FAQ for Manufacturing Automatic Vacuum Packaging Machines from SourcifyChina Factory

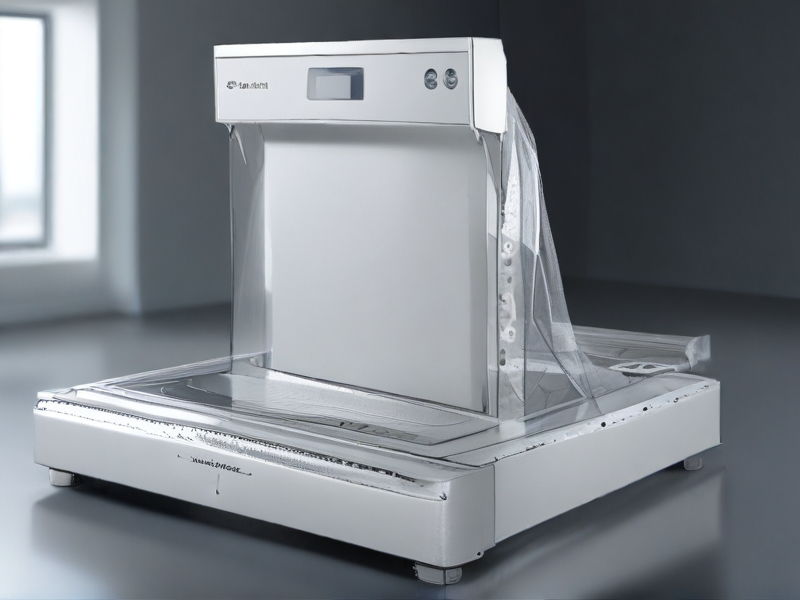

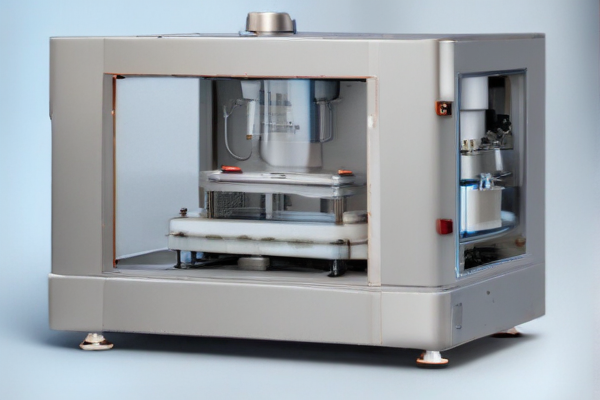

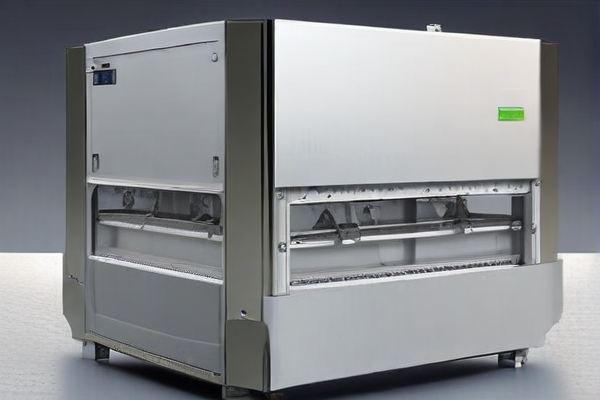

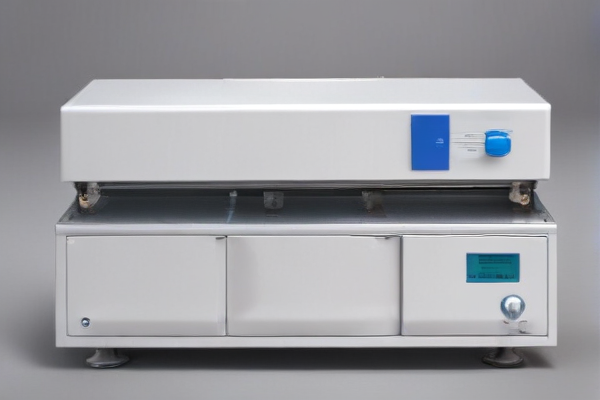

Q1: What types of vacuum packaging machines does SourcifyChina produce?

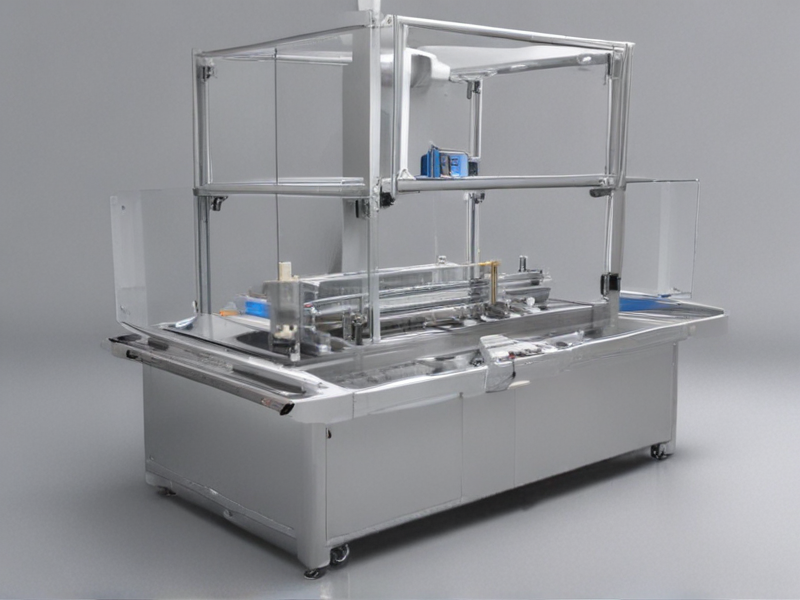

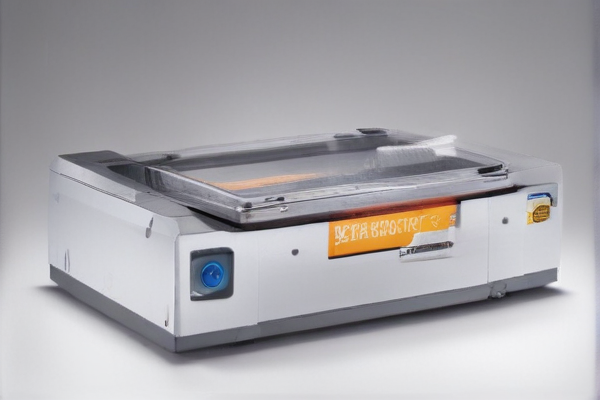

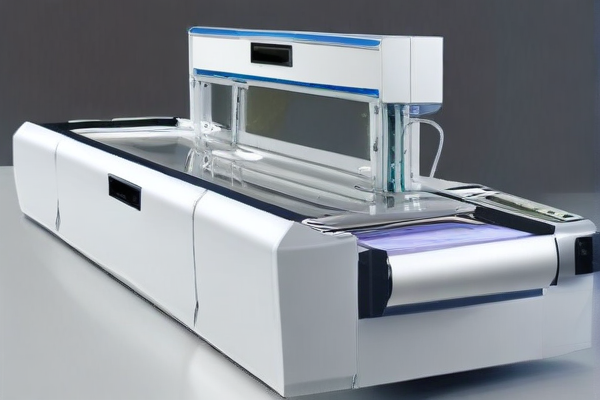

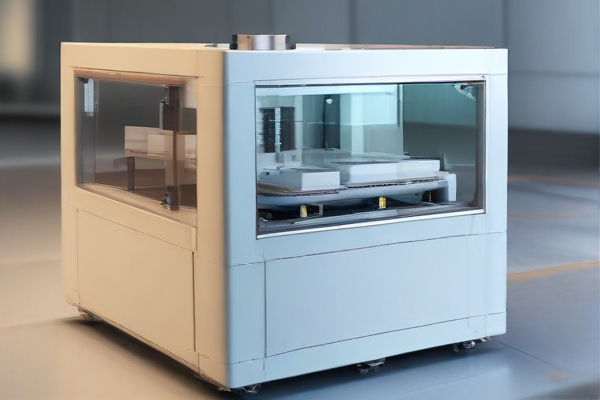

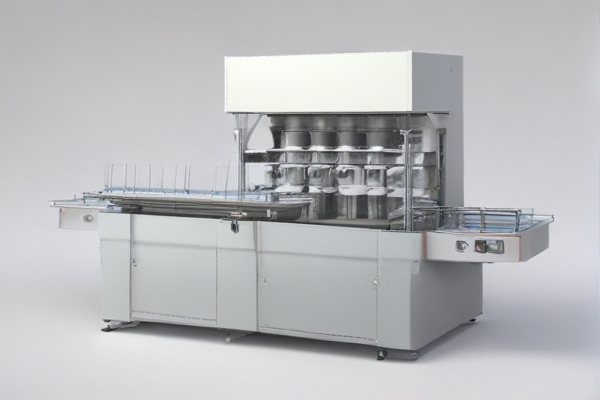

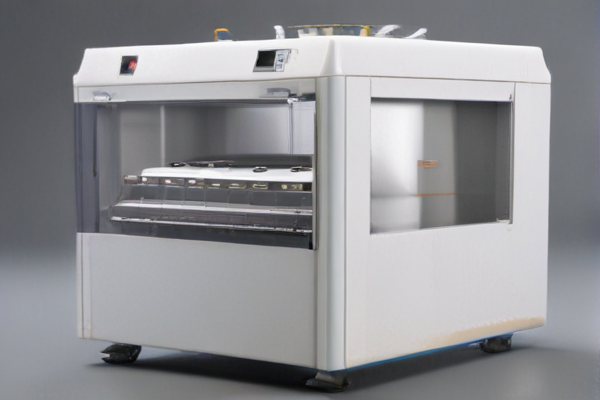

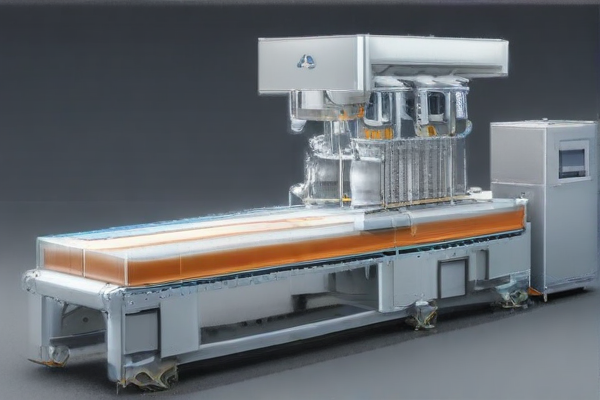

A1: SourcifyChina manufactures a diverse range of automatic vacuum packaging machines, including chamber vacuum sealers, external vacuum sealers, and automatic belt-driven vacuum packaging systems, tailored to various industrial needs.

Q2: How does SourcifyChina ensure the quality of its vacuum packaging machines?

A2: SourcifyChina implements stringent quality control measures at every production stage. This includes thorough inspections, advanced testing protocols, and compliance with international manufacturing standards ISO9001 and CE certifications.

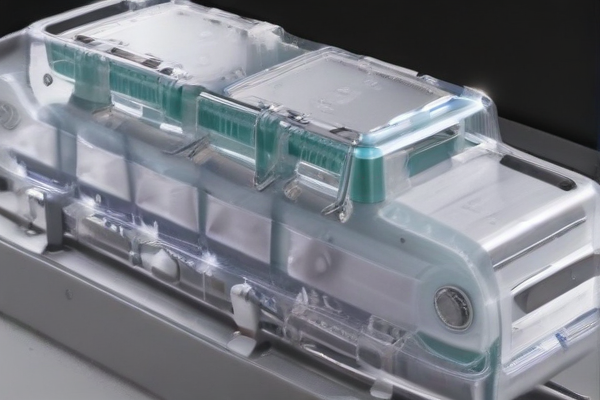

Q3: What materials are used in the construction of these machines?

A3: Our machines are primarily constructed using high-grade stainless steel, known for its durability, corrosion resistance, and ease of maintenance, ensuring a long-lasting and reliable product.

Q4: Are the machines customizable to specific industry needs?

A4: Yes, SourcifyChina offers customization options to meet specific requirements, including custom sizes, additional features, and integration capabilities with existing production lines, designed to optimize packaging efficiency.

Q5: What is the lead time for manufacturing and delivery?

A5: Standard lead times range from 4 to 8 weeks, depending on machine complexity and order volume. Promptly managing orders ensures swift production and timely delivery.

Q6: Does SourcifyChina provide after-sales support and services?

A6: Yes, we offer comprehensive after-sales support, including installation assistance, operator training, maintenance services, and a responsive customer support team to address any issues promptly.

Q7: What warranty is provided with the machines?

A7: SourcifyChina provides a one-year warranty covering parts and labor. Extended warranties and maintenance packages are also available upon request.

Q8: How energy-efficient are the machines?

A8: Our machines are designed with energy efficiency in mind, utilizing advanced technology to reduce power consumption while maintaining top performance, contributing to lower operational costs.

Q9: Can these machines handle different types of packaging materials?

A9: Yes, our machines are versatile and compatible with various packaging materials, including plastic films, laminated bags, and aluminum foils, catering to diverse packaging needs.