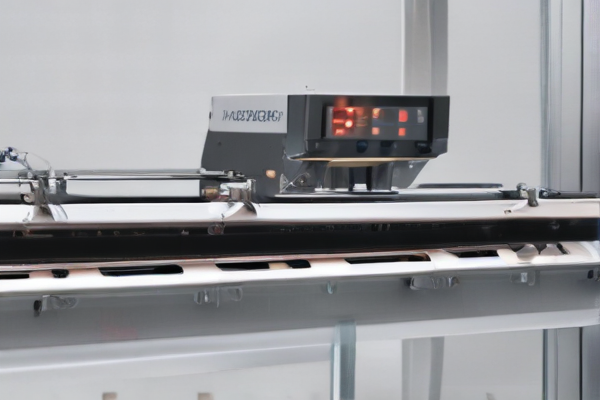

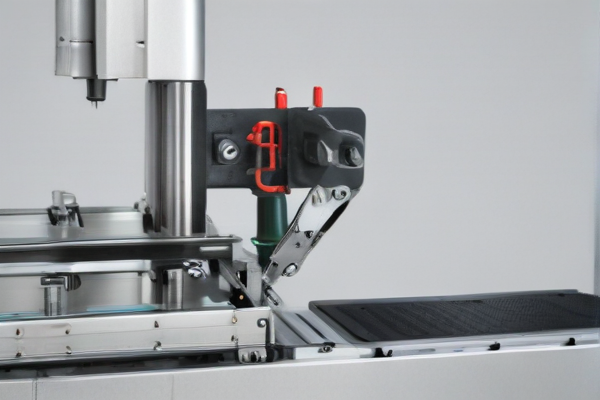

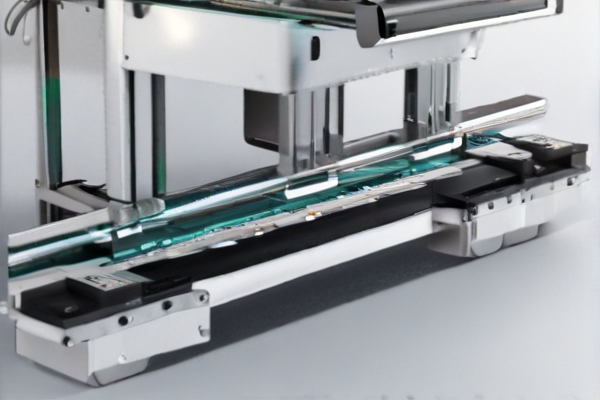

A1: An automatic linear capping machine is a device used in manufacturing to secure caps onto bottles and containers in a continuous, automated fashion, improving efficiency and ensuring consistent quality.

Q2: What services does SourcifyChina Factory provide?

A2: SourcifyChina Factory offers design, manufacturing, testing, and assembly services for automatic linear capping machines, ensuring high-quality and reliable performance.

Q3: What materials are used for the machine’s construction?

A3: The machines are typically constructed using high-grade stainless steel and other durable materials to ensure longevity and resistance to corrosion, particularly in demanding industrial environments.

Q4: How can I ensure the quality of the capping machine from SourcifyChina Factory?

A4: SourcifyChina Factory employs stringent quality control measures, including comprehensive testing and certification processes, to ensure that each machine meets international standards and customer specifications.

Q5: Are these machines customizable?

A5: Yes, SourcifyChina Factory can customize the automatic linear capping machines according to specific production requirements, including different cap sizes, bottle shapes, and production speeds.

Q6: What are the lead times for manufacturing and delivery?

A6: Lead times can vary based on the complexity of customization and order size but typically range from 4 to 8 weeks from design approval to delivery.

Q7: Do you offer training and after-sales support?

A7: Yes, SourcifyChina Factory provides comprehensive training for operators and ongoing after-sales support to ensure seamless integration and operation of the capping machine.

Q8: What is the typical production capacity of these machines?

A8: Production capacity can vary but generally ranges from 50 to 200 caps per minute, depending on the machine model and application specifics.

Q9: What kind of maintenance is required?

A9: Regular maintenance includes lubricating moving parts, checking electrical connections, and ensuring that sensors and alignment are functioning properly. Detailed maintenance guidelines are provided with each machine.

Q10: How do I place an order or request a quote?

A10: You can contact SourcifyChina Factory through their official website or customer service channels to request a quote, provide specifications, and place an order.