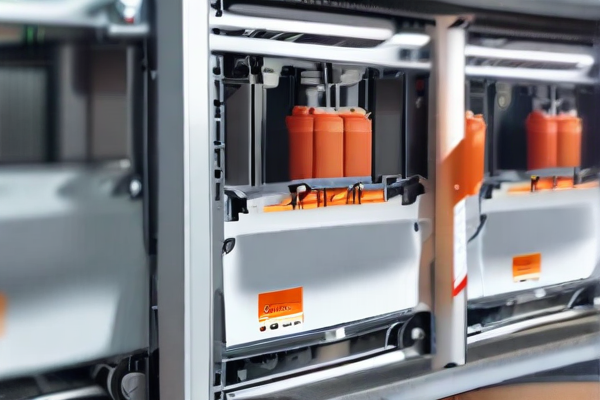

Q1: What types of automatic packaging machines does SourcifyChina factory manufacture?

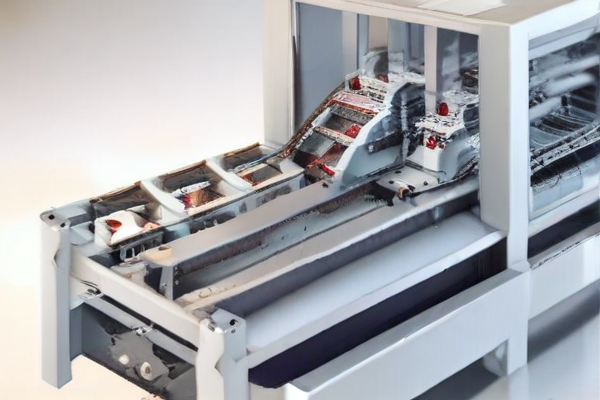

A1: SourcifyChina manufactures a variety of automatic packaging machines, including but not limited to, filling machines, sealing machines, labeling machines, cartoning machines, and palletizing machines. Each machine is tailored to meet specific industry requirements.

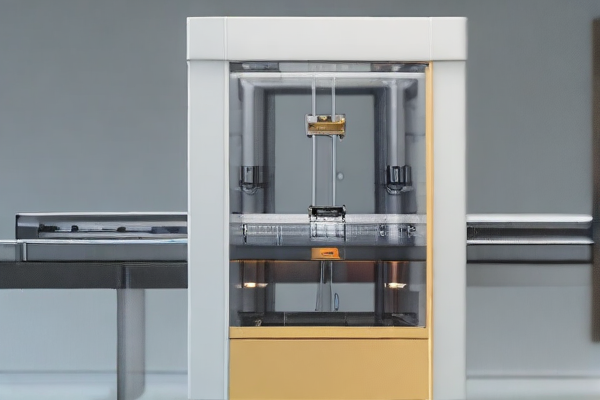

Q2: How does SourcifyChina ensure the quality of their packaging machines?

A2: SourcifyChina maintains stringent quality control measures throughout the production process. This includes sourcing high-quality materials, conducting rigorous testing, and adhering to international manufacturing standards. Additionally, every machine undergoes a thorough inspection before shipment.

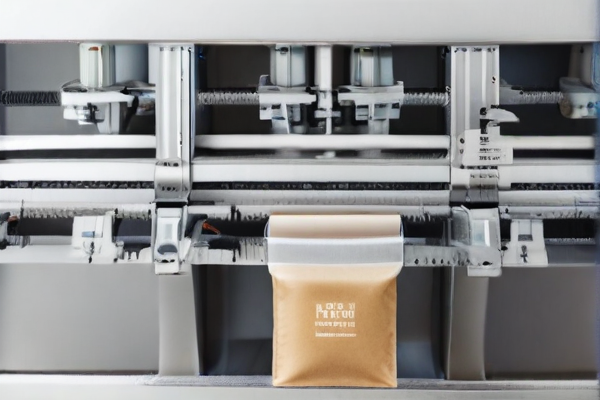

Q3: Are the packaging machines from SourcifyChina customizable?

A3: Yes, SourcifyChina offers customizable solutions to meet the unique needs of their clients. They work closely with clients to design and modify packaging machines that cater to specific requirements and production lines.

Q4: What kind of after-sales support does SourcifyChina provide?

A4: SourcifyChina offers comprehensive after-sales support which includes installation assistance, training for operators, regular maintenance services, and a responsive customer service team ready to address any issues or concerns.

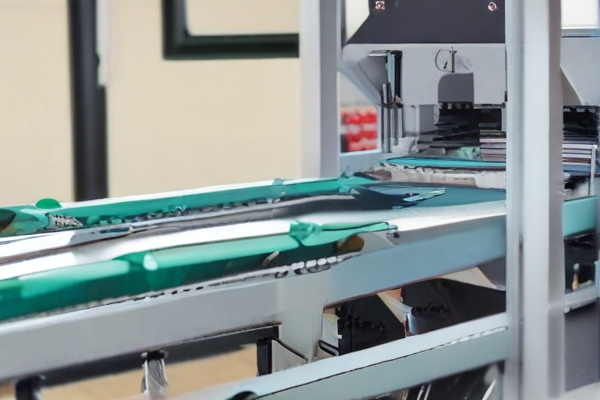

Q5: Can SourcifyChina’s packaging machines handle different types of packaging materials?

A5: Absolutely. Their machines are designed to handle a variety of packaging materials including plastic, glass, metal, and paper. SourcifyChina ensures their machines are versatile and adaptable to different production needs.

Q6: What certifications do SourcifyChina’s packaging machines hold?

A6: SourcifyChina’s packaging machines hold several international certifications such as CE, ISO, and UL, ensuring compliance with global quality and safety standards.

Q7: How quickly can SourcifyChina deliver packaging machines after an order is placed?

A7: Delivery times can vary based on the complexity and customization of the machine. However, standard models usually ship within 4-6 weeks from the date of order confirmation.

Q8: Does SourcifyChina offer any warranties on their packaging machines?

A8: Yes, SourcifyChina provides a warranty period that typically ranges from one to two years, depending on the machine type. This covers defects in materials and workmanship, providing peace of mind to their clients.

This FAQ list provides a concise overview of the crucial aspects regarding SourcifyChina’s automatic packaging machines, emphasizing quality, customization, and customer support.