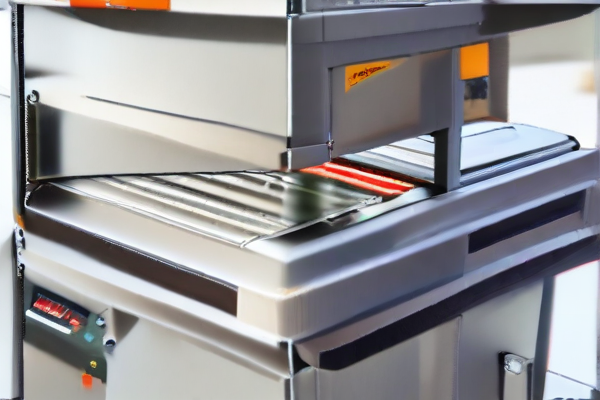

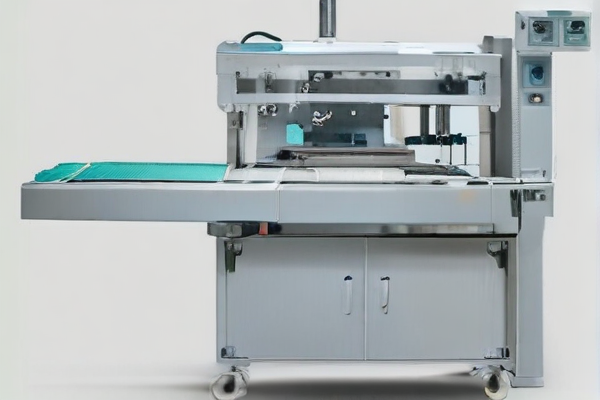

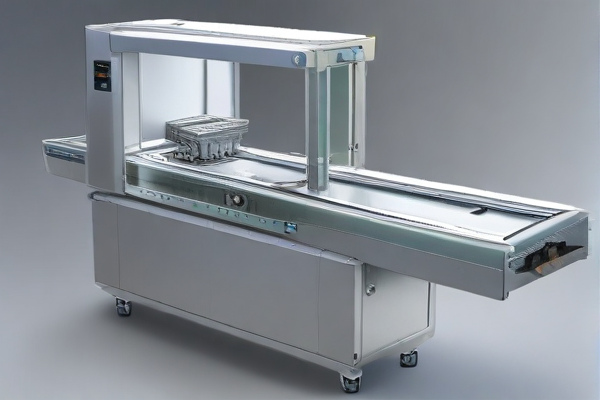

When manufacturing automatic tray sealing machines with SourcifyChina factory, there are several key tips to keep in mind.

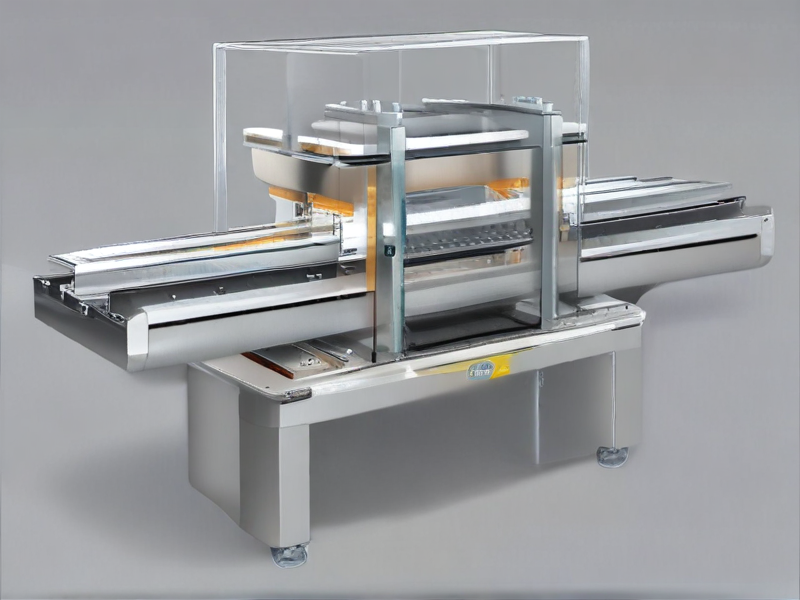

1. Clear Communication: Ensure that you clearly communicate your exact specifications and requirements to the factory. This includes the size, capacity, materials, and any specific features you want in the tray sealing machine.

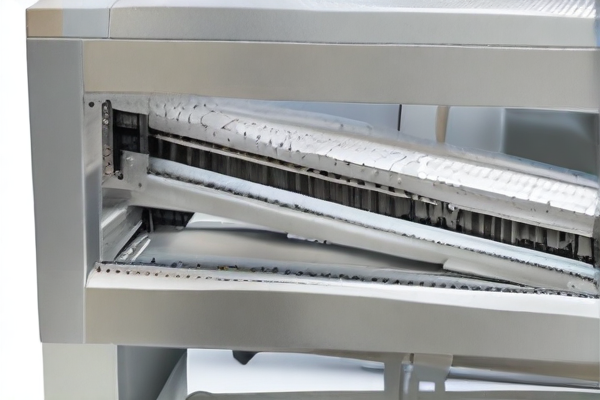

2. Quality Control: Implement strict quality control measures during the manufacturing process to ensure that the final product meets your standards. Conduct regular inspections of the production process and finished products.

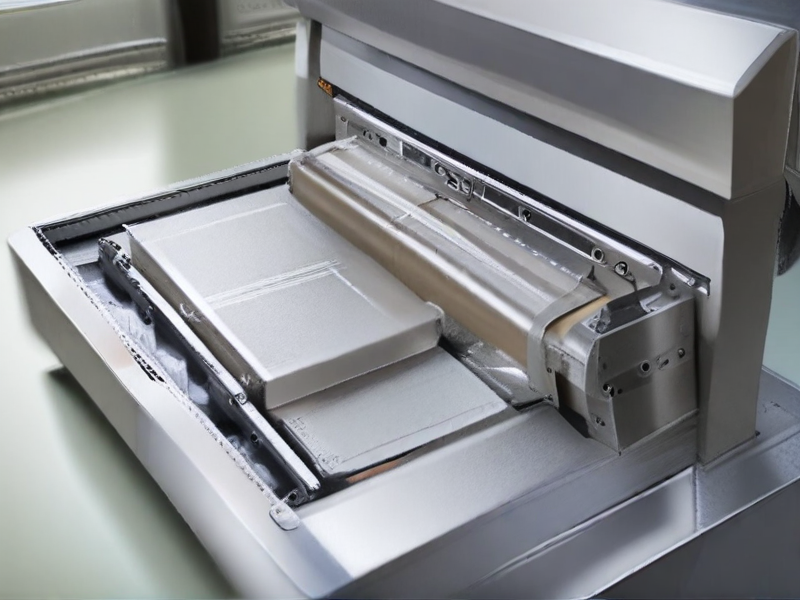

3. Material Selection: Choose high-quality materials for the tray sealing machine to ensure durability and longevity. Discuss with the factory about the best materials for your specific requirements.

4. Customization Options: Explore customization options with the factory to tailor the tray sealing machine to your unique needs. This could include branding, color options, or additional features.

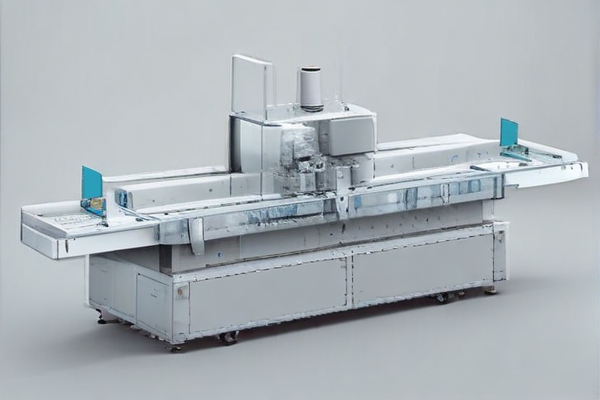

5. Testing & Certification: Ensure that the tray sealing machine is thoroughly tested and certified before shipment. This will help guarantee its safety, performance, and compliance with regulatory standards.

6. Packaging & Shipping: Discuss packaging and shipping options with the factory to prevent any damage during transit. Proper packaging will help protect the tray sealing machines during transport.

By following these tips, you can ensure a successful manufacturing process for automatic tray sealing machines with SourcifyChina factory. Effective communication, quality control, material selection, customization, testing, and packaging are all key factors in producing a high-quality product that meets your requirements.